Others also read

| This text looks at the two systems of vertical and horizontal hot boxes, as well as the laminating cycles for PVB and EVA. It also compares the process to an autoclave PVB laminating process.

| A Review of Essential Requirements towards Standardization

| The new World Trade Center site was rebuilt after 9/11 comprising seven mayor skyscrapers around the memorial site and the 9/11 museum.

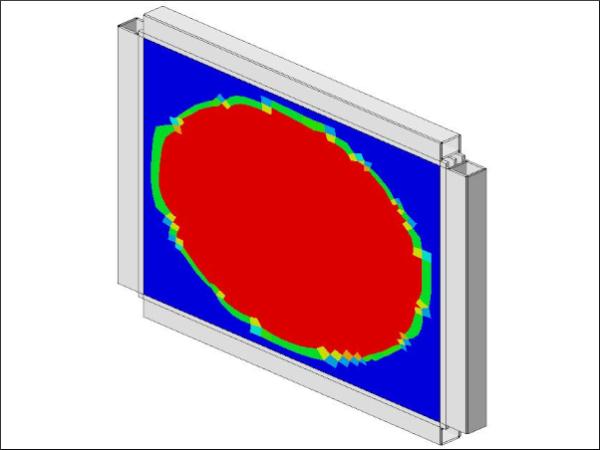

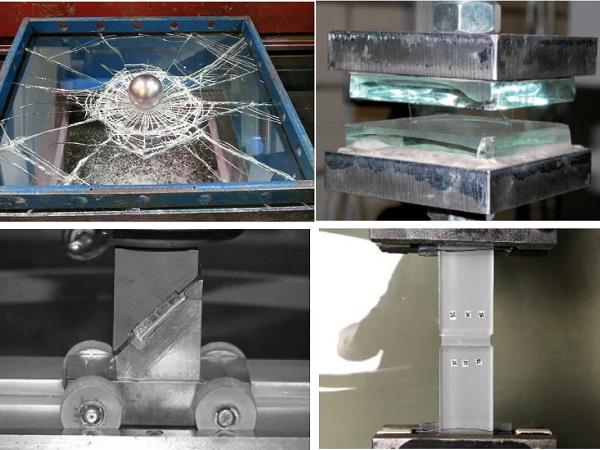

| This paper presents some of major outcomes of Finite Element (FE) numerical methods and simulations that have been explored in the framework of the GLASS-SHARD research project for glass windows and facades under explosion or soft-body impact.

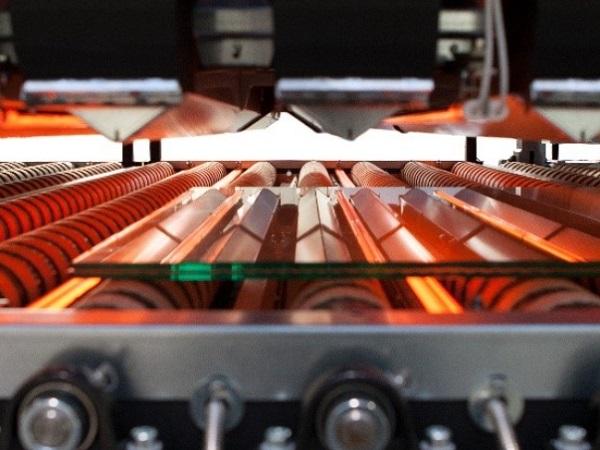

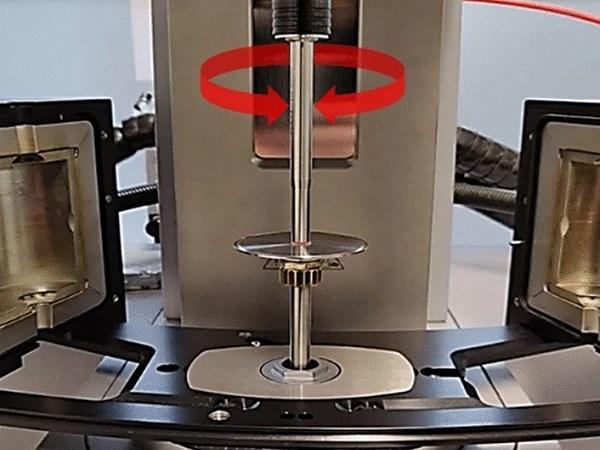

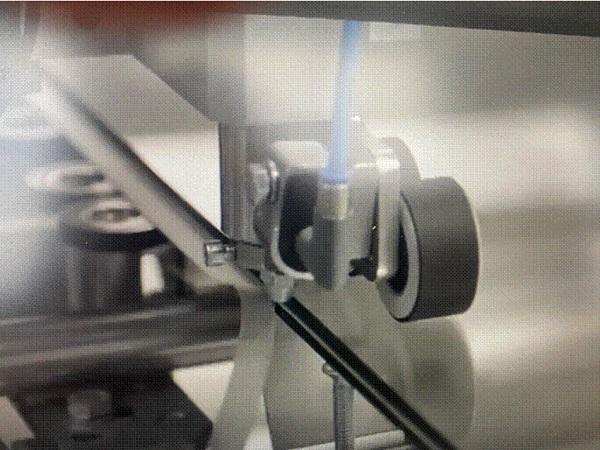

| This text takes a look at the roller process of lamination. It explores different heating concepts such as convection, long wave and short wave IR radiation, and micro-waves, as well as the importance of the correct IR radiation.

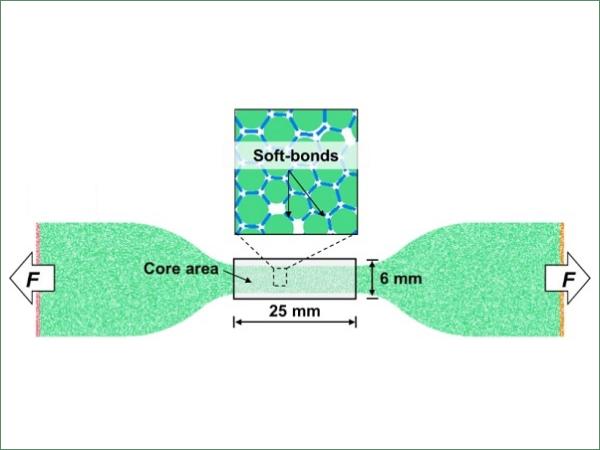

| The bridging behavior between fragments is one vital factor in the post-fracture stage of glass laminates.

| Laminating glass is a process that requires precision and safety. In order to ensure that the glass is laminated safely and to a high standard, special cleanroom requirements must be met. This includes air pressure, clothing, static charges, and cleaning protocols.

| This article explores the various aspects of PVB Preparation, handling, and assembly. It explains how to store, transport, and handle PVB in order to ensure optimal performance and adhesion.

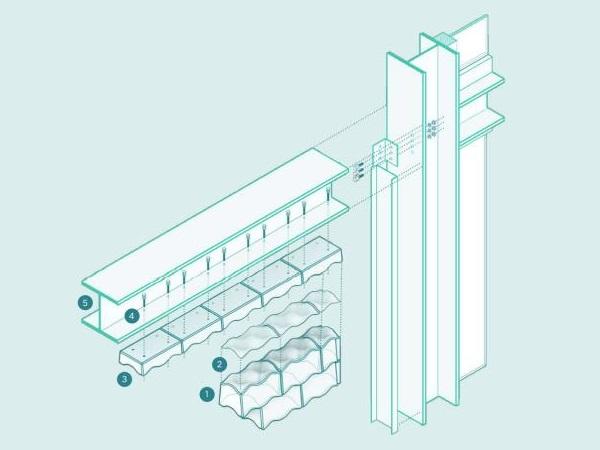

| An Interlayer Material Study Towards Circular, Dry-Assembly, Interlocking Cast Glass Block Structures

| Determination of the linear viscoelastic material behaviour of interlayers with semi-crystalline structures shown by the example of a semi-crystalline ionomer

| When we look at glass lamination, there are 3 basic systems: Nip roller system, Vacuum bag system and Autoclave free system.

| In the next session(s), Luc would like to take you through the 3 glass lamination processes in detail, going from glass and PVB requirements to design concepts.

| The main challenge in the design of the duplex façade was the high aesthetical performance that the façade had to meet.

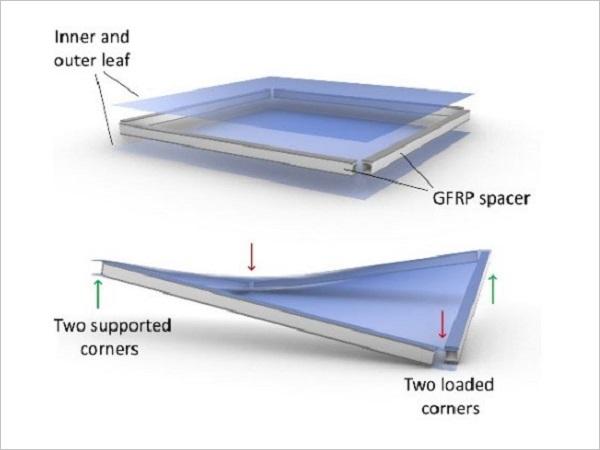

Investigations on the Cold Bending Behaviour of a Double Glazing Unit with a Rigid Edge-Spacer Frame

| In this study, the bending process of specially-fabricated double glazing units (‘panels’) is investigated with a focus on a local instability phenomenon.

| In this paper, we present the development of an intrinsic parameter σQM characterizing the sensitivity of a coating (or configuration) to the quench marks.

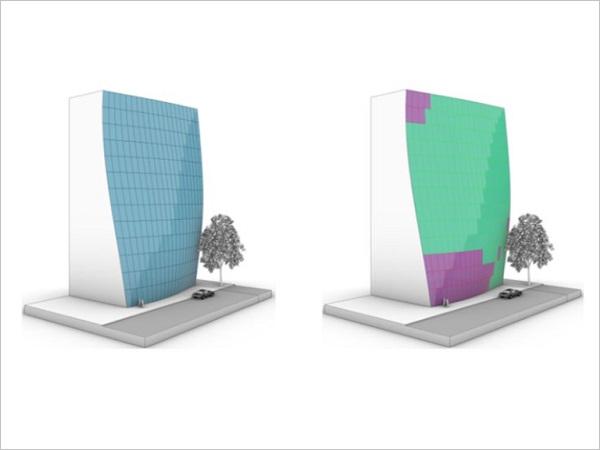

| This paper presents work undergone for a set of four high-rise towers, featuring 11,136 unique cold-bentpanels, hundreds of which are pushed beyond 250mm.

| The paper presents the results of FEM analysis as well as tests performed on double glazed units including Sikasil® IG-25 secondary sealing joints and SikaGlaze® IG-5 PIB as primary seal.

| The paper undertakes a review of basic interlayer stack data with regards to viscoelastic properties and adhesion, and the engineering hypotheses using recent preliminary fitting test results for various loading schemes.

| This paper shows different Pummel classifications that can currently be found on the market. Subsequently, approaches to the automatization and standardization of the execution and especially the evaluation of the Pummel test are shown.

| This paper sheds some light on the challenges to build with high performing glazing façade systems (originally called curtain wall systems) while efficiently utilising resources and reducing its manufacturing embodied carbon.

| This research revolves around the design, fabrication and testing of tubular glass columns, with particular focus on their redundancy and fire-safety mechanisms.

| This study provides a closer look at fire performance of glass beams and proposes further examinations to increase the load-bearing capacity in case of fire.

| “Going ahead of the Curve” is what the advertisement states outside of newly remodeled, Class A office building in Ottawa, Canada.

| Eurocode-compliant, mesh-independent approach using the FEM

| Overview, Case Studies and Future Potentials