The Würth House with education and training center is being constructed in Rorschach on the shores of Lake Constance in Eastern Switzerland. The architecture blends into the existing surroundings and landscape while maintaining a distinctive identity of its own. The building encased in two layers of glass whose appearance shimmers between transparency and reflection.

Fabric presentation

Würth House

Rorschach, Switzerland

«Suurstoffi»

SEFAR® Architecture VISION

Used fabric AL 140/70

Architects: Annette Gigon / Mike Guyer, Zurich, Switzerland, www.gigon-guyer.ch

.jpg)

.jpg)

Suurstoffi (Means oxygen in local dialect) - Rotkreuz, Switzerland

SEFAR® Architecture VISION

Used fabric AL 140/70, printed

A large development is being built in the central Swiss town of Rotkreuz, which when finished will include homes, offices, and a villagelike infrastructure. The first phase of construction has resulted in apartments for rental, 9000 m2 of office space, and 3000 m2 of service areas. The Novartis Corporation Headquarters building is fitted with aluminium coated VISION Fabrics, printed in four separate colors.

Architect

Holzer Kobler Architects, Zurich, Switzerland, www.holzerkobler.ch

.jpg)

.jpg)

General Information Transmission, Lamination and the VISION Effect

SEFAR® Architecture VISION

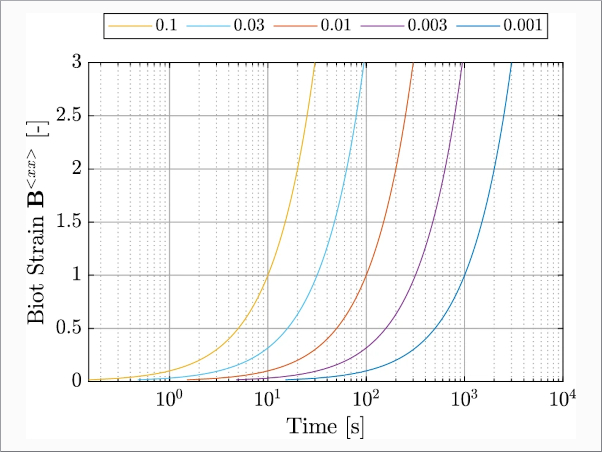

The yarn thickness is either 140 or 260 μm depending on the fabric type. The basic product range consists of five fabrics with a mesh opening of between 25 % and 70 %.

Vision fabrics are coated with metals by means of a sophisticated process. The metals used are aluminum, copper, chromium, titanium and gold, as well as printed copper and gold. One-sided metallic coating is used exclusively in the basic product range. The reverse side of the fabric is in black color.

On request, both sides of the Vision fabric can be coated. It is even possible to have different metallic coatings on the front and reverse sides of the fabric.

An example of transmission values, tested at «Empa» (Swiss Federal Materials Testing Center) on AL 140/70 unprinted in 2 x 4 mm low iron glass.

G-value: 61.6 %

LT-value: 61.8 %

The VISION effect

From outside, the fabric keeps prying eyes away – from inside the view remains free.

On distance, a slight doubling effect arises.

Optional printing on VISION Glass lamination of VISION fabrics

.jpg)

View from outside View from inside

.jpg)