13- 121, 507 Teheran-ro

Gangnam-gu 06169 Seoul

South Korea

LiTROS

LiTROS is a brand of the LiSEC Group, which provides a simple and inexpensive entry into the world of industrial glass processing — with a well-thought-out range of products and integrated solutions throughout the entire production process.

You benefit from high-quality entry-level products and comprehensive service and consulting. With LiTROS do you have a reliable partner who will accompany you on your path to partial automation and future-proof your production processes.

With LiTROS, you have a reliable partner who will accompany you on your path to partial automation and make your production processes future-proof. Stay tuned and visit our website regularly, as the product portfolio is constantly being expanded to meet the needs of our customers even better.

Main address:

LiTROS

13- 121, 507 Teheran-ro, Gangnam-gu

06169 Seoul

Republic of Korea

+ 827047844003

office@litros.com

Second address:

Lumplgraben 49

4463

Austria

+43-7254-8100

Products

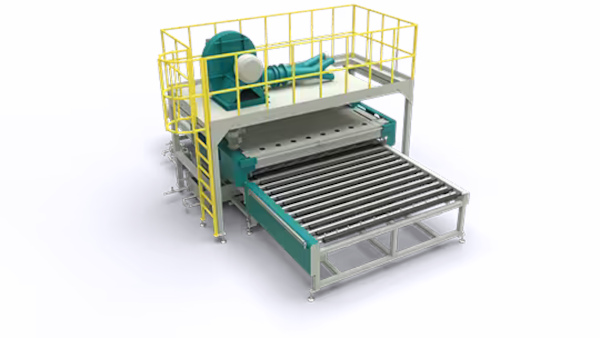

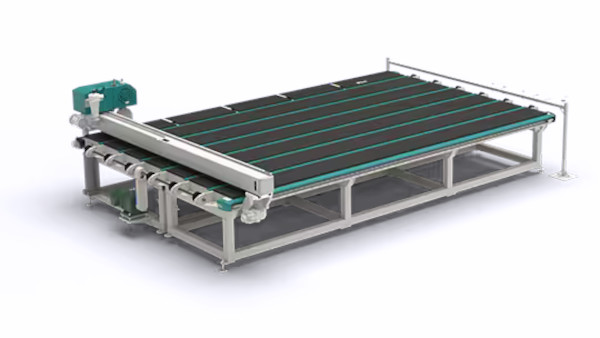

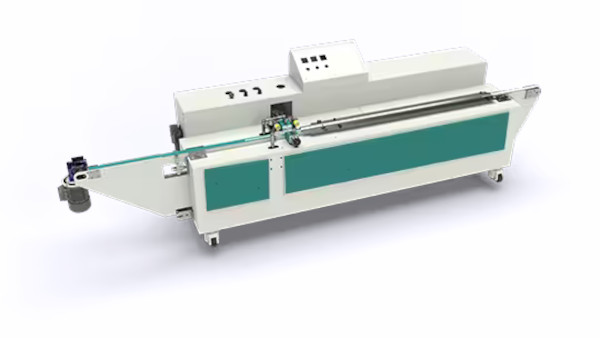

LiTROS Horizontal Washer

The LiTROS glass washing and drying facility guarantees effective cleaning of flat glass.

It is a glass washing and drying system that was specially developed for the efficient cleaning of flat glass. It offers reliable glass cleaning and is available in three versions for processing different maximum dimensions:

- Up to 3600 mm x 2400 mm

- Up to 5000 mm x 3000 mm

LiTROS Topclear Eco

Washing machine for flat glass processors with stainless steel components and optimal adaptation to Topdrill machines.

LiTROS Topclear Eco is the basic device for commercial glass processors and offers an unbeatable price/performance ratio. All parts that come into contact with water are made of stainless material. The machine is already completely complete and practical as standard. The transport height is optimally tailored to Topdrill processing machines; of course, vertical third-party machines can also be connected using different transport heights.

LiTROS Topclear Special

Professional glass washing system for glass thicknesses up to 12 mm with optimal maintenance access and modular configuration.

LiTROS Topclear Special is the perfect washing system for commercial and industrial glass processing — when large glass thicknesses are not required. A particular advantage is the extremely easy accessibility for particularly easy maintenance. LiTROS Topclear Special can be configured very individually — particularly for solar production and multi-shift operation.

LiTROS Topclear Super

Washing machine for processing thick glass up to 20 mm.

LiTROS Topclear Super is for Washing optimized for thicker glasses, particularly in the grinding sector. All glass thicknesses up to 20 mm can be processed without further adjustment. Die LiTROS Topclear Super is available in sizes 1,600 mm, 2,000 mm and 2,500 mm.

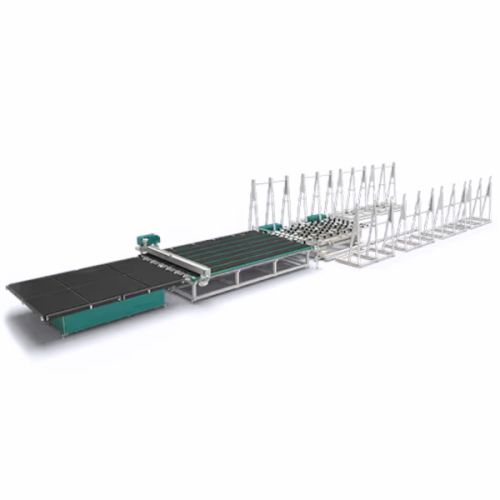

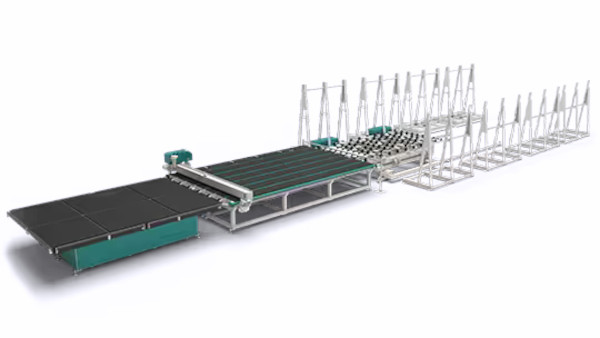

LiTROS Cutting Line

This exemplary LiTROS glass cutting line is a sophisticated, modular solution for industrial processing of float glass. It consists of three perfectly coordinated stations: LiTROS Load, LiTROS Float Cut and LiTROS Float break.

The LiTROS glass cutting line is a sophisticated, modular solution for industrial processing of float glass. It consists of three perfectly coordinated stations: LiTROS Load, LiTROS Float Cut and LiTROS Float break. This line enables a continuous process from loading to cutting up to breaking the glass panes.

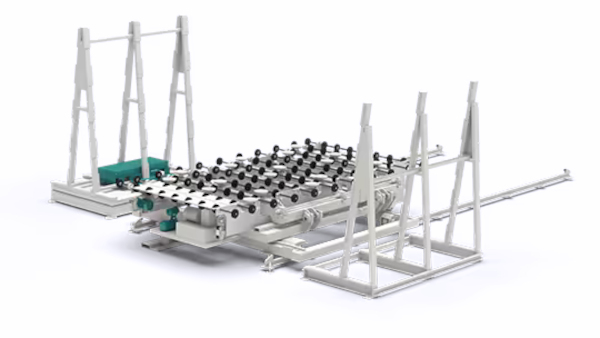

LiTROS Load

The double sided, stationary LiTROS glass collection station was specially developed for the removal of raw dimensions.

The LiTROS Load is a double sided, stationary glass collection station that was specially developed for the removal of raw dimensions. It enables the handling of glass panes up to a maximum size of 3700 x 2700 mm/6000 x 3210 mm and offers efficient glass processing.

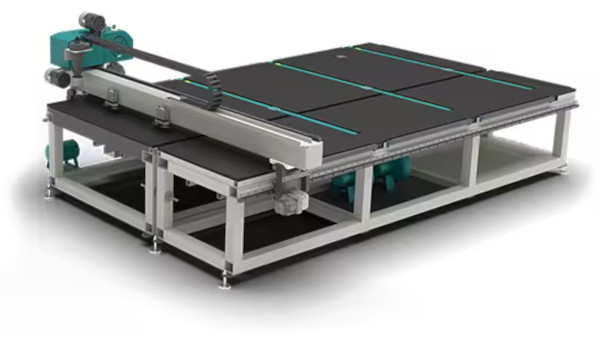

LiTROS Float Cut

The reliable glass cutting system from LiTROS for cutting and decoating float glass.

The LiTROS Float Cut is a glass cutting system that was specially developed for cutting and decoating float glass. It enables cutting of glass panes up to a maximum size of 3700 x 2700 or 6000 x 3210 mm.

LiTROS Float Cut-Tilt

The LiTROS glass cutting system for cutting and decoating float glass with tilting elements.

The LiTROS Float Cut-Tilt is a glass cutting system with tilting elements, which was specially developed for cutting and coating float glass. It enables cutting from glass panes up to a size of max. 3700 x 2700 mm and offers precision and efficiency in glass processing.

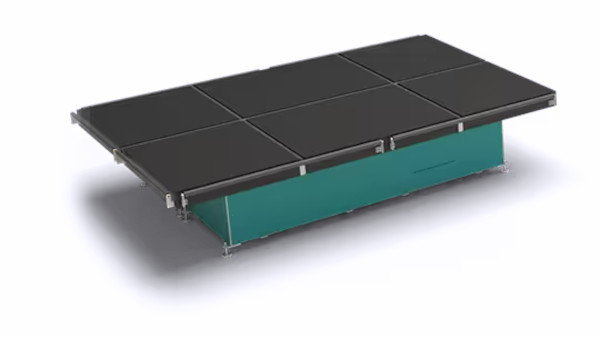

LiTROS Float Break

The LiTROS system for manually breaking float glass sheets.

The LiTROS Float Break is a system for manually breaking float glass sheets.

Lines

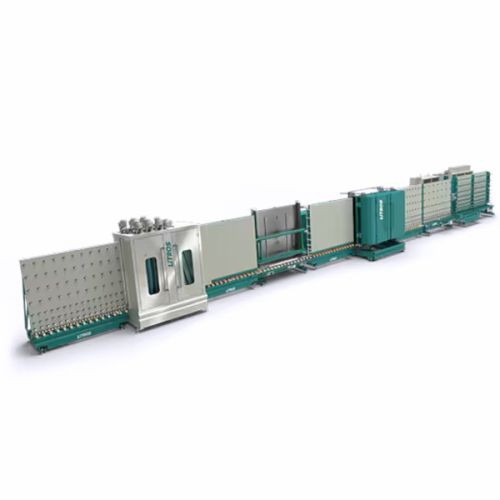

LiTROS IG Line Rigid

Vertical LiTROS insulating glass line for manufacturing insulated glass units with rigid spacer frames.

The vertical LiTROS insulating glass line offers a good solution for the efficient production of insulating glass units with rigid spacer frames. It combines solid technology with a sophisticated and robust design. Reliability and ease of use are guaranteed. The line is available in three different versions, which relate to the maximum processing size:

- 2400 mm x 1800mm

- 3600 mm x 2400 mm

- 6000 mm x 3000mm

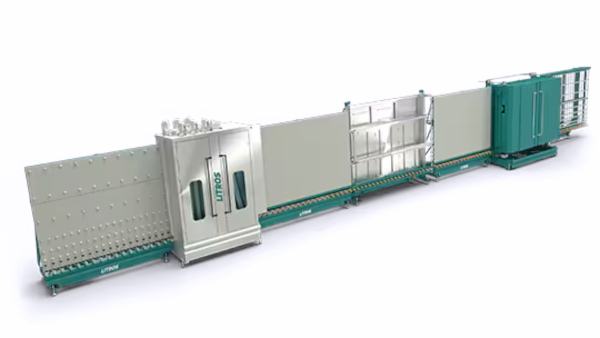

LiTROS IG Line Rigid-Seal

Vertical LiTROS insulating glass line with sealing for manufacturing insulated glass units with rigid spacer frames.

The vertical LiTROS insulating glass line with sealing offers a good solution for the efficient production of insulating glass units with rigid spacer frames. This reliable line combines modern technology with robust design. It is available in three versions for processing different maximum dimensions:

- up to 2400 mm x 1800 mm

- up to 3600 mm x 2400 mm

- up to 6000 mm x 3000 mm

Stand alone

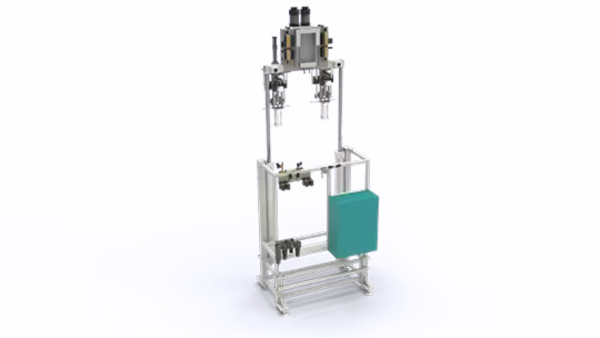

LiTROS IG Seal Manual

Pumping and dosing system for the manual application of secondary sealants in insulating glass production.

The LiTROS IG seal manual provides an efficient solution for the manual application of secondary sealants in insulating glass production. This system combines modern technology with a robust design to ensure reliable use.

LiTROS IG Dessicant Manual

System for manually filling rigid spacers with desiccant.

The LiTROS IG desiccant manual offers a practical solution for manually filling fixed spacers with desiccant. This user friendly station combines sophisticated design with easy handling to ensure reliable filling.

LiTROS Dessicant Automatic

A smart solution for automatically filling rigid spacers with desiccant.

The LiTROS IG Desiccant Automatic offers a smart solution for filling fixed spacers with desiccant. This reliable station combines modern technology with a robust design.

LiTROS IG Butyl Semi Automatic

Semi automatic coating extruder for applying spacers with butyl hot melt adhesive.

The LiTROS IG butyl semi automatic provides an efficient solution for coating spacers with butyl hot melt adhesive. This easy to use station combines robust technology with sophisticated design.

LiTROS IG Cleaning Pump

Flushing pump for the automatic cleaning of sealing systems

The LiTROS IG Cleaning Pump offers a robust solution for cleaning components that come into contact with sealing material – such as mixing lines, hoses , and pipes. The pneumatically controlled pump unit is connected directly to the mixing line of an automatic sealing robot or a two-component extruder. A special cleaning agent is pumped through the system, ensuring thorough cleaning of the mixing zone and the reliable removal of material residues . Cleaning agent capacity: 20 l

LiTROS IG Frame Hanger

Transport station for butylated spacer frames.

The LiTROS IG Frame Hanger horizontal conveyor offers a robust solution for the manual loading and transport of spacer frames within the production line. The freestanding station is specifically designed to hold butylated frames, which are hooked onto the conveyor rails. Transport is via a manually controlled foot pedal drive to the defined end position, where the frame is removed and fed to the next work step – frame setting.

Technical Data

- Minimum frame size: 400 × 200 mm

- Maximum frame size: 3500 × 2300 mm

- Conveyor bars: 19 (standard), each with 7 insertion hooks

- Design: Freestanding, without lifting function

Lines

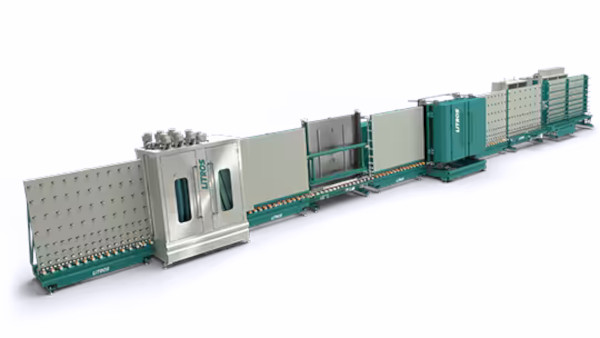

LiTROS Combifin

Vertical LiTROS Insulating glass line for manufacturing insulated glass elements with rigid spacer frames.

LiTROS Combifin is the fastest and easiest way to vertically process medium-sized glass formats while maintaining optimum cycle time and efficiency.

Stand Alone

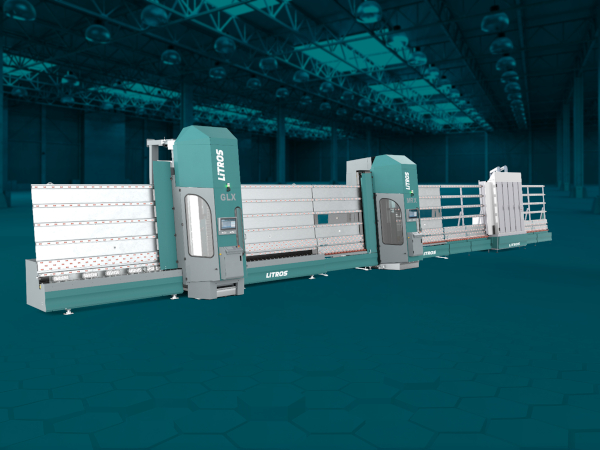

LiTROS GLX 3220 P1 Eco

CNC-controlled grinding and polishing machine for rectangular glass panes and special shapes with easy operation and fast cycle time.

The LiTROS GLX P1 grinds and polishes glass edges quickly, fully automatically and with CNC control. Rectangles and special shapes with thicknesses of 3 — 12 mm and up to a format of 3210 x 2000 mm are processed.

Advantages of massively built LiTROS GLX are easy to operate and easy to maintain. In addition, the machine can be installed as a single device or in combination with a Combifin processing line.

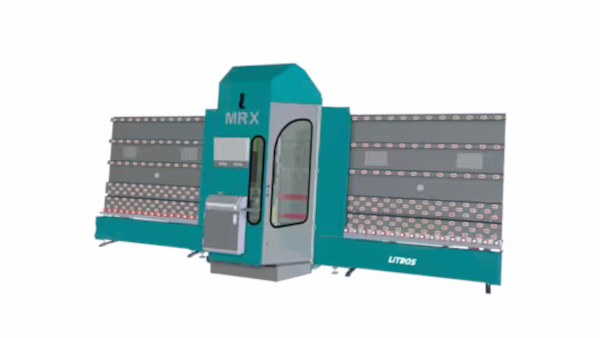

LiTROS Topdrill M-RX G7

Vertical drilling and milling center with waterjet option and extremely fast tool changes for flexible glass processing.

The M-RX is a flexible and fast drilling and milling center for double-sided glass processing — now with the option of an integrated waterjet head. A 10-way tool change head is mounted at the front and rear. During processing, the glass is fixed to the back using vacuum belts. The system impresses with fast cycle times and can be installed as a single machine or in a processing line.

LiTROS Topdrill NC G8

Vertical single-head drilling machine for flat glass with waterjet option, ideal for series with the same drilling diameters and modularly expandable.

The LiTROS Topdrill NC G8 is comparatively compact. The configuration can be adapted as required. The machine is ideal for drilling individual pieces or series with the same drilling diameters. In conjunction with the optional waterjet head, surface and edge sections can also be created very economically.

The LiTROS Topdrill NC G8 can be installed as a single device or as part of the Combifin line. It can be extended at any time with a Topclear washing machine.

The machine is available in two versions:

- LiTROS Topdrill NC 14 G8

- LiTROS Topdrill NC 25 G8

LiTROS Topdrill RX G8

Turret head drill for flat glass with automatic tool change during processing, ideal for series and individual pieces.

Thanks to the eight-fold turret, Topdrill RX G8 is perfect for quickly drilling and lowering flat glass, and can also create surface and edge cuts very economically thanks to the optional waterjet head.

Like all G8 systems, the RX can be used as an individual device or as part of the COMBIFIN line.

LiTROS Topdrill RX G8 is available in two versions:

- Topdrill RX 14 G8

- Topdrill RX 25 G8

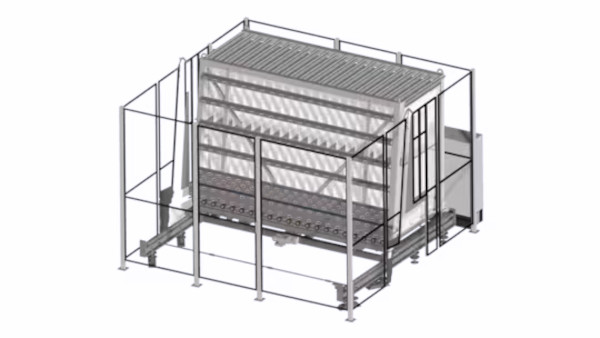

LiTROS SSP-A

Sorting and storage buffer for vertical lines with 30 storage compartments for flat glass and fully automatic, unmanned loading to avoid downtime.

The LiTROS SSP-A sorting and storage buffer is the ideal addition to vertical processing machines. The system offers 30 individually controllable storage compartments, and each compartment can be filled with up to 4 glasses. Loading is carried out via loading modules or directly via the processing machine. The particular advantage of SSP is the completely unmanned loading, which prevents unnecessary downtimes.

The SSP-A is available in two sizes and can be used for loading or unloading.

Accessories

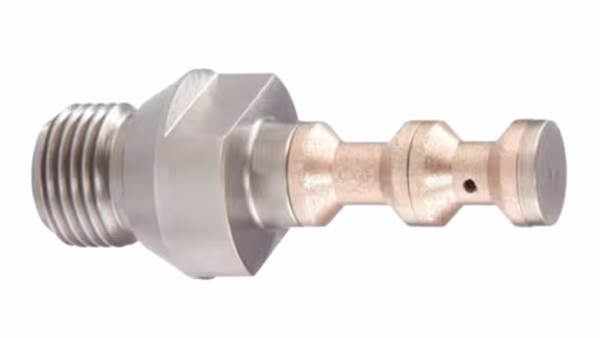

LiTROS Innodia Classic Line

Proven drilling and countersinking tools with a high diamond concentration and rust-proof design for daily use.

The LITROS Innodia Classic Line comprises high-quality drilling and combination countersinking tools, which have been specially developed for daily use in flat glass processing. Thanks to their robust construction and sophisticated details, they offer excellent value for money and are available at short notice.

LiTROS Innodia Combi Line

Combined milling tools for glass with two positions on one tool to reduce set-up times.

The Combi Line primarily offers combined milling tools for glass. These special tools are particularly suitable for vertical machining centers such as the Topdrill M-RX or comparable devices. Two different positions on a single tool reduce tool change times and ensure increased productivity.

LiTROS Innodia Special Line

High-performance sinking and milling tools with asymmetrical cooling and fine diamond grit for maximum performance.

Special tools such as high-performance countersinking and milling tools are used in LiTROS Innodia Special Line in a nutshell. In contrast to similar products, you can expect an uncompromising focus on top performance with these tools. The depth sinks and milling tools for glass are equipped with asymmetrical cooling holes to really cool all processing surfaces. The diamond grain is fine enough for clean processing and the increased diamond concentration guarantees fast work.

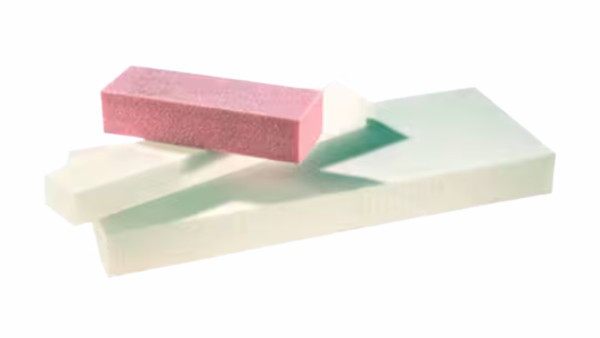

LiTROS Innodia accessories

Practical accessories such as sharpening stones, drill magazines and quick-change systems to increase productivity.

LiTROS Innodia is not just a brand for innovative and high-quality diamond tools. Of course, necessary and particularly practical accessories are also promptly available from stock. High-quality tools must also be stored safely and clearly and sharpened as needed. As a result, you can increase your productivity and the attractiveness of your workplaces!