Date: 30 July 2025

Milan alone would be reason enough to travel to the Vitrum trade fair. In addition, there are trends to discover that can transform a mere visit into a real experience. The HEGLA Group is among the exhibitors: on display are solutions for cutting and automatic handling of thin glass, a new laminated safety glass (LSG) cutting system, laser processing options and the glass365 ERP system.

Trend topic: Thin glass in triple glazing

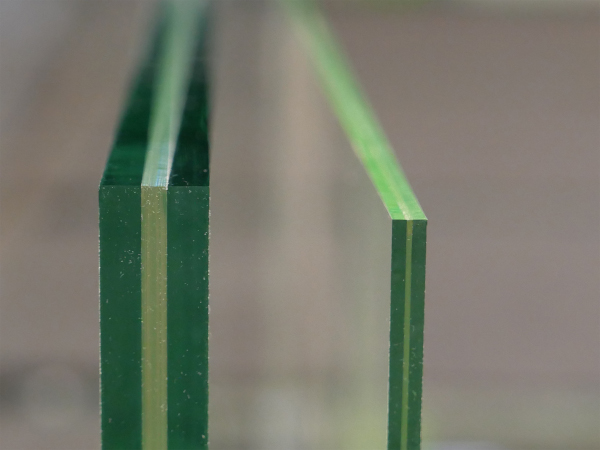

Thin glass is a trending topic in the industry. While triple glazing made of soda lime glass panes has been an established component of energy-efficient buildings, glass as thin as 0.5 mm in the middle position offers new potential. Thanks to its slim design and light weight, existing double glazing can be replaced with triple glazing during renovations. The U-value is comparable to that of conventional triple glazing. The combination also offers advantages in new buildings. The design is narrower and lighter, reducing the load on the building structure and fittings.

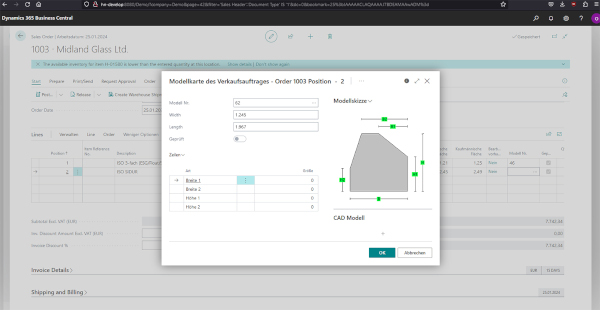

Homogeneous cutting edge for high edge strength

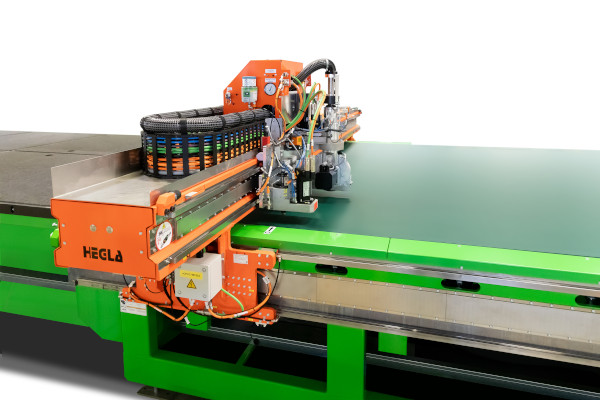

Up to now, thin glass has been widely used for technical applications. The borosilicate glass typically used for this purpose is more heat-resistant and break-proof than float glass. On the other hand, the demands on handling and edge quality are greater. "A high degree of automation and adapted processes ensure process reliability here," says HEGLA Managing Director Bernhard Hötger. "A special cutting head takes care of everything else, achieving a homogeneous cut edge with high edge strength." After automatic transfer to a harp rack, an insulating glass unit with TPS spacers is then produced on a Glaston line, for example.

System evolution for laminated safety glass

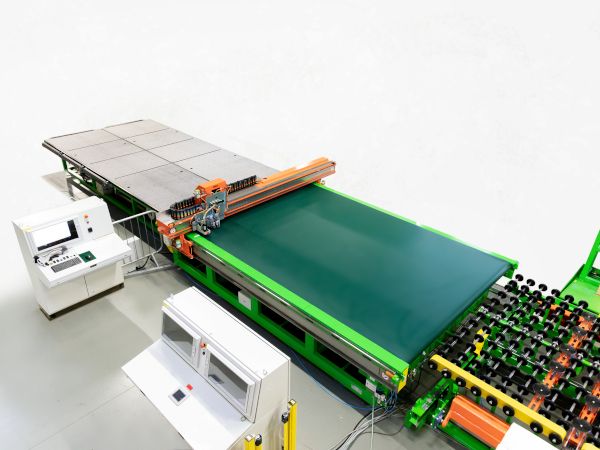

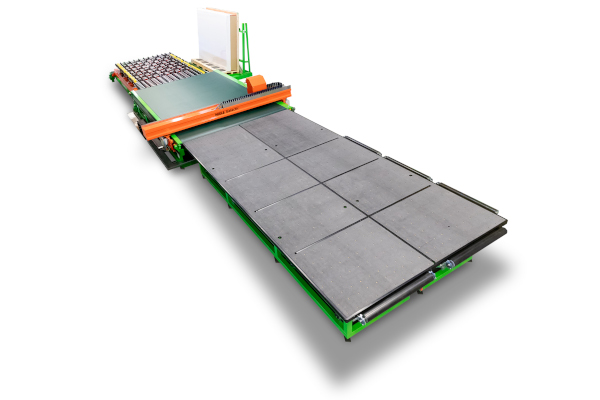

A newly developed cutting table for laminated safety glass is to be exhibited for the first time. "We have combined the best features of AdvaLam and ProLam and taken them to an even higher level", emphasises Bernhard Hötger. "The result is a system that works autonomously in fully automatic mode with maximum throughput and cycle times." In conjunction with automatic glass transfer, a glass flow is created that is system-controlled and specified by the machine. Productivity can be increased by 20 per cent, thanks to optional laser diode heating. With this new development, it is no longer the operator but the machine that sets the cycle.

Added value with laser

Whether it’s bird protection, RF transparency or heatability: laser processing adds value to standard glass. A bird protection pattern can be printed during production or later on the building. The effect is threefold: it makes it impossible for birds to fly through. The pattern interrupts reflections from trees and bushes, for example. As an additional warning, a reflection is created that is only visible to the bird. The finish is applied without damaging the surface. Ceramic particles are transferred to the glass, which remain scratch-resistant, weather-resistant and colourfast for over 20 years.

Other innovations include laser edge coating. The coating is removed with the highest optical quality without damaging the surface. The 'UC-Stamp line' is also being presented at the stand for the first time. The laser professionals from Halle are presenting a new laser marking system that is lightweight and more compact, designed to make it easier to get started with the technology.

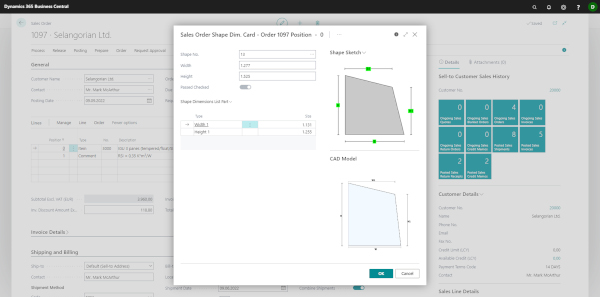

The latest generation of ERP

The HEGLA-HANIC is presenting its new 'glass365' ERP system. The Bochum-based specialists have completely redesigned the existing ERP system based on Microsoft Dynamics 365 Business Central. "This allowed us to transfer the strengths of our programme and our glass expertise into a state-of-the-art software structure," explains Dr Jan Schäpers, Managing Director of HEGLA-HANIC. "This gives us the freedom to focus on our core competence, while our users benefit from modern interfaces and numerous connections to Office 365, for example." The software is device-independent, receives automatic updates, and is scalable to other applications, products and even multiple locations. Add-ons are available in Dynamics App Source. Customer orders, for example, can be transferred to the system via data import or app. Among other things, an activatable AI tool is also available, which reads orders from email attachments in Office 365, for example. After user approval, the data is transferred to the system, and optional evaluations are provided or AI-supported marketing measures suggested. HEGLA-HANIC currently has a new MES/PPS in the starting blocks: anyone who would like further information or is interested in how to respond independently and system-controlled to events in production in the future should stop by HEGLA-HANIC.

The HEGLA Group can be found at stand 21 in hall 9.

600450

600450

Add new comment