Date: 3 October 2023

Established in 1976, FG Glass has evolved beyond its initial role of glass processing and procurement. The company plays a pivotal role in shaping architectural landmarks across the globe.

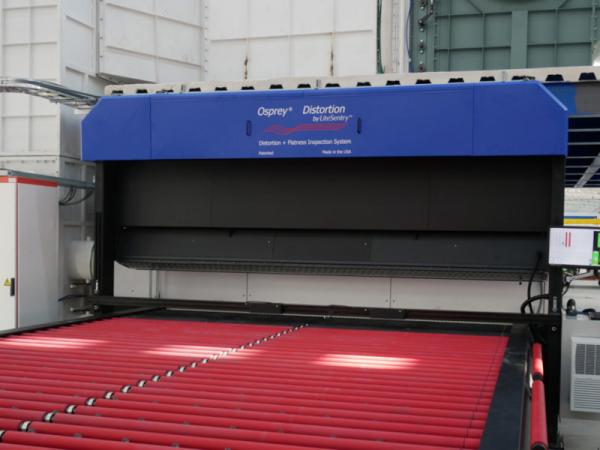

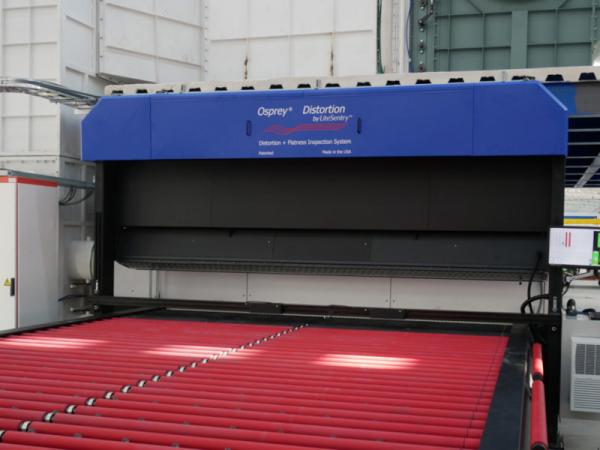

Softsolution takes great pleasure in announcing the successful completion of the installation at FG Glass in India. The Osprey Distortion System, a cutting-edge technology designed for analyzing and monitoring localized distortions during the glass production tempering process, has been seamlessly integrated. This groundbreaking solution empowers clients to enhance the quality of their products and streamline production procedures.

The installation process at FG Glass in India proceeded flawlessly, devoid of any incidents. Softsolution’s expert team collaborated closely with FG Glass to ensure the seamless integration and configuration of the system. In addition, extensive training of the operating staff was carried out to ensure optimal use of the Osprey Distortion System on site.

The positive feedback from the customer confirms that this technology not only meets their expectations, but also meets their requirements.

This achievement marks yet another successful chapter in our partnership with FG Glass. They have already effectively implemented the Osprey Distortion System in a tempering furnace located in the United Arab Emirates (UAE).

The successful implementation of the Osprey Distortion System at FG Glass in India consolidates our position as the preferred partner for innovative solutions in the field of glass processing technology.

Jonas Pfannenstill, Sales Manager at Softsolution, expresses his gratitude, stating, ” We would like to thank FG Glass for the ongoing collaboration and look forward to further opportunities to create value together.”

600450

600450

Add new comment