Date: 25 September 2019

QUALITY BECOMES VISIBLE

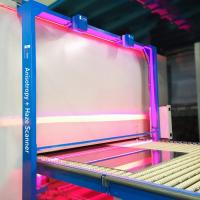

The SOFTSOLUTION LineScanner already convinces more than 500 customers worldwide with reliable glass quality control.

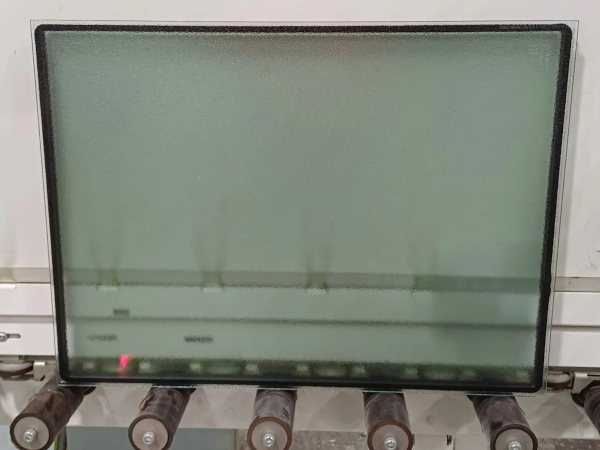

Transparent flat glass products such as single glass, insulating glass, automotive glass, polycarbonate and films are checked with the utmost precision.

The LineScanner is assembled directly at our headquarter in Waidhofen / Ybbs - Austria, where the individual components are supplied by regional suppliers and put together with the utmost care.

Afterwards, the LineScanner will be set up at the customer's site by our experienced technicians and the staff will be trained on the device.

600450

600450

Add new comment