Date: 16 August 2021

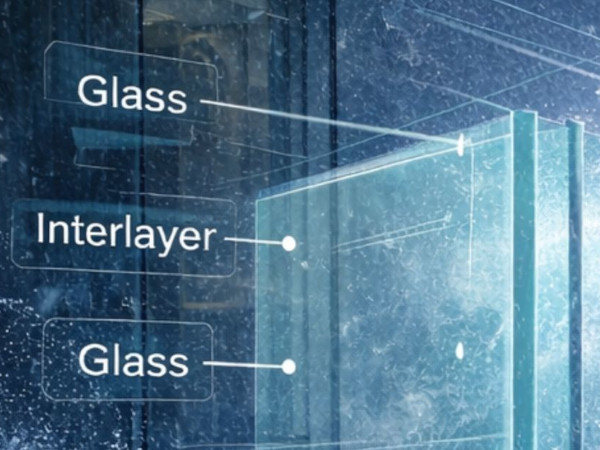

One of the most common trends of the laminated glass market is the growing complexity of the end products. Though the complexity is increasing the performance of the laminates, it is also posing some new challenges to the glass lamination process and equipment.

One of the most common issues you can see on a complex laminated glass is a trapped air problem all over the laminate. We have seen this issue many times – both with old and new technologies.

Finally, we were able to understand the reason for this kind of glass behavior. What is more, we have tried to provide the solution to the problem and developed the newest convection technology specifically to tackle this issue.

To showcase the capabilities of the new system, the glass type that is run in a video is three times 10 mm with two SentryGlas® films in between each glass. The result speaks for itself.

For the glass processor, using the solution like this means being able to produce very challenging multi-layer laminates with high capacity and high yield – all while keeping the high level of end product quality.

Being now under development in Finland, the new technology will be launched soon. Importantly, the existing users of the ProL technology will also be able to upgrade their laminating lines with the new convection system.

In the next episode, we will be discussing the upgrade possibilities for the glass lamination lines and cover the ways of improving the yield of any existing line.

BY JUSSI NIEMIOJA

600450

600450

Add new comment