Date: 6 March 2018

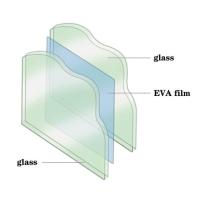

The Lower Austrian world market leader for systems and software for the processing of flat glass delivers the first laminated glass line, developed and built in-house. Since September 2017, the LiSEC group's competence centre for laminating has been located as a business unit in Austria.

An internal acceptance procedure was carried out prior to shipping. This comprised multiple steps and covered all basic functions of each individual machine in the line function.

Marco Bügler, Head of the Business Unit Laminated Glass, at LiSEC: "This glass laminating line, which was completely constructed in Austria, provides the starting signal for the next chapter in the business segment laminating. I am delighted and proud that the team here on the site have integrated this complex technology into the overall range in such a short time."

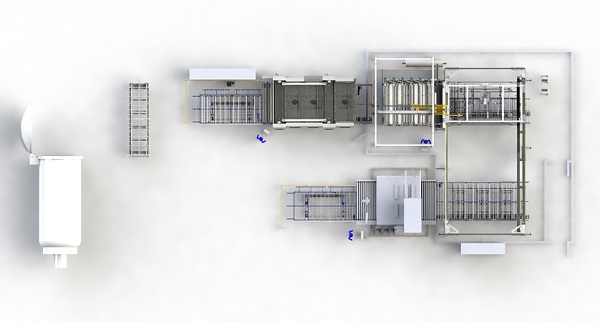

This laminated glass line, sold to the customer Al Hadi in Kuwait, is a U-shape solution for a maximum glass size of 2600 x 5000 millimetres incl. pre-lamination and full convection.

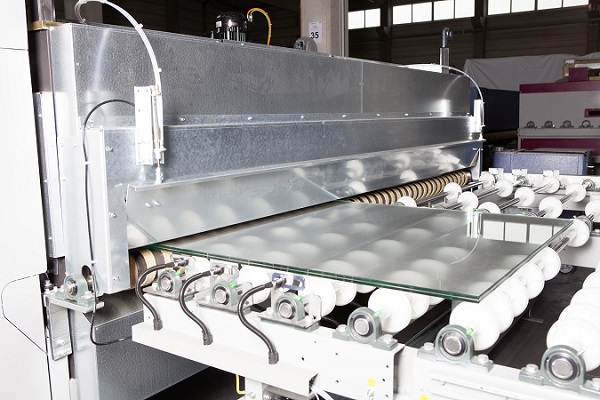

The customer chose LiSEC due to the new technology which is tailored to their needs, and particularly due to the pre-lamination system with high-precision pressing force and full convection system.

In addition, the order books also include plants for customers in Australia, Mexico, Vietnam, etc. Marco Bügler: “For a few months now we have seen a growing interest, we have carried out very promising negotiations and in the meantime, we have shown the "Made in Austria" laminating technology to several customers here in our facility in Lower Austria."

At the moment, LiSEC offers the laminated glass plants with the following maximum glass sizes:

- 2600 x 4500 mm in straight and U-shapes

- 2600 x 5000 mm in straight and U-shapes

- 2800 x 5000 mm in straight and U-shapes

- 2800 x 6000 mm in straight and U-shapes

- 3300 x 6000 mm in straight form

The technological development stages can be adapted to the customers’ requirements and their quality and automation standards.

600450

600450

Add new comment