Date: 12 August 2025

Author: Antti Lehtokannas | www.glastory.net

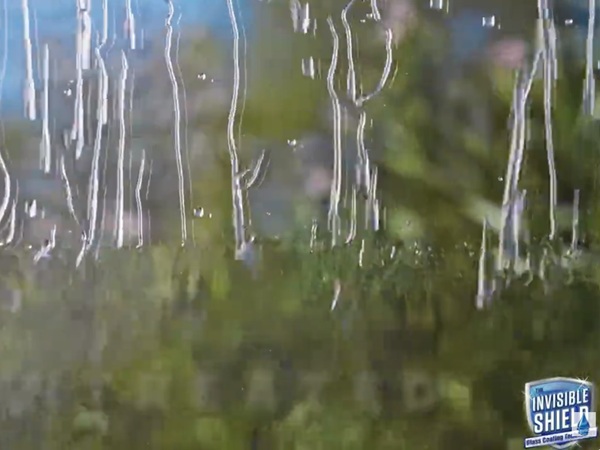

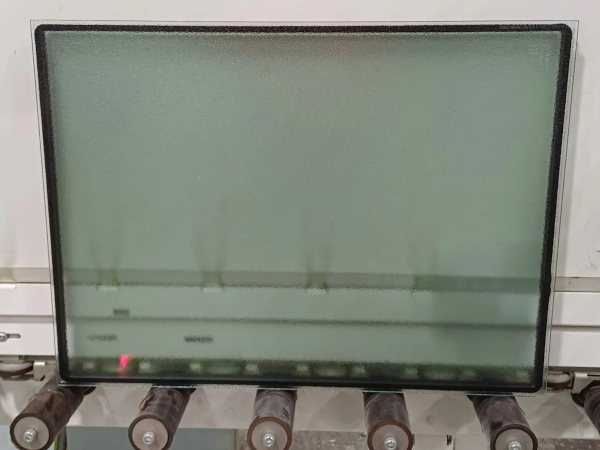

Tempered glass often shows visible patterns or streaks when viewed under polarized light. In practice, anisotropy can be visible, for example, as dark stripes or spots in windows. Typically, anisotropy becomes visible when the amount of polarized light is high, for example, during sunset.

This phenomenon, known as anisotropy, is caused by uneven heating and cooling during the tempering process, and it can compromise the visual quality of the glass.

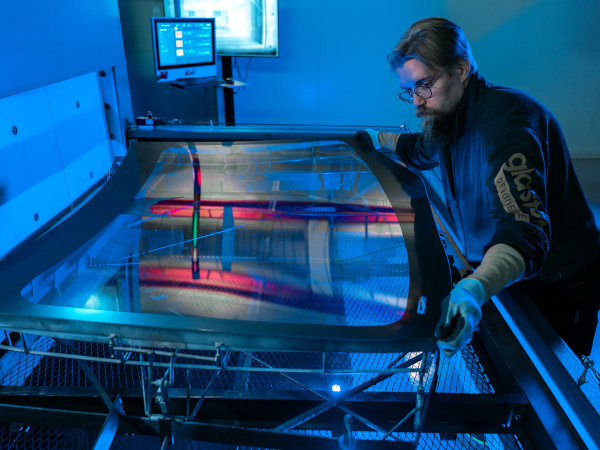

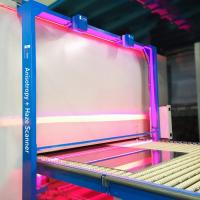

At Glaston, we’ve developed Anisotropy Control, an advanced solution designed to minimize these effects and improve optical clarity.

Anisotropy Control is based on revolutionary heating control and chiller nozzle cover design, ensuring optimal airflow across the glass surface. Anisotropy control can help to lower anisotropy levels by 50%, making anisotropy much less visible in the end product.

The result is clearer, more visually consistent glass — ideal for architectural and premium design applications where visual appearance is critical.

Whether you’re upgrading an existing line or investing in new technology, Anisotropy Control helps you deliver glass that looks as perfect as it performs.

600450

600450

Add new comment