Date: 20 September 2019

A glass bottom and equally transparent glass walls make a swimming pool with unusual views a special eye-catcher. At the same time it functions as a roof light for the display area of an Austrian pool specialist. The two sedak glass elements transform the swimming pool into a so-called “infinity pool”.

They give the swimmer the feeling of a limitless swimming experience at a height of five meters. At the same time they demonstrate the performance capabilities of the material: the pool is around 1.2 meters deep, exerting a load of around 38 tons of water on the 13 x 2.5 meter insulation glass that forms the bottom of the pool. Constant pressure on the glass walls of the pool also challenges the material there.

Photo: Polytherm GmbH

The impression that the boundaries of the pool blend into the surrounding environment is largely a result of the glass edges, which end exactly at water level and also form the outer limits of the roof. The horizon and the water surface thus melt together in a harmonious transition – even underwater the surroundings are easily discernible.

Looking down, the glass bottom of the pool provides the swimmer with a view into the showrooms below and is also a source of light for the interior in the style of an atrium. When the sunlight is refracted by the water surface, interesting light effects are created, providing a unique atmosphere in the room.

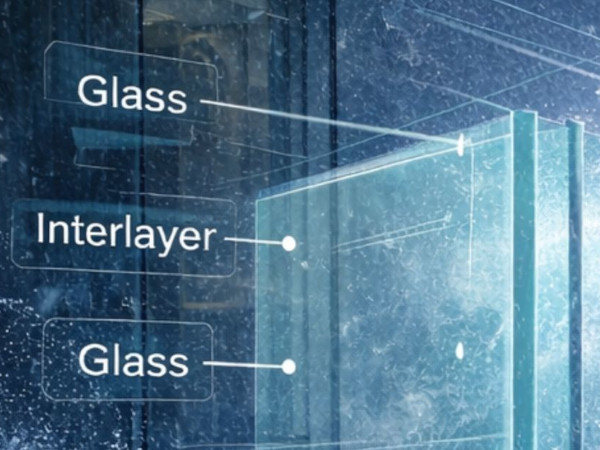

The pool base is a 4.4 ton sedak isotherm insulation glass pane made from a four-layer and a two-layer thermally toughened laminate, each with an SG interlayer. The glass was produced fully automatically as stepped insulation glass on the sedak insulation glass line.

The 80 mm step facilitated the installation of the pool base. The sides of the pool consist of shear-resistant five-layer GlasCobond laminates, also with thermally toughened glass layers (12 millimeters) and SG interlayers (1.52 millimeters), which enable the transfer of high loads.

Photo: sedak GmbH & Co. KG

This example demonstrates how broad the range of possible uses for glass has become. In addition to luxurious private houses, applications for this special pool include, in particular, hotels.

The manufacturer sedak thereby supports planners completely, right up to the logistics: the heavyweight pool base was transported to Weibern in Austria using a specially designed semitrailer from sedak. A film was made of the project, which can be viewed on the sedak YouTube channel.

600450

600450

Add new comment