Date: 4 March 2021

Remaining true to this principle, Nowak Glas has been building its reputation as a leading glass processing company in Germany. Their factory in Wattenscheid has a strong focus on isolating glass and a huge variety of all kinds of safety glasses.

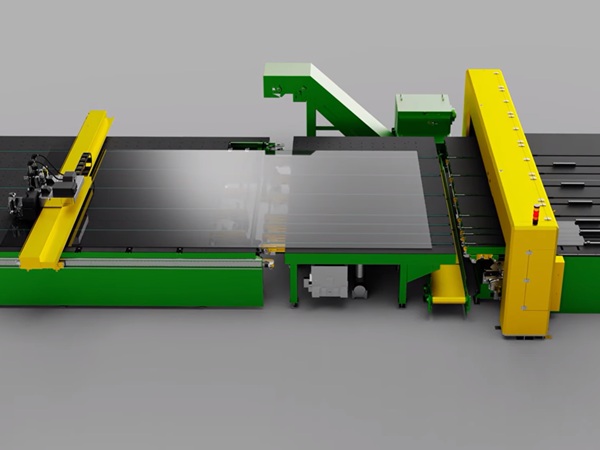

A horizontal Viprotron ECO Scanner System was installed to optimize their laminated glass production and keep high quality standards. Its compact size made a retro-fit installation in the existing Benteler-line very easy. Only two camera heads cover the width of 2,80 meters.

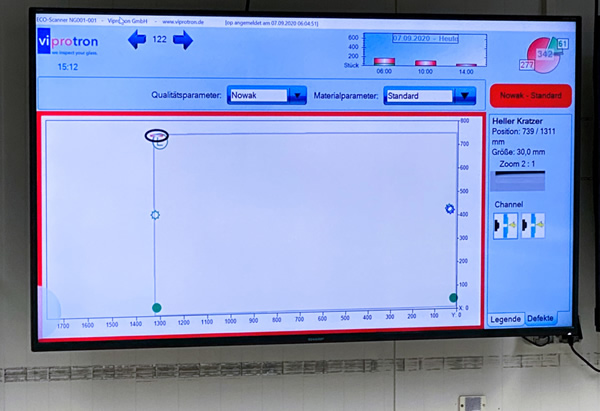

They were put into operation in summer and offered great results from the beginning. The Scanners inspect every single glass right after the washing machine for scratches, bubbles, dirt and fingerprints etc.. A large screen shows results and defect positions in real time. Defective panes are sorted out to make sure none of them are processed in laminated glass.

This ECO Scanner quality check assures a much better and reliable output than any visual inspection ever could. It is a great solution to save time and cost during the production process and to reach the best product quality possible.

600450

600450

Add new comment