Date: 9 April 2021

The order was received at the end of March and is booked in Glaston’s received orders for Q1/2021. The lines will be delivered within the next six months.

Larger glass panels in facades are a growing trend today. At the same time, safety and energy efficiency play an important role driving demand for tempered and laminated glass. StekloMir LLP is one of the largest enterprises in the Republic of Kazakhstan and they provide services related to glass cutting, processing, tempering, and painting.

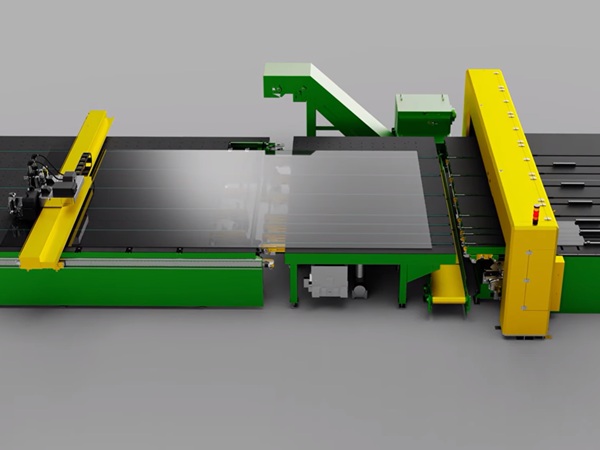

StekloMir has a large fleet of equipment for the production of a wide range of glass products, including automated lines with sealing robots for the production of insulating glass units (IGU) from former Bystronic glass which currently is part of Glaston. Yet they needed to increase their capacity for safety glass production in bigger sizes. With these two new Glaston glass processing lines, the customer can process glass up to the size of 3300x6000 mm with high performance.

The benefits that StekloMir was looking for are manyfold. The heating control in Glaston Jumbo Series flat tempering line ensures the energy-efficient production of high-performance end products. The ProL flat laminating line on the other hand utilizes Glaston’s convection heating technology that provides flexibility for laminated glass production.

“We are looking forward to a long and prosperous co-operation together with StekloMir. This agreement also strengthens Glaston’s position in the Kazakhstan market. Building a production line with these two major safety glass processes together indicates the trend in the market where tempering and laminating are closely linked with each other,” says Pekka Nieminen, VP Sales & Service, EMEA region.

“Quality, speed of production and innovation are our key priorities. We’re proud of the wide range of projects where we have been directly involved with our glass solutions. With Glaston technology and a strong services presence we can rely on high-end tempering capabilities and focus on developing and delivering high standard glass solutions to our customers,” says Vladimir Visotsky, Managing Director at StekloMir.

600450

600450

Add new comment