Date: 5 October 2020

“Although our goal is to be one of the leading smart and safety glass manufacturers in Finland, we didn’t have the time needed to install a completely new furnace,” says Raiko Mäkeläinen, Technical Manager at Lasiliiri. “Instead, we went with a significant Glaston’s FC-zone upgrade, which enabled us to leapfrog to the very latest heating technology in a quick, cost-effective and sustainable manner.”

Lasiliiri is a third-generation, family-owned glass processing business in Riihimäki, just an hour north of Helsinki. Over the years, the company has continued to invest in new technology to grow the business and provide an ever-expanding range of high-quality windows, facades and interior glass.

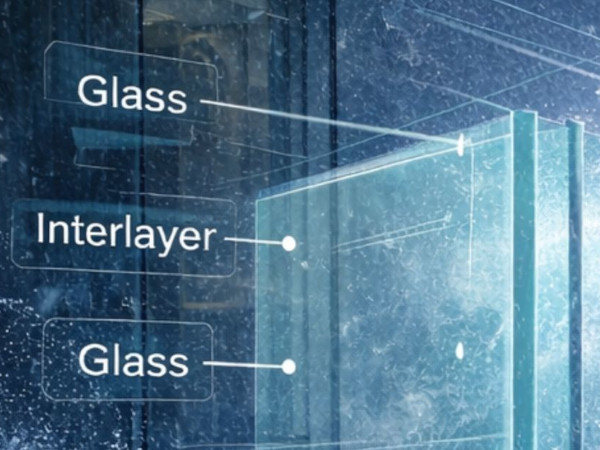

“After investing in 2016 in laminating machinery, the company has been able to explore exciting new types of smart glass, such as PLCDs, LED glass and design products and other types of smart glass to supply a thirsty domestic market.

Lasiliiri’s existing Tamglass tempering machine purchased second-hand and thoroughly refurbished with the latest technology in 2008. “After 10 years, the technology was still solid, but the market had moved towards high-performance coatings and larger glass sizes. Customers wanted multiple coatings and super-coatings to provide sun protection and selectivity. The existing furnace was just not able to do that,” Raiko says.

“We first requested technical information from several suppliers to map out what all the new machinery could do for us. The problem was primarily the heating section,” he explains. Another huge concern was the time that would be lost if Lasiliiri installed a completely new furnace from scratch. That’s when Glaston’s FC-zone with some minor chiller modifications came into consideration.

By just upgrading the heating section of the tempering line and advancing to the latest machine control system Glaston iControL, Lasiliiri could take advantage of a smaller investment cost, less downtime and a shorter delivery time to reach the same capabilities as if they had purchased a new furnace. The entire upgrade took only 25 days. The completed furnace was shorter in length, reducing the line’s footprint. Plus, the machine consumed much less energy, an added benefit.

Read more about the project

Watch the video on FC-zone installation at Lasiliiri

600450

600450

Add new comment