Date: 2 June 2020

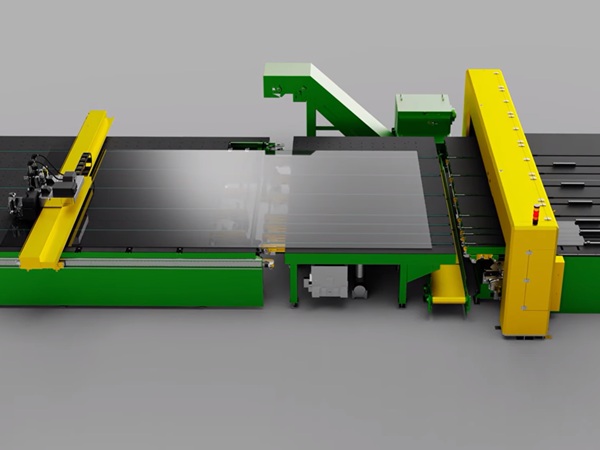

Available in widths up to 2.7 meters, the roll format gives processors and laminators far greater flexibility. Rolls are not only easier and more efficient to store, but they also promise less wastage compared to the sheet-supplied variant.

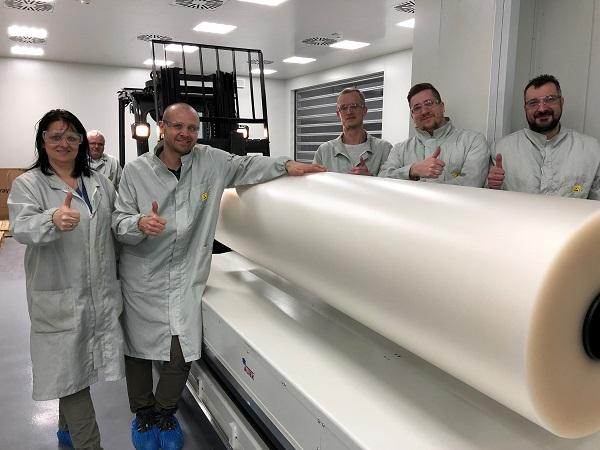

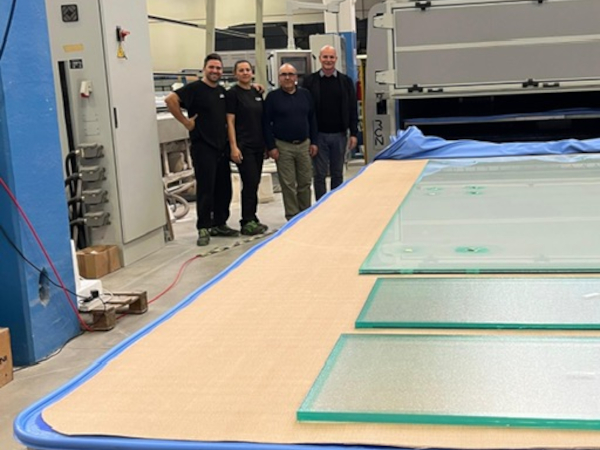

The Holesov plant, which started production of SentryGlas® earlier last year, can produce rolls with calipers of 0.76 and 0.89 mm. What is more, the exceptional roll flatness on offer from the new plant results in improved lamination efficiency and throughput.

Photo: Trosifol/Kuraray

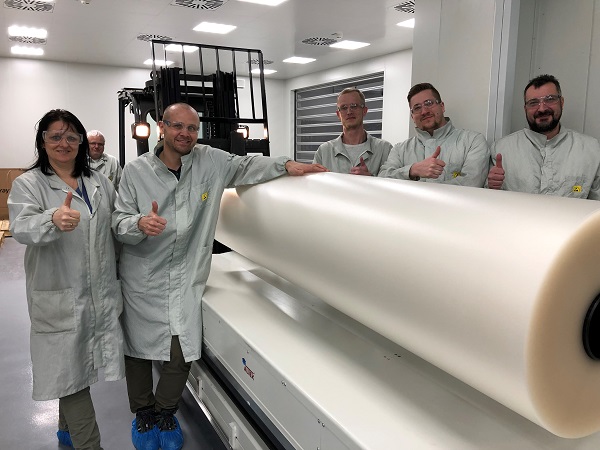

Photo: Trosifol/Kuraray

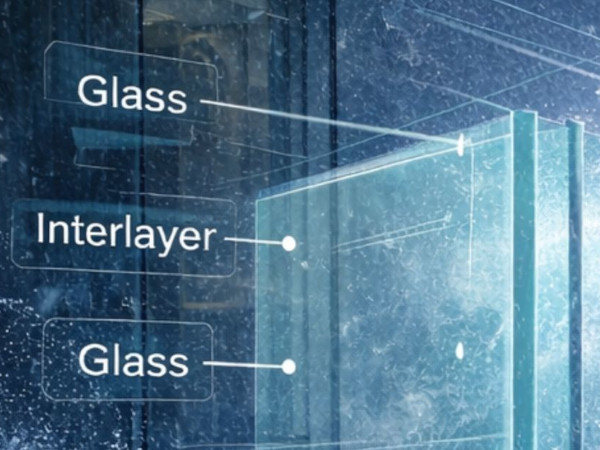

SGX™ – in both roll and sheet form – improves lamination processing efficiency and streamlines processing, while still delivering the highquality laminate construction and outstanding operational performance synonymous with the SentryGlas® brand.

Of particular interest to laminators is the reduced risk of haze formation caused by an inadequate cooling rate. Adhesion to the airside of glass is significantly improved too, with adhesion primers no longer being required.

These features, combined with the roll format, will make multiple-ply laminated glass assemblies easier to process while delivering the potential to increase the number of laminates in autoclaves, increasing throughput efficiency.

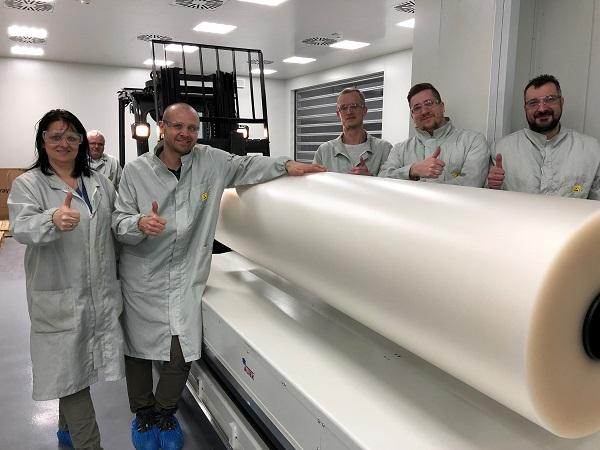

Photo: Trosifol/Kuraray

Photo: Trosifol/Kuraray

Trosifol is the leading global producer of PVB and ionoplast interlayers for laminated safety glass applications in the architectural segment. With the biggest product portfolio worldwide, Trosifol offers outstanding solutions:

- Structural: Trosifol® Extra Stiff (ES) PVB and SentryGlas® ionoplast films

- Acoustic: Trosifol® SC Monolayer and Multilayer PVB films for sound insulation

- Trosifol® PVB film for UV control: From complete UV protection to natural UV transmittance

- Trosifol® UltraClear PVB film for the lowest yellowing value in the industry

- Decorative & design: Black-and-white, color and printable interlayers

600450

600450

Add new comment