Date: 1 February 2024

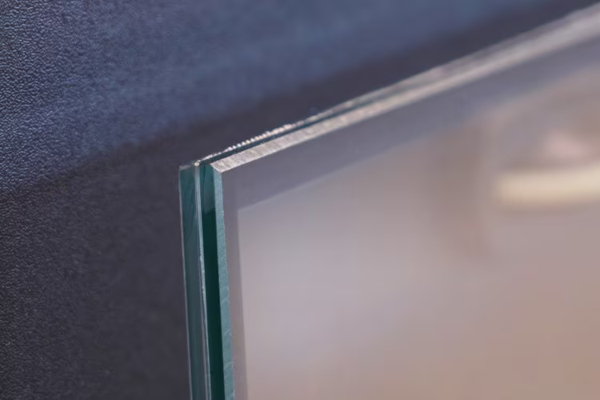

These technological solutions have been specifically developed to process the edges of float, laminated and low-e glass, with square or rectangular shapes.

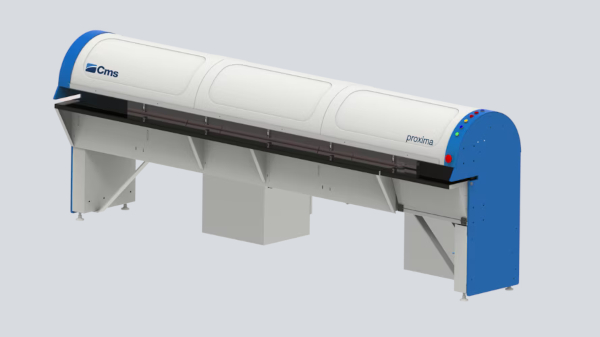

Aura and proxima are CMS automatic seaming machines designed and developed for dry seaming, specifically with no water needed. They have been designed to satisfy customers' needs in terms of ease of use, rapid installation, reliability and low management costs.

KEY BUYER BENEFITS:

- No need for water [COST SAVINGS]

- 100% automatic handling of different thicknesses [PRODUCTIVITY]

- Complete collection of machining dust [SAFE WORK]

Aura is the CMS vertical dry seaming machine, it can be used as a stand-alone machine, it can be perfectly connected to a washer and it's the perfect fit for an insulated glazing production because it is suitable to work on 3 shifts. The operator loads the glass and starts the processing cycle, the machine automatically measures the incoming glass (height, length and thickness) and machines the edge. Aura also adapts its operating units to different thicknesses.

Proxima is the CMS automatic horizontal seaming machine, and it is the ideal solution for all small-medium glass factories that need to venture into seaming with a modest investment. This machine has been conceived to be combined with both tilting float glass cutting tables and laminated glass cutting tables. CMS proxima allows to machine the edge of the glass just after cutting before removing it from the table, thereby avoiding the need to handle it twice.

600450

600450

Add new comment