Date: 18 November 2020

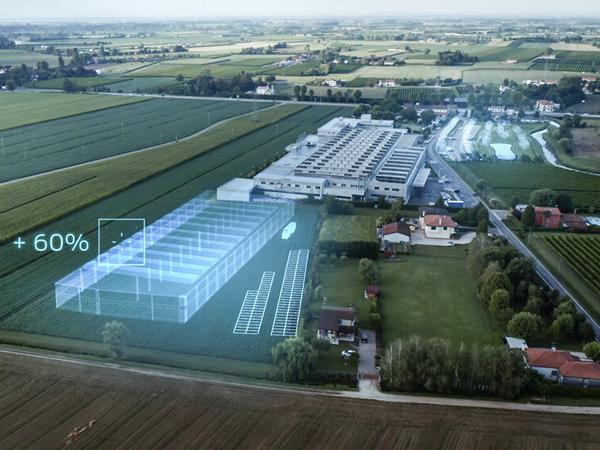

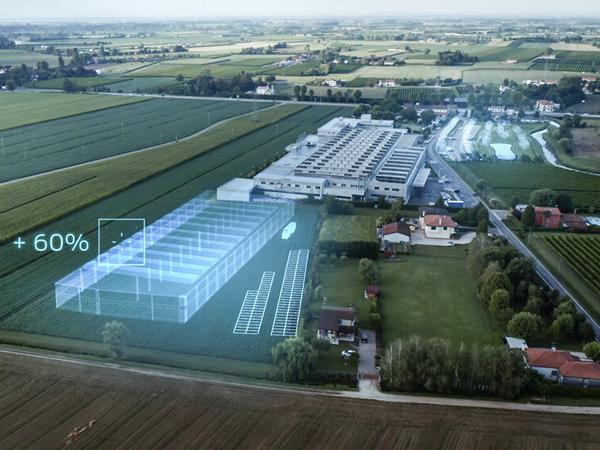

The project has been given the green light by the Municipality of Roncade, with positive opinions expressed by the various bodies involved in the process; it will see the construction of a new building spanning an additional 8,000 square metres, 60% more than the current production area. The project will also involve the surrounding access roads, with the creation of a public and private car park and a public green area equipped with facilities.

Founded in 1976, today Forel is one of the leading manufacturers of glass processing solutions in the world, with exports to over 70 countries across the globe and a degree of technological edge that is recognised internationally. The company, which is constantly growing, has planned this significant investment in order to meet the growing number of existing orders without having to move part of its production activity to other sites: this will result in greater efficiency and faster production times, while ensuring the same quality of the finished product, strictly "Made in Italy".

"Throughout its history, Forel has always increased its size on the market, year upon year," explain Fortunato and Riccardo Vianello, the owners of the company. "As a result, we have found ourselves needing ever larger work spaces. This next development, however, is set to be very substantial, and will serve to further increase our competitiveness."

The increase in size of the site provides greater scope for the various production departments, which today specialise in Vertical Processing (arrissing, grinding, polishing, drilling and milling), Sorting Solutions for automated production enviroments within the glassworks, Vertical Cutting Lines for Laminated Glass, PVB Laminating Lines and Insulating Glass Lines.

600450

600450

Add new comment