Date: 13 October 2021

Stunning spiral design balances amazing mountain vista with the demands of snow-based physics, creating the perfect monument to watchmakers.

Located Le Brassus, in the Jura mountains, about an hour north of Geneva in Switzerland, the Musée Atelier is an architectural homage to the skill, intricacy and sweeping shapes associated with the fine art of watchmaking.

Photo: Courtesy of Audemars Piguet © Iwan Baan

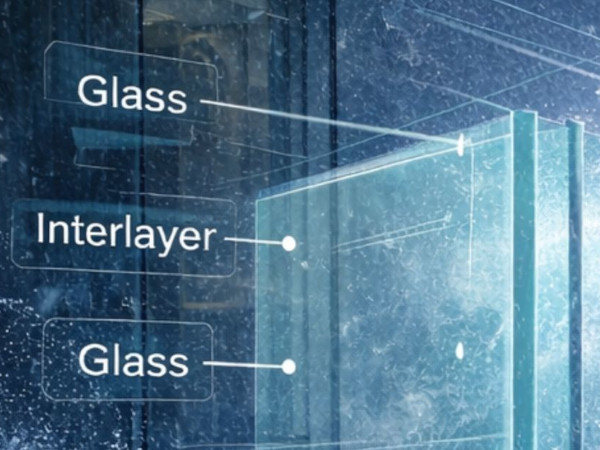

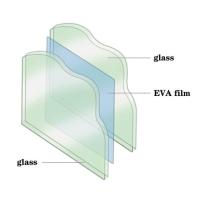

The building – the result of an architecture and museography competition launched in 2013 – is located on a site which Audemars Piguet has occupied since 1875. Taking seven years to develop and now complete, it is a staggering example of architecture, meets nature, meets watchmaking and has laminated safety glass – using SentryGlas® ionoplast interlayers from Kuraray – to thank for supporting and enabling its stunning shape, form and function.

Jasmine Audemars, Chairwoman of the Board of Directors, explains: “The Musée Atelier Audemars Piguet pays tribute to the watchmakers and craftspeople who have made what Audemars Piguet is today, generation after generation. This living museum was born from a desire to present our craftsmanship and legacy in a building that reflects both our deep-rooted origins and our forward-thinking spirit.”

When viewed from above, the structure – the first of its kind to be built at such altitude – resembles a watch spring and comprises two interlocking spirals, separated by glazed panels, looping around a common centre. They are differentiated from each other when viewed from the side by their varying roof heights; instilling the building with an almost oscillating spiral waveform too.

Photo: Courtesy of Audemars Piguet © Iwan Baan

Danish architecture firm BIG (Bjarke Ingels Group) pushed the envelope of design with this spiral-shaped pavilion by having the living roof entirely supported by curved laminated-glass interior and exterior panels – complementing the design of the founders’ house and the first workshops where Jules Louis Audemars and Edward Auguste Piguet established their company in 1875.

“Watchmaking, like architecture, is the art and science of invigorating inanimate matter with intelligence, performance, movement and measure; to bring it to life in the form of telling time,” explains Bjarke Ingels, BIG Founder and Creative Director.

Philippe Willareth from Lüchinger+Meyer, the structural and façade engineers tells us: “This project touches some important topics: Firstly, equilibrium. Structurally we had to balance the steel roof with the 140 glass elements to create a robust construction; and the other important aspect was energy use, so the energy efficiency of the materials was just as important as the structural calculations.

“Structurally, we also had to consider the microclimate of the region,” explains Willareth. “At 1,000 m altitude, it’s one of the coldest areas of Switzerland and can have a lot of snow, which also presents problem between seasons when it gets wet, so snow loading was an essential part of any calculations. Indeed, in some areas we had to expect a tonne of snow per square metre. The resulting design fulfils the latest Swiss Minergie requirements in terms of energy efficiency and its high-quality construction.”

The load-bearing curved glass panels are triple glazed and are affixed using structural silicone to geometrically bed them into steel shoes, as opposed to point fixings, which create stress points. Surface quality was another important element of the design, so the designers had to use a glass that was as transparent as possible.

Mock-up modules were also created, with various panel types, not only to show the client the glass quality, but also to prove the load-bearing principals of the glass design. These modules were also used to experiment with various coatings and to study their effects on energy transmission. Once finalised, the panel formulation underwent a variety of test at the Façade and Metal Engineering Center at Lucerne University, where their load-bearing capacity and structural capabilities were measured and verified.

The final formulation of insulated glass units chosen for the external supporting walls comprises (inside out) three 12 mm annealed ultra-clear glass panels laminated with two SentryGlas® interlayers + 16 mm argon-filled gap + 8 mm glass + 16 mm argon-filled gap + two 8 mm glass panels with a SentryGlas® interlayer between them. The internal panels are made up of three 12 mm annealed ultra-clear glass panels laminated with two SentryGlas® interlayers.

According to Audemars Piguet: “This architectural combination symbolises the blend of tradition and innovation at the heart of our craftsmanship while honouring our deep-rooted origins. BIG’s elegant spiral, seamlessly rising from the ground, offers a pristine setting for our masterpieces of complication and avant-garde design which have taken shape, year after year, in this remote valley of the Swiss Jura Mountains.

A white paper produced to discuss this project explains: “It all started with that idea of a full glass building in the competition. Back then, nobody on the project team knew if this would be possible. There were of course some reference projects with load-bearing glass already built, but probably none of them had to deal with so many different requirements.”

As is the case with many demanding engineering and architectural challenges, when the aesthetics of glass has to be balanced with functionality and strength, the first item on the list is SentryGlas®. Unrivalled in its performance, longevity, clarity and post-breakage capabilities, SentryGlas® is the bedrock of so many architectural projects, from masterpieces such as the Musée Atelier to hurricane-strengthened residential and commercial/ municipal buildings on the coast of America.

Architect: BIG Bjarke Ingels Group, New York

Local architect: CCHE, Lausanne

Façade and structural engineering: Lüchinger+Meyer, Zürich

Specialist façade contractor: Frener & Reifer, Brixen (Neulichedl & Partner)

Glass Processor: SFL Glastechnik, Stallhofen

Building Owner: Audemars Piguet, Le Brassus

Kuraray is the global leader in PVB and ionoplast interlayers for laminated safety glass in the architectural segment. With the broadest product portfolio Kuraray offers outstanding solutions:

- Structural: Trosifol® Extra Stiff PVB and SentryGlas® ionoplast interlayer

- Acoustic: Trosifol® SC Monolayer and Multilayer for sound insulation

- UV Control: from full UV protection to natural UV transmission

- UltraClear: lowest Yellowness Index in industryù

- Decorative & Design: black & white & colored interlayers

600450

600450

Add new comment