Date: 6 July 2020

As a dated and experienced manufacturer of glass machinery, R.C.N. SOLUTIONS has come to the conclusion the chemical tempering of the glass is open to several advantages and different applications.

As a dated and experienced manufacturer of glass machinery, R.C.N. SOLUTIONS has come to the conclusion the chemical tempering of the glass is open to several advantages and different applications.

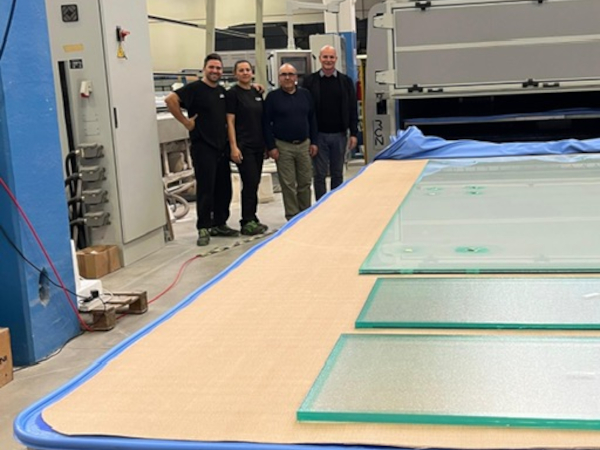

CT900 - Chemical tempering plant,"RIVA by RCN"

The process is preferred for all those jobs where thin tempered glass is demanded, a limitation the thermal tempering ovens cannot overcome, albeit some manufacturers have recently extended the thermal tempering to thin glass as well. However, the optical quality is far to be equal to the glass chemically tempered, because the chemical process does not provoke distorsion on the glass surface, not a minor detail , and not the only benefit.

The chemical process consists of submerging the glass into fused potassium salt bath and exposing the glass to an ion exchange process, at a temperature of 450°C.

The process provokes a space reduction between the glass particles that are compressed by the bigger size of the potassium ions. The glass surface is under compression (300/400 N/mq) while the core is not in compensating tension.

Thou the chemical tempering requires more time process than the thermal one, the advantages are significant: glass chemically tempered can be processed later - drilling, cutting, edging, polishing, sandblasting; curved glass can also be tempered, special curves in particular. The absolute flatness is essential for the lamination process and the lack of distorsion is a crucial matter in some architectural projects too.

For this reasons RCN, in cooperation with an expert having more than 40 years experience in manufacturing chemical tempering plants, has developped its new chemical tempering line, "Riva by RCN" and it is not by chance that international companies such as AGC, Schott, Europtec and Luxottica have chosen RCN as supplier.

This new line perfectly matches with the other RCN machines combining a full production "team": bending, tempering and lamination. The winning solution resonding to the latest market requirements, but also granting a free access to several, different applications, giving your products the high added value you are looking for.

R.C.N. SOLUTIONS SRL - Italy

600450

600450

Add new comment