This paper was first presented at GPD 2025.

Link to the full GPD 2025 conference book: GPD_2025_ConferenceProceedingsBook.pdf

Author: Julia Schimmelpenningh

Eastman, United States of America

Abstract

Modern façade glass elements need to meet high and repeatable standards of security performance, as well as being acceptable for human physical and psychological comfort. New standards and philosophies on protective glazing have emerged with the publication of two very significant international standards involving ballistic assault. Those standards and laminated glass configurations or design methodologies will be explored. This paper will outline the significant portions of those standards that influence glazing selection and examine how these performance characteristics are able to be multifunctional to meet other requirements such as safety, acoustic, solar, thermal and structural with style.

Article Information

- Published by Glass Performance Days, on behalf of the author(s)

- Published as part of the Glass Performance Days Conference Proceedings, June 2025

- Editors: Jan Belis, Christian Louter & Marko Mökkönen

- This work is licensed under a Creative Commons Attribution 4.0 International (CC BY 4.0) license.

- Copyright © 2025 with the author(s)

1.Introduction

Modern façade glass elements need to meet high and repeatable standards of security performance, as well as being acceptable for human physical and psychological comfort. The trend toward using more glass in building design has created opportunities to design for enhanced performance in many areas, but a concentration on safety and security are the current focus area for this document. New standards and philosophies on protective glazing have emerged with the publication of two very significant international standards involving ballistic assault.

Laminated glass, two or more pieces of glass held together by an interlayer, has long been used as an enhanced safety glazing. The enhancement comes from the capability of holding the broken glass shards together by the interlayer versus shattering into thousands of falling or flying pieces, while still reducing cutting and piercing injuries.

Certain configurations, based on safety glazing concepts with known and proven interlayers are also being designed for applications warranting enhanced protective capabilities in security applications. These glass units tend to have more penetration resistance capability than basic laminated safety glass and can range in performance from simple impact to multi-assault resistant glazing.

Ordinary glass windows, doors, balustrades and skylights can result in serious injuries when broken, causing dangerous flying, or falling shards or pieces. In cases where this is a concern, special precautions against injury and property loss must be considered. Unlike monolithic glass, however, laminated glazing for interior and exterior glazing, made with PVB and PVB composite interlayers in clear or colors reduce the risk of injury because glass tends to adhere to the interlayer after impact— this ability for the laminate to break but stay essentially intact also adds to protecting the integrity of the building envelope, providing the needed post breakage integrity, and most importantly providing protection to people and property.

Of course, glass can always be broken by accidental or natural causes. However, today’s building and construction professional must also consider protection against manufactured threats, such as forcedentry and forced-exit, ballistics, and blasts—whether caused by nefarious sources or combustible industrial materials during production or transfer.

While no single product offers complete protection from intentional attacks, laminated glass with Saflex PVB interlayers in properly designed systems can be a critical line of defence in the overall security plan. These strong protective interlayers act to deter or delay attackers from gaining entry while protecting people and property from injury and damage. In recent years, interest has grown rapidly in the continued use of glazing to allow all the benefits of natural light to penetrate deeply into the building, while incorporating the protective benefits of security. Buildings especially noted for making these considerations a top priority tend to be categorized as educational (Primary through Higher education), industrial, government and commercial building applications. Residential applications can also incorporate security glazing system but are typically designed with specific and individualized protections targeted.

2. Test Protocol for ASTM F3561

Eastman has completed testing on various Saflex interlayer combinations in accordance with most of the security standards related to glazing that are published by ASTM International (hereafter “ASTM”). The results indicate that the increase in interlayer thickness between two layers of glass will tend to increase the resistance to penetration from repetitive blunt tool impact, while multiple layers of glass and interlayers, or glass, interlayers and plastics are needed for high velocity missile deterrence such as ballistics. It has also been determined that PVB composite interlayers perform to the same or higher level of penetration resistance typically at a thinner overall construction versus conventional PVB configurations.

The most recent international security glazing standard to be published is ASTM F3561, Standard Test Method for Forced-Entry-Resistance of Fenestration Systems After Simulated Active Shooter Attack. In this severe test, the glass is systematically broken and then impacted until capability to obtain entry is achieved. Although bullets are used (or may be simulated in the glass-only evaluation), ASTM F3561 is a forced entry resistance standard meant to deter entry of an assailant that potentially has the intent of further injury or damage after entry.

This method is meant to simulate opening generation for reach-for-release, or full walk-through entry. In reach-for-release attempts, an opening only needs to be big enough to allow a gloved hand to fit through with little force, thus the 152 mm opening, to release a latched opening in a door or window. In full walk-through conditions, the glass typically vacates the frame creating an opening for full body passage. The test method is written for full system testing, meaning testing glass, plastics or panels that are glazed into a window, door or other fenestration system. It is not meant to certify a glazing for replacement infills. There is an appendix to this standard that allows infill materials to be tested, but only as a predictor for the glass component. The result of this glass-only testing is what are described in the information below.

These tests have been performed on laminated glass configurations only. They have been set into the frame which is specified in the standard. The glazing tested have been primarily conducted on laminates made with glass plies that are 3 mm thick, annealed, and the glass dimensions 61 cm x 61 cm. This glass type and thickness was chosen to understand the contribution of the interlayer to the penetration performance and pass/fail requirements of this test method and is not a limitation to the configurations which can be used in actual system testing and evaluations.

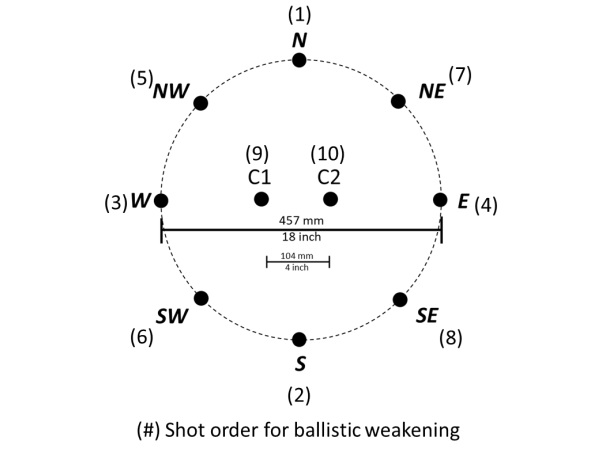

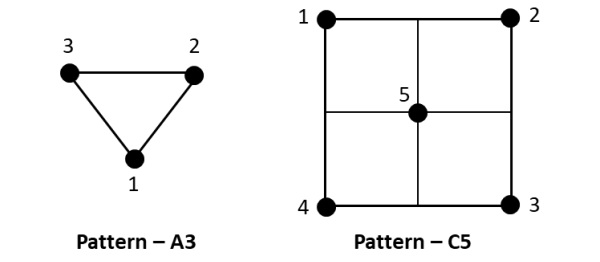

The glazing evaluation portion of ASTM F3561 test method consists of firing 10 bullets at the glass in a specified order and pattern (Figure 1) with the intention of gaining entry or weakening the glass. For glazing that is not enhanced, this portion of the test will typically cause enough breakage or shattering that reach-and-release or walk-through can be obtained.

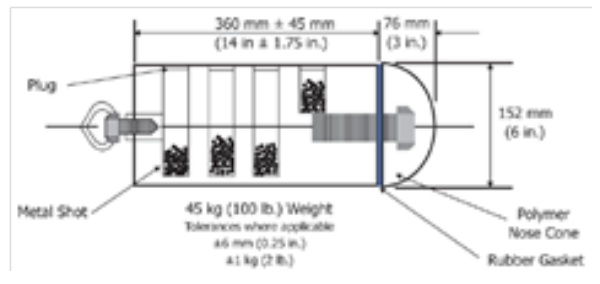

With two ply laminated glass configurations containing PVB or PVB composite interlayers, the bullets typically go through the glass leaving small holes between 1 – 8 mm in diameter. These holes are surrounded by a tight web like glass breaking pattern with a few radiating glass breaking streams from each entry location. The laminate is checked after each shot to evaluate the ability to pass an arm through for the potential of unlocking a window or door for entry, as this would be a failure. The opening size is checked with a 152 mm solid sphere. If no entry is gained after any or all the shots from ballistic weakening, the laminate is then subjected to impact from a 45 kg impactor (Figure 2) with a rounded nose cone.

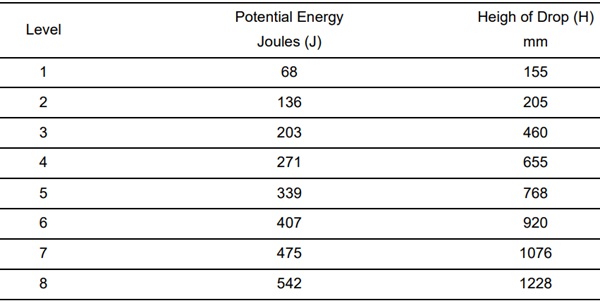

The impact is used to simulate blunt impact after the glass has been weakened in as an additive attempt to gain entry. The drop height for Level 1 qualification starts with the bottommost part of impactor nose at 15 cm above the center of the glass, two drops from the same height are required for each level. All evaluations begin at level 1 and proceed through the desired level of performance, failure, or the completion of Level 8, whichever comes first. The drop height increases by 15 cm after each pair of drops are deemed to pass. The impactor is adjusted upwards for each progressing level of protection after two successful impacts; however, the evaluation of the specimen is done after every impact. There are a total of 8 performance levels with each level requiring two impacts, therefore it takes 16 impacts with the impactor on the same, pre-weakened glazing in the same spot of the laminate to pass level 8, 14 impacts for level 7, 12 impacts for level 6 and so on. See Table 1 for drop heights and impact energy.

Table 1: Impactor drop heights and energy.

3. Test Results for ASTM F3561 Glass-Only

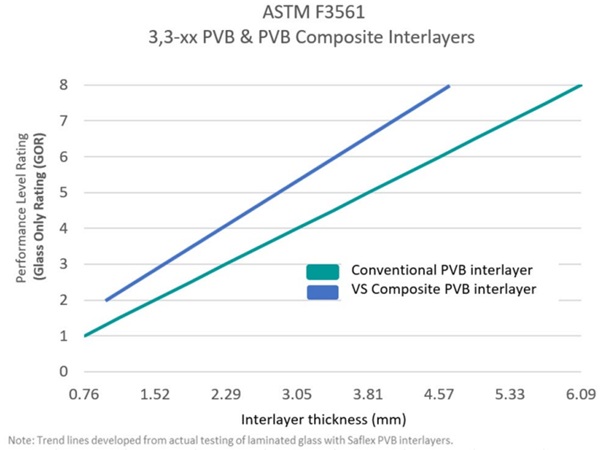

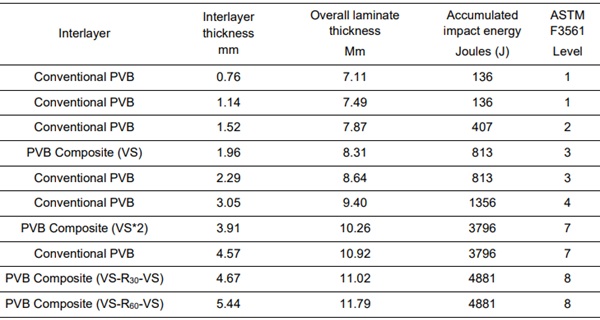

The glazing configurations needed for these types of attacks vary with the protection level desired but typically start with 0.76 mm PVB interlayer and increase in interlayer thickness for higher levels. Alternately the levels are achieved using a composite PVB interlayer type (Saflex VS) which typically requires a thinner overall construction to meet the same level as layered conventional PVB. VS PVB composite interlayers as tested were able to be used as thinner overall interlayers (14-38% interlayer thickness reduction depending upon the level) allowing the glazing to reach similar or higher performance levels than those with conventional PVB interlayers.

In general, the glass only tests indicate that each additional layer of the 0.76 mm conventional PVB interlayer tested is needed for each level increase. For example, a level 3 laminate would need 3 layers of 0.76 mm or 2.29 mm PVB interlayer between two plies of 3 mm annealed glass. In limited testing, it was determined that tri-layer acoustic PVB, PVB interlayers with markers embedded for bird deterrence, semi-rigid PVB and PVB with colorants or other performance additives for solar control all perform similarly to the homogenous PVB interlayer tested.

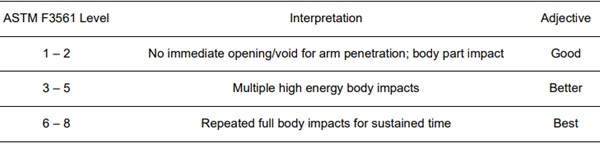

PVB composite interlayers, an interlayer with PVB skins and an encapsulated film, have been demonstrated to achieve a level higher in ASTM F3561 glass only ratings than the comparative conventional PVB. Table 2 provides an interpretation and grouping of the various levels outlined in the standard as they relate to attack. Table 3 provides glazing system details, and their performance levels based on glass only ratings on laminates with 3 mm annealed glass plies.

Additional studies were conducted which examined the effect of glass thickness and glass strengthening on performance levels attained in the glass only testing. The glass thickness change from 3 mm up through 8 mm did not change the final performance level for the glass-only samples as tested. The only significant difference was the increase in the amount of cohesive failure of the glass and glass particulates falling from the specimen during testing as the glass thickness increased. The heat-strengthening or fully tempering of the glass did elevate the performance of the conventional PVB interlayers by 1 level of performance on average. It should be noted that only 5 mm glass was evaluated in the strengthening study since the glass thickness did not affect performance as seen in the earlier study.

In a pilot evaluation, double laminated IGU systems were tested. These double laminated systems performed to the same level as the single laminated unit having the same total amount of interlayer. For example, a double laminated insulating unit of single laminated unit configuration of 3 mm annealed glass |1.91 mm composite PVB interlayer| 3 mm annealed glass [12 mm air space] 3 mm annealed glass |1.91 mm composite PVB interlayer| 3 mm annealed glass (3,3-3.91 cPVB [12] (3,3-3.91 cPVB), performed at Level 6 glass-only impact, just as 3 mm annealed glass |3.91 mm composite PVB interlayer| 3 mm annealed glass (3,3-3.91 cPVB) did. This indicates that the total amount of interlayer in the glazing system is the major controlling factor for performance versus the glass. This provides flexibility in the glazing configurations which can be incorporated into the façade or glazing systems design and may make laminate production simpler by requiring less layers between two pieces of glass.

Table 2: Laminated Glass Configuration Interpretation.

Table 3: Laminated Glass Configuration and Glass Only Rating (GOR) Levels.

The glass only test of ASTM F3561 allows for two methods of glazing evaluation. The first is the actual firing of ballistic ammunition through the glazing, known as Method A and is the method used to generate the previously discussed results. Method B consists of drilling 6 mm holes through the laminated glass in the same pattern as used in the ballistic firing. As the drilling does not generate the same crack pattern as the ballistic shot, an initial impact from 152 mm drop height is required before the qualifying impacts begin. Based on testing completed on laminated glass configurations prepared at the same time, Method A and Method B give similar responses with Method B being more severe in some cases by a half step, or falling one impact short of Method A.

4. Ballistic resistant testing – ASTM F3279

The other newly published security standard through ASTM is F3279, Standard Test Method for Ballistic-Resistant Security Glazing Materials. This document specifies the testing procedures for evaluating the ballistic resistance of security glazing materials. Two major differences between this and the previous standard discussed are, 1. Testing of glazing alone for qualification is allowed, and 2. The bullets are allowed to penetrate the glazing, but spall and bullet fragments are rated based on witness panel assessment.

4.1. Purpose and Scope of ASTM F3279

The standard provides protocols for assessing the resistance of security glazing materials against ballistic threats from various weapons and ammunition. The assignment of ratings is also described with the introduction of new terms such as Ballistic Resistance Class (BRC) and Ballistic Test Identity (BTI). ASTM F3279 is also the only known ballistic resistant standard to require different size specimens for various shot patterns, provide options for test temperature based on intended use and provide performance ratings to satisfy risk, threat and vulnerability assessments that separate life safety and ocular safety in the evaluation of ballistic glazing.

4.2. Test Methodology Summary of ASTM F3279

Ballistic Resistance Class (BRC) relates to the amount and severity of spall that comes off the glazing after testing. BRC is determined based on the witness panel selected and the amount of damage. No perforation formed by spall in the witness material may be greater than 3 mm in length or width when measured. The spacing from the specimen (15.2 cm) is the same for either type of witness panel. The witness panels are aluminum sheeting with two thickness options 0.051 mm and 0.51 mm. The thinner witness panel (0.051mm) being used to determine those glazing units typically termed “no spall”. This witness panel is designated with the character “O”, signifying the resistance to ocular injury. The thicker witness panel (0.51 mm) option is to ensure no spall of significant size is ejected from the witness side of the glazing unit at a velocity that typically would have potential to cause a life-threatening situation, thus designated as “L”. It is important to note that the bullet fragments are considered in the spall/nospall rating.

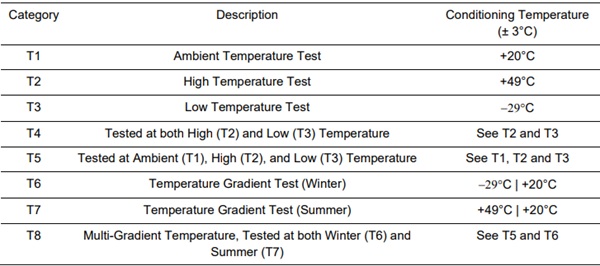

Test temperatures set points are cold (-29°C), ambient (20°C), and hot (49°C), they are designated T1 through T8 depending upon how they are applied (see Table 4).

There are four basic shot patterns outlined in the standard, with the separation of the shot difference contributing to the 6 total shot options available. The typical triangular shot pattern is included, but patterns range from a single shot through a zig zag 8 shot pattern (see Fig. 4).

Table 4: Temperature options for ASTM F3279.

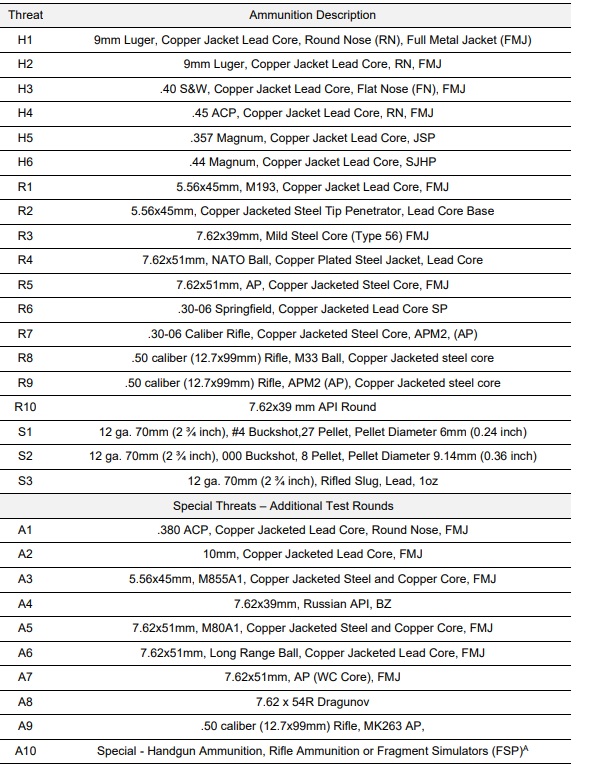

The weapon and ammunition combinations allowed within the standard are also expanded to cover the majority of “commonly known” firing mechanisms. There are 29 threats designated which cover various handgun, rifle and automatic weapon/ammunition combinations. However, 9 threats commonly called out in the industry classifications have been specifically designated in the body of the standard for ease of specification.

Table 5: Select information from threat designations of ASTM F3279.

4.3. Classification Rating for ASTM F3279

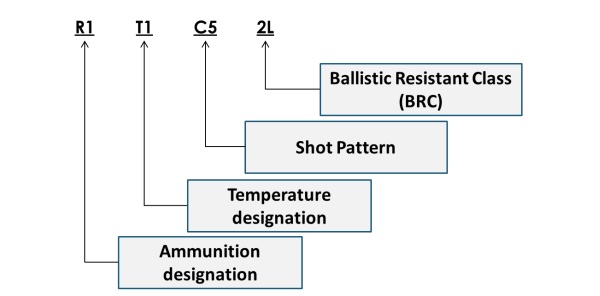

Due to the flexibility and expansion of options in the ASTM F3279 standard, a mechanism to identify and specify these ballistic performances is included and designated as the Ballistic Test Identity (BTI). This is the defining category for performance. It consists of concatenating abbreviations from the test characteristics: threat, temperature, shot code and witness panel, into a 4-section code consisting of 8 characters. For instance a BTI of R1-T1-C5-2L indicates a bullet resistant glazing which has passed the requirements of a rifle firing a M193 bullet (R1) has been used, the laminate was tested at ambient condition (T1), there were 5 shots fired in a square plus center pattern (C5) and the evaluation of materials ejected from the back was against the thicker witness panel criterion (2L) allowing what is deemed as non-life-threatening spall.

It is expected that the addition of the spall/no spall, plus the options in the shot patterns and temperature evaluation will allow greater flexibility in assigning the proper glazing configuration based on the threat, risk and vulnerability of a facility while potentially keeping costs in line with the needs versus over-specifying performance. The designation of the 9 industry levels are meant to help the laminators in the basic number of configurations needed to engineer, qualify and market ballistic resistant glazing and keep the number of options in-line with historical standards.

Laminated glass configurations tend to be proprietary to the fabricator. The use of conventional PVB interlayers has been incorporated into ballistic resist glazing for decades. Like ASTM F3561 forced entry testing, the use of PVB composite interlayers has also shown benefits in reducing the amount of conventional PVB thickness needed to reach specific levels. More studies with detailed analysis are planned to further define these benefits.

5. Summary

To achieve appropriate protection, the selection of glass, glazing details and framing system are as important as the performance of the glass in delivering the security protection levels identified. Specific risks, threats, vulnerabilities, facility design and building orientation are aspects of security that also need to be considered. The modern security standards that have been published by ASTM consider aspects evidenced in society that need to be addressed and accounted for.

Laminated glass options with PVB interlayers and composite PVB interlayers are capable of being assembled to meet many if not all these testing requirements and deliver the various categories of protection outlined. The durability of these glass configurations also help maintain the consistency of performance after installation without the potential of degradation from everyday wear and tear such as rubbing against it, scratching and cleaning. They provide visibility and other unseen performance characteristics such as UV screening and sound abatement. Laminated glass with PVB based interlayers can be combined with other compatible PVB layers for other multifunctional characteristics including color, structural and solar and energy control, therefore conventional PVB interlayers and PVB composite interlayers are an excellent choice for ASTM F 3561 and ASTM F3279 security glazing.

Acknowledgements

The author would like to acknowledgement the National Glass Association (NGA) for the initiative in forming the working group which identified the gaps in security glazing specifications, especially for schools which lead to the development of ASTM F3561. Also, Intertek Testing Laboratory in York, PA, through Mr. Travis Hoover for quickly bringing this test on-line for the benefit of the industry. ASTM International committee F12 members and staff for driving these documents through hours of discussions, debate and revisions to reach consensus. Lastly, Eastman for the support, recognizing the importance and need and allow the time needed to devote to leading these documents through publication and subsequent revisions.

References

ASTM F3279-24, Standard Test Method for Ballistic-Resistant Security Glazing Materials, ASTM International, 100 Bar Harbor Drive, West Conshohocken PA, USA, www.astm.org

ASTM F3561-23, Standard Test Method for Forced-Entry-Resistance of Fenestration Systems After Simulated Active Shooter Attack, ASTM International, 100 Bar Harbor Drive, West Conshohocken PA, USA, www.astm.org

Saflex™ and Vanceva™ Security Glazing meeting ASTM F3561 1 “Active Shooter” – Eastman Chemical Company, November 25, 2024, www.saflex.com

School Security Glazing (FB71-24), National Glass Association, 344 Maple Ave West Unit 272 Vienna, VA, USA, www.glass.org