Date: 9 August 2021

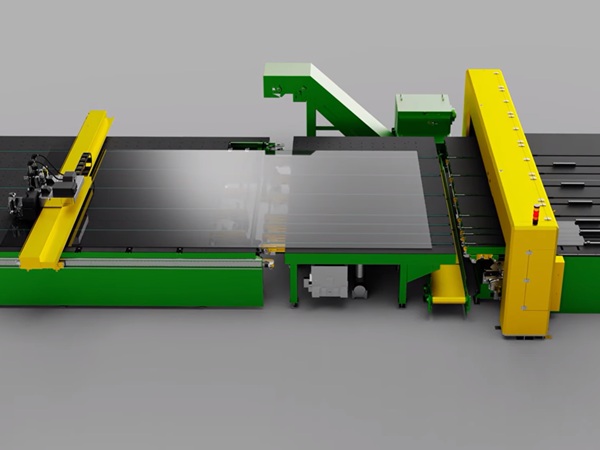

Every glass processor’s target is to simplify production while ensuring extremely stable yield and high end product quality. In this episode of the #AskGlaston Lamination Series, we wanted to demonstrate the capability of a modern glass lamination furnace featuring advanced convection technology designed to deliver just that.

Glass lamination is often considered a rather complex process. There are a huge amount of variables that you need to consider, starting from sandwich composition, glass coating, tempering quality, type of interlayer and more.

But what if we say that all the complexity of glass lamination is a thing of the past? A couple of quick test runs demonstrated in this video prove it well.

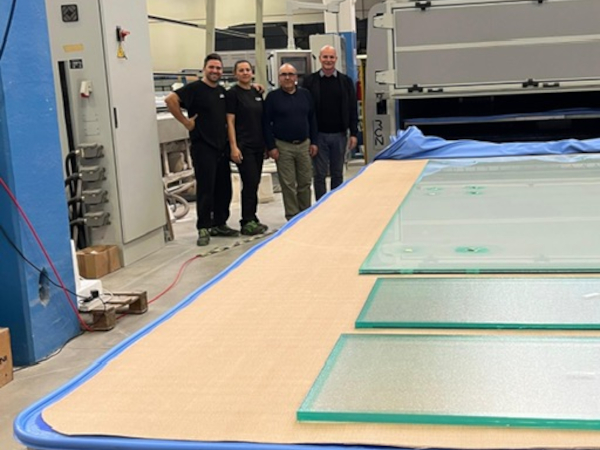

For a demo, the production scenario included running mixed production, switching from product to product.

In the first batch, 6+6 mm mixed production with clear and Low-E glass sandwiches is launched simultaneously. All are run with the same settings, which wouldn’t be possible with any other technology.

Next, without any changeover time, there is a switch to 5+5 mm triangle glass production. Again, no monotonous setting readjustment is done.

As to the quality for both batches, the appearance of the end products is flawless – and this with minimum operator input.

So how is all this actually possible?

The greatest thing about convection technology is that it doesn’t care about the glass coatings. It means the same heating efficiency for all glass types.

Meanwhile, due to a state-of-the-art and self-adjusting pressing system, the pressing force is also the same – regardless of the glass shape or size. And there is no need to adjust the settings of the pressing rolls.

Basically, all this allows mixing very complex batches in one loading. For the operators, it simplifies glass lamination extremely. The considerable part of the operator’s input that would normally be required is made unnecessary.

In the next episode, we will look into what is actually possible to achieve in glass lamination and see how far the limits can be pushed. We will also cover some new product releases. So, see you then.

600450

600450

Add new comment