Date: 14 August 2025

In laminated glass manufacturing, achieving perfect edge quality and a bubble-free finish has always been a challenge—especially for high-end projects such as switchable glass or irregularly shaped panels.

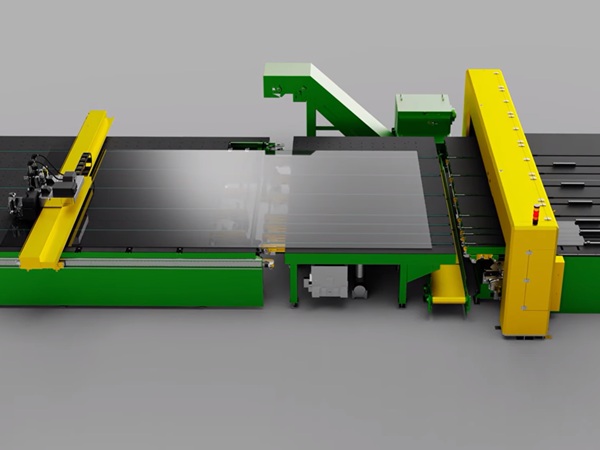

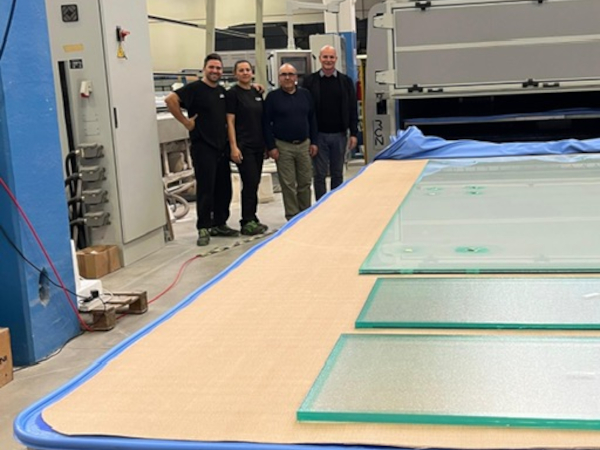

Gaoren's latest lamination process replaces traditional silicone bags with high-performance vacuum bags, delivering several key advantages:

Better Vacuum Efficiency – Vacuum bags provide superior air extraction, reducing the risk of trapped air and eliminating bubble formation.

Even Edge Pressure – Pressure distribution around the glass edges is more uniform, preventing glue overflow and ensuring a cleaner, more refined appearance.

Ideal for High-End & Complex Projects – Whether it’s switchable smart glass, shaped glass, or other premium laminated products, this method ensures optimal results with consistent quality.

By upgrading from silicone to vacuum bags, manufacturers can achieve both technical precision and aesthetic excellence—meeting the growing demands of architects, designers, and end-users in the high-end glass market.

Whatsapp : + 86 13823761190

Add new comment