Date: 19 July 2018

A stunning example of a façade that gives building occupants nearly unobstructed views of the surrounding area, while delivering classleading structural and environmental performance.

Opening this year, the Shum Yip Upperhills mixed-use development − Class A Office & Luxury Hotel Complex − creates an imposing sight on the skyline of Shenzhen in China. The development features two towers, a ballroom pavilion and a large elevated pedestrian park with walkways that connect the site’s park with two of the city’s existing parks − Lotus Hill and Beacon Hill.

Image © SOM

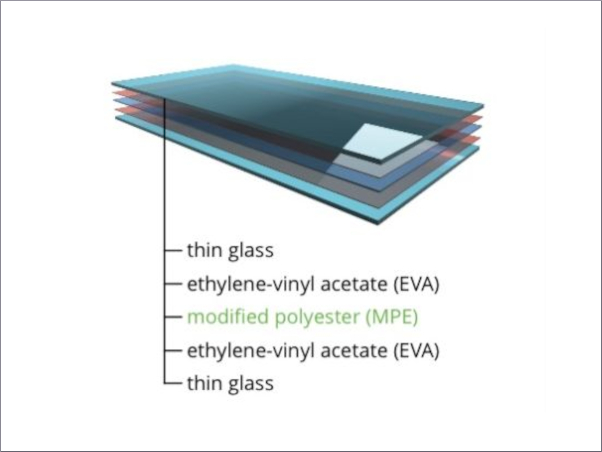

What is immediately obvious is the development’s application of glass, which enables to create an ultrasmooth skin on the skyscrapers thanks to a façade design that uses as few mullions as possible. The façade utilises insulating glass units made with a combination of heat-strengthened laminated and tempered glass.

The two towers − one an office tower measuring 290 m (950 ft) and the other, an office/hotel tower measuring 390 m (1,280 ft) − deploy over 150,000 m2 (1,614,586 ft2 ) of 1.52 mm (60 mil) SentryGlas® ionoplast interlayers from Trosifol™, in a variety of 3 m (9 ft) wide panel sizes. The insulating glass units consist of an outer lite of laminated glass made with two plies of 8 mm (0.315 in) heat-strengthened glass bonded together with a 1.52 mm SentryGlas® interlayer, a 12 mm (0.47 in) air space and an inner lite of 12 mm tempered glass.

According to architect Eric Van Epps, Director at Skidmore Owings Merrill’s New York office: “The whole building was designed to give occupants a view of the parklands and mountains within and surrounding the city. To enable these vistas, the horizontal glass modules used in the construction were oversized. Laminated glass was chosen for safety and insulating glass was specified to improve thermal performance.”

Image © SOM

“As the design architects, we made the decision to use a laminated construction,” he continues. “It is all about specifying glass that not only supports our vision, but also meets the desired performance of the building. As advisors to the client, we made recommendations as to the type of glazing that best suited the design requirements. The SentryGlas® interlayer was specified for this project because the laminated panels installed in the curtainwall were very large and the stiff ionoplast interlayer offered the design benefits we required.”

King Glass Engineering (KGE) Group, which specializes in the design, manufacture, installation and maintenance of structural glass and other light structure building systems, was the façade consultant on this project.

Image © SOM

Wang Zhongli, Design Manager at KGE, explains: “The glazing had to offer as much clarity as possible, while also delivering the necessary strength. We did look at other interlayer choices, but SentryGlas® not only offered better post-breakage performance, but it also delivered better rigidity and stiffness in temperatures up to 50 °C (122 °F). SentryGlas® also allowed us to reduce the overall weight of the panels and it contributed to maintaining the surface flatness of the heat-strengthened glass, which offers less distortion than fully tempered glass.”

Image © SOM

Before the build commenced, 200 m2 (2,150 ft2 ) façade mock ups were fabricated for both visual and performance testing, which is comprised of air, water and structural testing to local design codes − with the wind pressure rating being of particular importance due to the regions occasional typhoons.

SOM’s architecture and engineering teams also worked on the design of the hotel and the pedestrian bridges that span roadways, which together with the new elevated park, form a continuous tapestry of green that joins the two existing green spaces. In addition to the skyscrapers, SentryGlas® was also used on laminated glass railings around the site, once again for its safety capabilities.

This LEED Gold Pre-Certified (USGBC) design is a stunning example of an architect opting for a façade that allows the building’s occupants nearly unobstructed views of the surrounding area. As well as delivering excellent clarity, glass façades are also lighter than those made from a combination of masonry and ribbon windows.

But it is only the continual development of interlayer technologies by companies such as Trosifol™ that have made this approach possible.

As a result, with SentryGlas® eclipsing the performance of other architectural interlayers in many important areas, it is seeing a huge uptake across the globe in multiple applications for both new-build and refurbishment projects, due primarily to its strength, clarity, post-breakage performance, edge stability and its excellent long-term environmental capabilities.

Architects: Skidmore Owings Merrill

Façade consultant: King Glass Engineering (KGE) Group

Façade installers: Tower A (390 m/1,280 ft): Yuanda China

Tower B (290 m/950 ft): China Fangda Group Co., Ltd

Laminators: Tower A and Tower B: CSG Dongguan

Podium: Sanxin Glass

Podium Glass fin: Henan Zhongbo Boli

Building owner: Shenzhen Investment Co.

Trosifol™ is the global leader in PVB and ionoplast interlayers for laminated safety glass in the architectural segment. With the broadest product portfolio Trosifol™ offers outstanding solutions:

- Structural: Trosifol® Extra Stiff (ES) PVB and SentryGlas® ionoplast interlayer

- Acoustic: Trosifol® SC Monolayer and Multilayer for sound insulation

- UV Control: from full UV protection to natural UV transmission

- UltraClear: lowest Yellowness Index in industry

- Decorative & Design: black & white, colored & printed interlayers

600450

600450

Add new comment