This paper was first presented at GPD 2025.

Link to the full GPD 2025 conference book: GPD_2025_ConferenceProceedingsBook.pdf

Author: Vaughn Schauss

Kuraray, United States of America

Abstract

In recent years, an interesting and unique application for laminated glass has emerged. Relying on the strength of laminated glass, designers have begun incorporating structural glass as sides and even bottoms in swimming pools. In response to this trend, members of ASTM's glass strength committee published a new standard: ASTM E3401 Standard Practice for Design and Performance of Laminated Glass Subject to Hydrostatic Loads. This standard provides guidance for calculating the glass strength and for physical testing under hydrostatic loads. Though primarily for swimming pools and aquariums, this standard may provide some benefit for the design of glass flood barriers as well. This paper will review the new ASTM E3401 standard, including examples of calculations, and explore the unique applications of laminated glass under hydrostatic loads.

Article Information

- Published by Glass Performance Days, on behalf of the author(s)

- Published as part of the Glass Performance Days Conference Proceedings, June 2025

- Editors: Jan Belis, Christian Louter & Marko Mökkönen

- This work is licensed under a Creative Commons Attribution 4.0 International (CC BY 4.0) license.

- Copyright © 2025 with the author(s)

1.Introduction

An interesting trend in swimming pool design has emerged over the last several years. Customers and designers want the visual effect of water with no boundaries. Embracing nature’s canvas, the water edge vanishes into the natural landscape. Whether looking at an ocean or mountain view, the pool is transformed into an extension of the surrounding environment. This view is not just from outside the pool, but also from under the water. Incorporating laminated structural glass in pool walls and even floors provide the ultimate feeling of water with no boundaries. Utilizing glass in swimming pools is not a new application as many competition swimming pools have a viewing window installed for recording and analyzing swimmers’ technique; however, this new trend expands on the use of glass and in some cases creating an all-glass pool. While this is an exciting, novel application of laminated structural glass, the questions were raised of how should the glass be designed and are there any applicable standards? To answer these questions, members of ASTM E06.52 Glass Use in Buildings subcommittee began drafting a standard, and the first edition of ASTM E3401/E3401M Standard Practice for Design and Performance of Laminated Glass Subject to Hydrostatic Loads was published in August 2024. This paper will review the new standard and provide some example calculations as well as explore the unique application of laminated glass subject to hydrostatic loads.

2. Review of ASTM E3401/E3401M – 24

2.1. Load Conditions

Before performing any calculations, the load conditions must be defined. In the case of swimming pools, the primary load is the pressure exerted by the water onto the glass, or Hydrostatic, which is defined as “of or relating to fluids at rest or to the pressures they exert or transmit” (Merriam-Webster, 2025). The hydrostatic load may be determined by multiplying the height of the water by its density and gravity as shown in equation 1 below where p is pressure (Pa), h is height (m), ρ is density of the fluid (kg/m³), and g is the gravitational constant (9.81 m/s²).

![]()

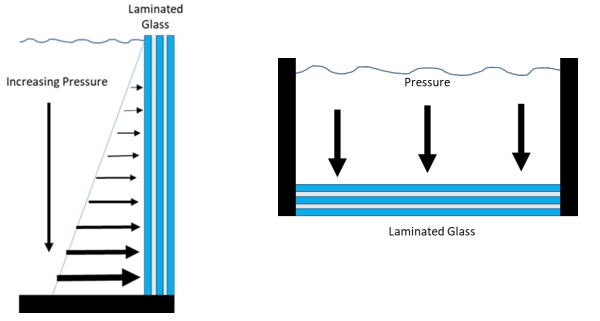

Based on this equation, the pressure exerted on an object is directly proportional to the depth at which that object is submerged under the water. Following this rule, laminated glass installed vertically as a pool wall will experience greater force at the bottom than at the top. This gradual increasing of pressure is depicted in figure 1. In contrast, laminated glass installed horizontally as a pool floor will experience uniform loading in addtion to weight of the glass.

In addition to hydrostatic loads, applications designed for human or animal occupation may experience live loads. For instance, a laminated glass pool wall may be subjected to additional stress from a person leaning on or over the edge of the glass. Similar to a glass balustrade application, when the pool is intended for human or animal occupancy, vertical glass shall also have an additional concentrated live load of 0.89 kN applied horizontally to the glass surface spread over an area of 152mm by 152mm. Likewise, horizontally installed laminated glass in swimming pools intended for human or animal occupancy may experience live loads similar to glass floors or walkways. In this situation, if the water depth is less than 0.49m, a minimum hydrostatic load of 4.79 kPa shall be used in addition to a concentrated live load of 1.33 kN, or more depending on occupant load, over an area of 152mm by 152mm. In both applications, the live load is applied in conjunction with the hydrostatic load and placed in the location that will maximize the stress and deflection.

2.2. Two Paths

Although glass can be designed to withstand high loads, it is brittle and may break. Therefore, in an application like a swimming pool or aquarium, the post-breakage performance of the laminated glass is crucial and must be considered. After establishing the loads, ASTM E3401 allows the design professional two paths to determine the appropriate glass makeup, either a calculation procedure or physical testing. Both methods require verification should one lite of glass break.

Calculation Procedure

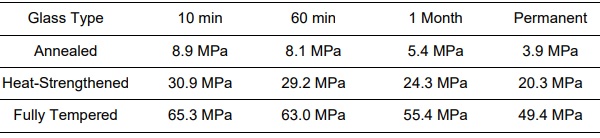

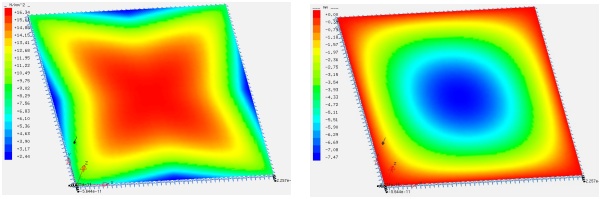

The first path is the calculation procedure which is only permissible for laminates with three or more glass plies. Due to their visco-elastic nature, interlayer properties differ based on temperature and load duration. Therefore, to determine the interlayer’s correct shear relaxation modulus value, knowing the intended temperature and load duration is critical. Considered a permanent load, the hydrostatic pressure has a duration of 15 years, while live loads have a duration of at least 10 minutes. For simultaneous analysis of the hydrostatic and live loads, use the shorter live load duration. When the intended temperature of the water is unknown, 40°C shall be used. Now that the correct modulus values are known, calculate the glass stress and deflection using established engineering methods like finite element analysis and compare the results to the allowable glass stress values given in Table 1. In most cases, the controlling parameter will be the glass deflection, with a limit of L/240 or 13mm whichever is less where L is the longest unsupported span for three-side or fewer supported systems or longest supported length for four-side supported systems. After verifying the laminate meets the stress and deflection criteria in the unbroken state, the calculation is repeated with any one glass ply broken. In the broken state, the calculated stress is limited to the allowable stress at one month.

Table 1: Allowable Glass Stress.

Physical Testing

The other path is physical testing of the glazing system. After determining the load conditions, including the addition of a 2.5 proof load factor, the laminated glass is installed in a watertight tank. Filling the tank to the specified water height, the glass is held under pressure for 22 hours while inspecting for leaks and breakage. If none are observed, the live load is then applied. After passing the live load, one lite of glass is broken and the 22-hour clock restarts. If no leakage or additional breakage occurs, the system passes.

3. Examples

3.1. Vertical Wall

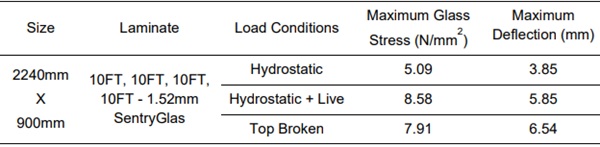

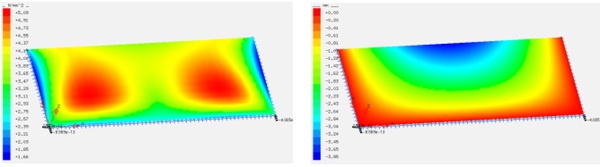

A designer wants to build a swimming pool with a vertical glass wall that is only supported on three sides, at the bottom and two verticals. The glass wall is 2.24 m long and 0.9m tall, and the water depth is 0.9m. Since this project is intended for human occupancy, a concentrated live load of 0.89 KN must be considered. Using equation 1, with a water density of 1000 kg/m³, the hydrostatic pressure is calculated to be 8.83 KPa at the bottom and gradually decreases to 0 KPa at the top. The proposed glass make up is four layers of 10mm fully tempered glass laminated together with 1.52mm SentryGlas. At 40°C and 15 years, SentryGlas has a Young’s relaxation modulus of 8.84 Mpa. Modeling the proposed laminate in Mepla, a commercially available finite element analysis software designed for the glass industry, the glass stress and delfection values are calculated for the hydrostatic load, hydrostatic combined with the live load, and the hydrostic load with one lite broken. In all three scenarios, the calculated values are below the maximum allowed.

Table 2: Results from Example 1 – Vertical.

3.2. Horizontal

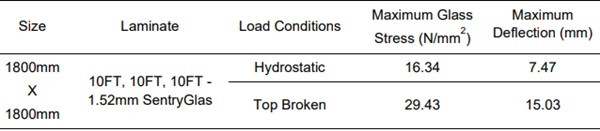

The same designer has another project where the customer wants the pool bottom to be made of glass. The size is 1.8m by 1.8m and is supported on all four sides. The water depth is 1.0m, so no live load is required. Using equation 1, the hydrostatic pressure is calculated to be 9.81 KPa. Using three lites of 10mm fully tempered glass laminated together with 1.52mm SentryGlas, the glass stress and deflection was calculated to be less than the allowed limits.

Table 3: Results from Example 2 – Horizontal.

4. Considerations

Designing laminated glass for hydrostatic loads is not limited to defining the load conditions, one must also consider optics, compatibility, durability, cleaning, inspections, post-breakage performance, and ease of removal or replacement. Laminates composed of multiple layers of thick glass bonded together with interlayers are typically needed to satisfy the design conditions. The resulting laminate may amplify the green color of standard float glass, which in some instance is not desirable. Switchings low iron glass and also specifying a low yellowness interlayer will improve the optical qualities of the glazing. Apart from color, the glass type or heat-treatment is another area for evaluation. Fully tempered glass, although stronger than heat-strengthened or annealed, may exhibit increased distortions due to roller waves or anisoptropy. In addition, the smaller break pattern of fully tempered glass provides lower post-breakage strength. Next item from consideration is once installed, constant exposure to water and sunlight can produce undesired effects on the various materials and components of the glazing system. For example, submerging the edge of the laminate in water could result in delamination. Therefore, the interlayer should be protected from constant exposure to water. To help mitigate potential issues, routine inspection and cleaning of the glass and sealing system should be considered. Lastly, in the event of breakage, having a plan of action to remove and replace the broken glass is critical to minimize the inconvenience and cost. To this end, the ease of replacement should be a factor designing of the system.

5. Flood Resistant Glazing

In the United States, natural disasters like hurricanes, tornadoes, and earthquakes tend to get the limelight of news media; however, flooding causes more damage yearly. Costing close to $5 billion USD a year, flooding can occur in all 50 states and U.S. territories (NOAA). This phenomenon is not isolated to the United States, in fact, flooding can occur on every continent and in every nation. While flood prevention is no easy task and there are multiple avenues to address, designing glass windows, doors and even railing systems as passive flood barriers is a viable option. Leading the way for testing, FM Global, a loss prevention focused insurance company, developed the ANSI/FM 2510 American National Standard for Flood Mitigation Equipment. For this test method, the sample, installed in a waterproof chamber, is subjected to water filled to a specified height for 22 hours. After inspecting for leaks, the sample is exposed to wave-induced hydrodynamic load conditions. Next, the specimen is impacted twice by simulated floating logs that are 30cm and 43cm in diameter and weigh 277 kg and 358 kg respectively. Each log impacts the specimen traveling at 2.1 m/s followed by a post impact hydrostatic load. The system is then inspected for leaks to determing pass or failure. Since this is a time consuming test, it is not easy to quickly retest should the glass fail. Using the calculation procedure of ASTM E3401 may aid in designing the glass for testing these passive flood barriers. Thus potentially saving time and money.

6. Conclusions

Designing swimming pools and passive flood barriers made with laminated glass is now possible with ASTM E3401. This new standard provides a path to calculate or physically test glass subjected to hydrostatic loads. Whether its protecting communities from flood waters, or offering a unique swimming experience, laminated glass offers exceptional clarity without blocking the natural landscape.

References

- Hydrostatic. Merriam-Webster.com Dictionary (2025, 27 March), Merriam-Webster, retrieved from https://www.merriam-webster.com/dictionary/hydrostatic.

- Standard Practice for Design and Performance of Laminated Glass Subject to Hydrostatic Loads, ASTM E3401/E3401M-24, ASTM International, 2024

- Severe Weather 101 – Floods (2025, 29 March), retrieved from NOAA National Severe Storms Laboratory, https://www.nssl.noaa.gov/education/svrwx101/floods/faq/

- American National Standard for Flood Mitigation Equipment, ANSI/FM 2510-2020, ANSI, 2020

Comments

Laminated glass provides significant benefits, such as protecting communities from flood waters and creating a distinct swimming experience. This type of glass ensures exceptional clarity, allowing for an unobstructed view of the natural landscape while maintaining safety and durability.