Date: 24 March 2021

Active listening is the best service skill and helps to understand customer needs. It is an act involving attentive consideration of what the customer is asking, explaining or experiencing. And especially, it is a commitment built day by day, a consistent attitude resulting in new business opportunities.

With the above in mind, RCN SOLUTIONS is making efforts to improve on this challenging and delicate job.

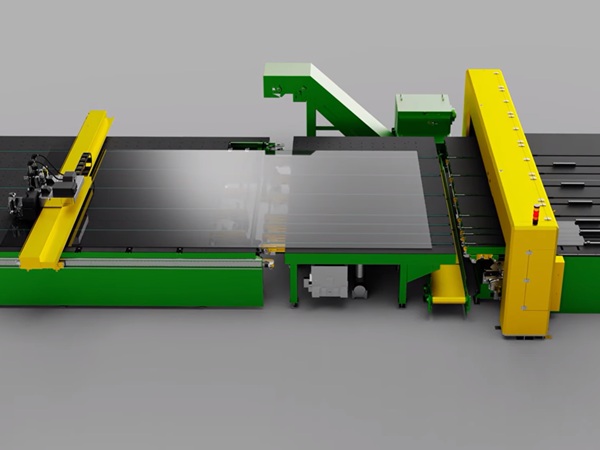

The company knows, thanks to the feedback from its customers, cleaning the glass edges after lamination is a major problem. The laminating interlayer squeezes out during the process and, since it cannot be removed hot, to clean cold it is a hard job, due to the particular specifications of the laminating interlayer, REVA BF, granting high adhesion and quality in safety glass.

Removing the exceeds is essentially a manual job by means of blades or other tools, but it requires time, and additional costs to the end product.

So the matter was how to solve this problem without interfering with the laminating process.

As a matter of fact, by using the “RD Clean Concept”, there is no need to adjust the pump aspiration values, with the risk of air bubbles. The RCN system allows keeping time and quality scheme unchanged, according to the RCN programs. At the same time, it does not force or involve the operator in changing parameters for any laminating run, going to adjust whatever during the operations.

So, RCN SOLUTIONS is proposing a unique possibility, a system granting the final product without troubling the production, without efforts, no extra finishing required, and most important no need for labor which means money saving.

However, the concept has another, not less important purpose: the UNI EN 12453-3 standard, concerning the dimensions and the finishing of the edges of the laminated glass, determines the tolerance of the thickness of the interlayer after lamination - tolerance that with the use of current bagging system, pressing strongly on the glass edges – can result, in some cases, lower than required, thus compromising the acceptance of the end product.

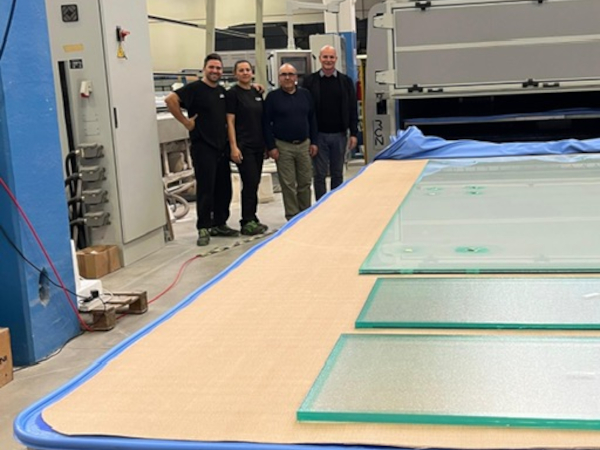

“RD Clean Concept”, developed by RCN, does not provoke any interlayer thickness reduction, thus assuring triple advantage: clean edges at the end of the process, perfect thickness of the interlayer after the process, and a money saving of about 40 percent of the labor costs.

The combination of service along with the RCN ability for development, has allowed design and production of a system to issue laminated glass that can be simplified by calling it “clean edges”, which embodies the idea there is no need to remove the exceeds of the laminating interlayer from the edges after the lamination.

Although the terms “clean edges” can sound familiar, the definitive, successful solution is by RCN only, and involves a technique specifically designed and tested.

This project, RCN is proud to say, was born from the mind of Davide Ricchi, junior partner of the company, who had the capacity and the tenacity to believe in this concept by researching, experimenting materials and testing continuously until the results have been the expected ones.

This new system is patent pending.

600450

600450

Add new comment