Date: 15 February 2019

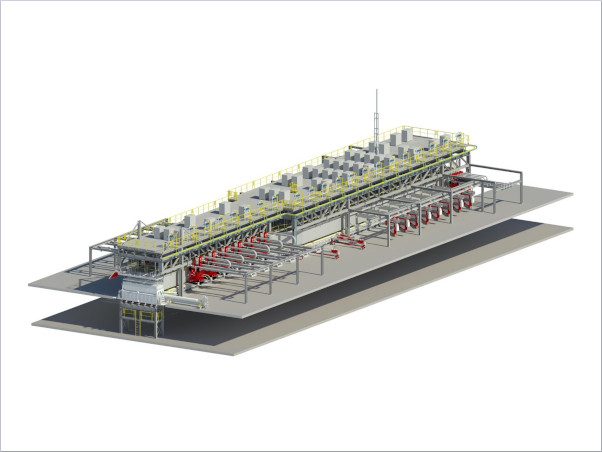

Forvet S.p.A. is a specialist builder of glass industry plants. The company’s developmental focus is the integration of multiple flat glass production processes into one machine. The most recent result of this work is the modular Combiflex line which combines eleven processing steps into a footprint of just 33 square meters.

The end-to-end, state-of-the-art automation concept is based on Siemens control and drive technology. The Combiflex is the only machine in the world which can accommodate completely different products and market segments and reliably achieve high production volumes, thus increasing overall production efficiency.

Grinding, polishing, drilling, notching, countersinking, water jet cutting, corner rounding, engraving, mitering, washing and drying – the Combiflex achieves a great deal and is loaded and unloaded upstream and downstream by robot loaders and stackers.

No operator interventions are required in the fully automated process from flat glass to finished product. The Combiflex facilitates the production of, for example, shower doors, furniture glass, mirrors and architectural glass. The work cycle of the three axis CNC machining center is controlled by a Siemens Simotion motion control system.

Comprehensive motion control

The motion control system recognizes the shape and thickness of the incoming glass and adjusts the equipment to the appropriate settings for what is to be made.

It controls the tools and the removal of the glass as well as the machining feed operations, and compensates the tool wear. Up to five workpieces can be machined at the same time so that, for example, all the machining work for a 10-millimeter shower door can be completed in less than 200 seconds.

Everything in place for future projects

A Simotion system also controls the interaction between the modular Sinamics S120 converters and the Simotics S servomotors. Other components from the Siemens portfolio include Sinamics V70 servo drives for standard positioning tasks. A robust Simatic industrial PC handles order management and process visualization.

“Siemens is one of the few suppliers that can cope with the complexity of the hardware and software in our Combiflex line,” summarizes Sebastiano Bisotto, Project and Automation Manager at Forvet. A further benefit of the Siemens solution is the scalability and the end-to-end Profinet communication which allows functionality to be extended in the future without any problems.

600450

600450

Add new comment