Date: 2 June 2021

The physical properties of flat glass can be influenced by targeted heat treatment. For example, single-pane safety glass (SPSG) is produced by so-called thermal tempering. In this process, the panes are first heated uniformly to more than 600 °C in an oven.

This is followed by a cooling period in which air is blown in for abrupt cooling. Precise maintenance of the slightly different temperatures in the oven, depending on the type and thickness of the glass, is crucial for the desired quality of the end product. This involves both the exact temperature and the most homogeneous temperature distribution possible within the glass panes.

Optris has now developed a special system for this process. It is based on the PI 640 IR camera and can be used on any glass tempering system thanks to selectable optics with different aperture angles.

The challenge of Low-E glass

In order to achieve high energy efficiency in buildings, so-called Low-E glass is standardly used for windows and facade components.The windows designed as multi-pane insulating glass have a coated side with a very low emissivity, which leads to reduced heat radiation in winter and low heating of the rooms by solar radiation from outside in summer.

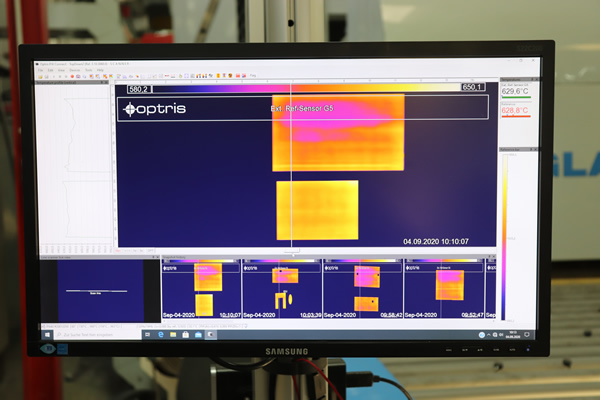

However, the low emissivity poses a major challenge for the infrared measurement technology used. The new Top Down GIS 640 R solves this problem with a special configuration: Above the glass, at the exit of the oven, an infrared camera type PI 640 is installed, which quickly determines with high resolution the temperature distribution of the individual panes over the entire system.

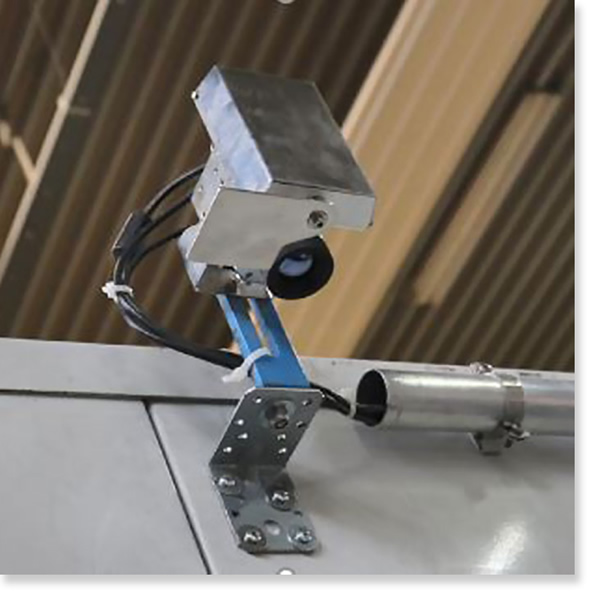

Below the glass – i.e. on the side without the Low-E coating – a CT G5L pyrometer reproducibly measures the exact glass temperature. The individual pixels of the IR camera image are referenced to this measured value. This enables automated emissivity correction for standard and Low-E glass. In addition to determining the temperature distribution, the system also calculates the glass surface area.

Both the infrared camera and the pyrometer are equipped with a digitally controlled optics protection system. These shutters significantly increase the maintenance intervals for cleaning the optics and completely eliminate the need for additional and time-consuming blowing of the optics with compressed air.

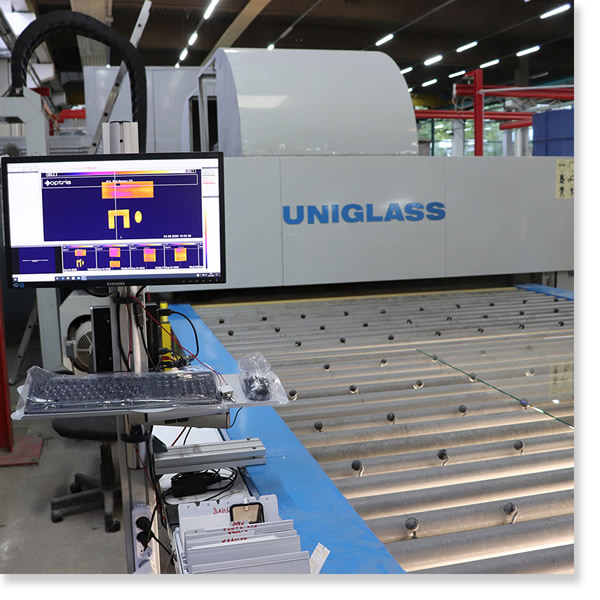

Optris supplies the Top Down GIS 640 R as a pre-assembled system for easy installation on glass tempering equipment. In addition to the infrared camera, pyrometer and the shutter systems, the delivery also includes a compact control cabinet with all electronic and control components as well as all necessary cables.

Compared to the line scanner systems often used in the past, the exact alignment of the scan line can be conveniently performed in the software with the camera-based GIS 640 R system - exact mechanical positioning of the system above the oven is not necessary here. The effort required for installation and commissioning is therefore reduced to a minimum.

Features

- Top down system with additional reference pyrometer from underneath for automatic emissivity correction on standard and Low-E glasses

- Digitally controlled lens protection system (DCLP) avoids extra air purging

- Glass area calculation

- Pre-assembled system for easy installation on glass tempering furnaces

- Automatic scan line adjustment – insensitive to distortions

Optris GmbH is a leading manufacturer of non-contact measuring equipment. Optris proposes both portable and fixed infrared thermometers for spot measurements as well as online infrared cameras for real-time thermography analysis.

600450

600450

Add new comment