Date: 5 July 2023

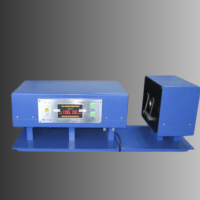

The One-By-One mode in laminated glass production is characterised by:

- Automatic length measurement of the foil

- Pre-cutting of the foil with an automatic foil knife

- Storage on the foil shuttle

- Pairwise glass transport to the assembly table

- Manual assembly of the glass by the staff

Watch the video:

600450

600450

Add new comment