Date: 22 May 2025

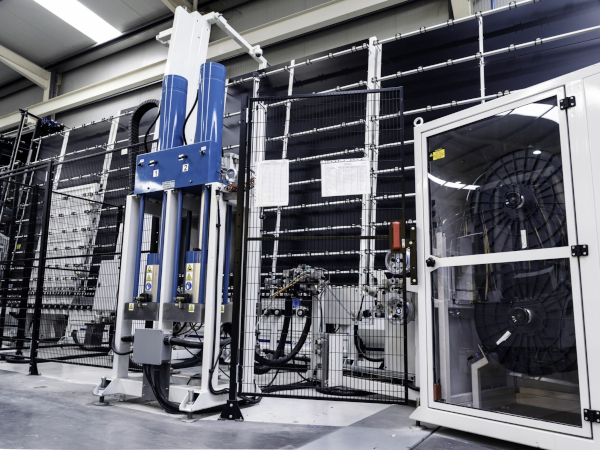

When you buy a LiSEC machine, you are choosing a robust and powerful system that will work efficiently for many years to come. Nevertheless, electrical components generally have a shorter service life than mechanical components. With specific modifications and improvements, the service life of many systems can be extended considerably. This is precisely where the LiSEC LONGLiFE service department comes in: It specialises in meeting these challenges and offers customised upgrades to significantly increase the service life of LiSEC machines.

The benefits of LiSEC LONGLiFE – More than just an upgrade

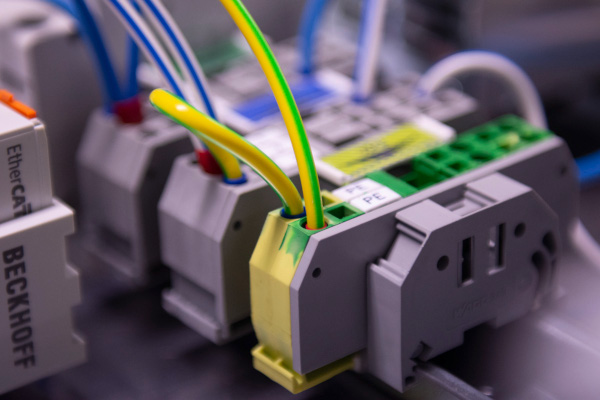

The concept behind LiSEC LONGLiFE is simple but effective: Existing systems are brought up to date by replacing obsolete components and integrating modern technologies. The result is a cost-efficient modernisation that retains the tried-and-tested basic structures of the machine – without the need to invest in a new machine. The popularity of the programme is demonstrated by the fact that the 1000th PC upgrade was recently sold.

As each LiSEC machine is individually tailored to customer requirements, the LONGLiFE programme is correspondingly adaptable. The ongoing refinement of mechanical and electrical components from the latest series is incorporated directly into the upgrades on offer – and is specifically adapted to existing systems.

Another plus point: LONGLiFE solutions make a valuable contribution to saving energy. For example, a new vacuum system for removing dust reduces the energy consumption required for this by up to 85%. At the same time, the carefully thought-out upgrade preparation process ensures seamless installation – with minimal downtime for the customer.

The support offered with LONGLiFE products is swift and simple, as familiar programs and parameter adjustments are used. The upgrades are prepared in such a way that they are configured to the greatest extent possible prior to delivery in order to minimise downtimes on site.

Another benefit of LONGLiFE is its flexibility when it comes to retrofitting. It is not necessary to replace all the electric drives on a production line at once. Instead, the machines can be upgraded one after the other and the old parts can be used as spare parts for the customer’s remaining machines. This enables step-by-step modernisation and reduces ongoing maintenance costs. LONGLiFE solutions also improve the measuring accuracy of older systems, such as edge seaming systems. This leads to more consistent results. What’s more, the functionality of the machine is checked in full during the upgrade process, further increasing reliability.

For customers, this results in improved machine availability, reduced downtimes, and safer and more efficient maintenance processes overall. LONGLiFE is characterised by ease of modification, full functional testing during upgrades and tangible benefits during operation – from energy savings to a reduction in breakages when processing laminated glass.

An excerpt from the LiSEC LONGLiFE product portfolio

- PC upgrades: PC upgrades are crucial, as outdated operating systems can no longer be used effectively. LONGLiFE enables porting to the latest LiSEC hardware, which extends the service life of the machines, guarantees the supply of spare parts and enables rapid support in the event of security concerns, as it enables the latest anti-virus protection programs and cloud-based backup solutions to be used again.

- LENZE drive controllers that have been discontinued or are no longer in production: Declining availability of spare parts and rising prices mean that change is inevitable. Upgrading to the LENZE successor generation ensures long-term planning reliability and technical sustainability.

- Replacements for control terminals that are no longer available: We are now offering a comprehensive retrofit solution with modern machine control panels for older LiSEC systems, such as the VHW washing machine built up to and including 2015. The modification includes all necessary adaptations, including the PLC program update and an amended operating manual.

- Retrofit of an ESL-RS vacuum cleaner: This retrofit enables energy savings of up to 85% during flat glass stripping processes. This corresponds to a reduction of around 4,500 kWh per shift, per year. In addition, the consumption of compressed air and therefore electricity is significantly reduced.

- Retrofit of a KSR edge seaming system for length measurement This retrofit improves the results of edge processing thanks to more precise measurements. The new sensor requires considerably less maintenance than the previous mechanical solution, as the new sensor is programmable and does not require ongoing adjustment by service personnel. The modification also increases the reaction speed of the sensors and thus the accuracy.

- Retrofit of the VB laminated glass cutting machine: When cutting laminated glass, local tension points in the glass are not uncommon and often cause incorrect breakage. By modifying the suction cup mechanism (precise height compensation), which holds the sheet in place during the breaking and separating process, there is no further increase in tension in the glass. This reduces the tension in the glass and therefore minimises downtime and increases process reliability.

Longevity through targeted modernisation

With the LONGLiFE programme, LiSEC is offering a smart solution to the challenges of modern machine maintenance. Instead of incurring high costs for new purchases, customers can rely on proven technology that has been systematically modernised, optimised for energy efficiency and can be flexibly expanded. By combining technical innovation, sustainable use of resources and a customised service, LONGLiFE is the future-proof solution that will extend the service life of your machines.

No matter if it’s individual retrofits or comprehensive upgrades: LONGLiFE ensures that LiSEC systems have a particularly long service life – with maximum availability, minimum downtimes and a clear efficiency advantage. LiSEC also offers the option of replacing entire machines and machine parts to make existing production lines more efficient. Replacing the pre-lamination furnace (PNM) in laminated glass production is one example of this.

Further information on LONGLiFE: https://www.lisec.com/de/kompetenz/after-sale-service/longlife

600450

600450

Add new comment