Date: 17 January 2019

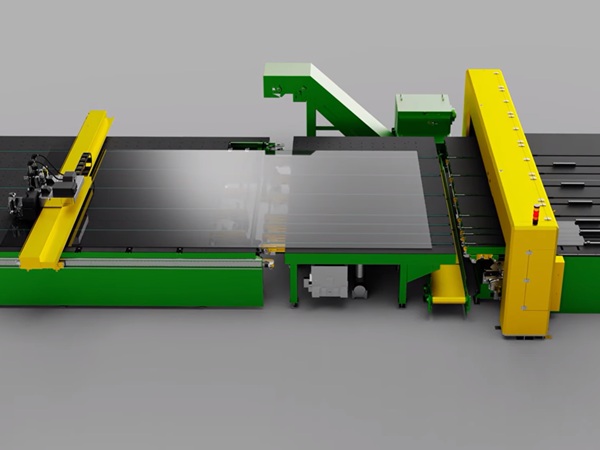

The new video of the Forel Coupling Press with Gas Filling - "No Limits" version - is online. For successfully process extra Jumbo size, the Coupling Press has been upgraded with many new features to ensure high processing quality.

For a uniform a filling, the machine has been equipped with an exclusive retractable suction cups system, also on the rear surface, to straighten any possible curvatures of big size laminated and/or tempered glasses.

The coupling press can process insulating glass units of up to 3 chambers, and it is also equipped with a double circuit for the gas emission: it can therefore use two different products for filling the chambers (argon/krypton). The gas filling system is self-adjusting and can regulate the emission along the glass length, optimizing wastes.

The Art. APG - NL is also capable of pressing stepped units with up to 1000 mm of horizontal offset and 250 mm of vertical offset, thanks to the continuous bottom support assured by the independent conveyor belts with load capacity of up to 350 kg by linear meter.

The "No Limits" IG Lines range by Forel is the new solution developed for processing insulated panes up to 15 meters of length, following the usual standards of precision and reliability of Forel machinery.

Look at the Art. APG- NL into operation:

600450

600450

Add new comment