Others also read

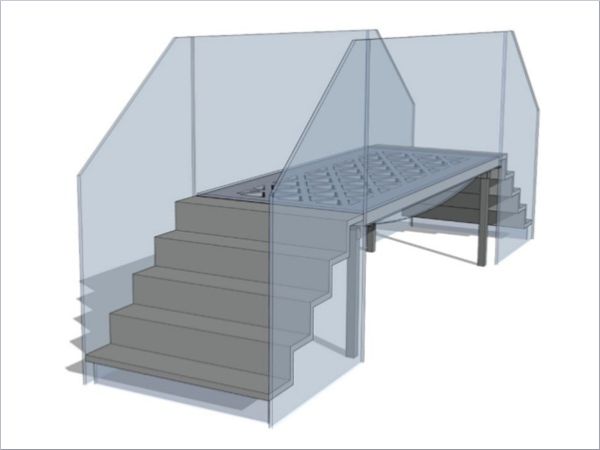

| This article presents how the pioneering G2C (Glass-to-Concrete) project is redefining construction by successfully integrating bonded glass and concrete into a full-scale pedestrian bridge demonstrator.

| This study demonstrates how fibre-reinforced and ultra-high-performance concretes enable structurally bonded glass-to-concrete systems, opening new possibilities for efficient, sustainable, and visually striking hybrid structures.

| A new study explores how smarter structural design and adhesive optimization in glass-metal façades can significantly cut embodied carbon while maintaining performance and integrity.

| Understanding how glazing systems behave under blast conditions is essential for designing safer, more resilient façades.

| Laser technology is rapidly reshaping the future of glass processing, offering a level of precision and innovation that traditional methods can’t match.

| As the façade industry advances in sustainable glass coatings, it’s time to look beyond energy performance and focus on human-centered design—exploring how light, spectrum, and transmittance impact our wellbeing.

| Smart glass, simplified. Meet OSSE, Organic Semiconductor Materials for Sustainable Electronics, from the University of Turku.

| A new paper explores the complete process and equipment innovations enabling the handling, cutting, and manufacturing of ultra-thin boro-aluminosilicate glass for architectural applications.

| Advances in architectural design and energy-efficient construction are reshaping expectations for modern glazing solutions.

| At Step Change 2025, ReViSalt demonstrated how its innovations are reshaping the future of glass strengthening.

| Fresh from Step Change 2025, Lithium Designers GmbH, the Frankfurt-based innovators transforming façade planning through parametric design and 3D-printed nodes, shared their insights on how technology is reshaping the future of architectural design.

| The path to low-carbon, high-performance facades depends on mastering the long-term thermal behavior and lifecycle performance of Insulating Glass Units (IGUs).

| At Step Change 2025, in connection with Glass Performance Days 2025, eLstar Dynamics wowed us with their smart glass tech that dynamically shifts from ultra-dark (0.1% transparency!) to crystal clear (up to 70%).

| Viprotron has developed a new technology for the exit of the furnace, that allows the measurement of the distortion of tempered glass with high precision and unparalleled repeatability.

| ASTM has introduced a new standard, ASTM E3401, to guide the safe use of laminated glass in swimming pools, aquariums, and other applications subject to hydrostatic loads.

| Thermal stress relief treatment offers a promising solution for enabling the reuse and remanufacturing of end-of-life tempered glass, paving the way for more circular economy practices in the flat glass industry.

| New international standards are reshaping the way modern façade glass is designed, balancing security performance with comfort, safety, and multifunctionality.

| Discover how TPS® boosts IGU longevity and energy performance in this Glastory blog and download the presentation.

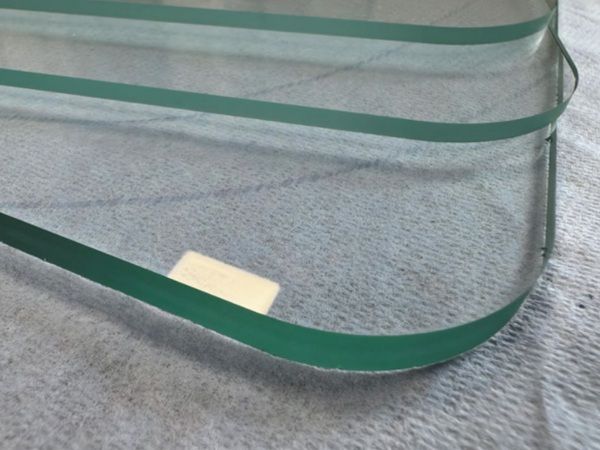

| The growing use of glass in modern architecture has increased the importance of laminated safety glass (LSG), prompting new research into how production processes impact its long-term durability and safety.

| Dive into the blog to learn how cutting-edge solutions are making ultra-thin glass production possible—and scalable.

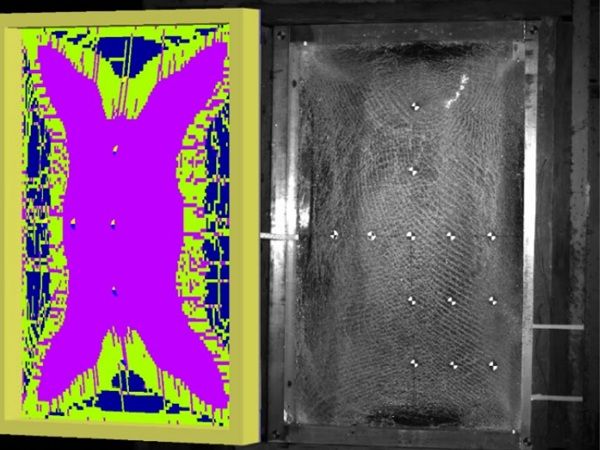

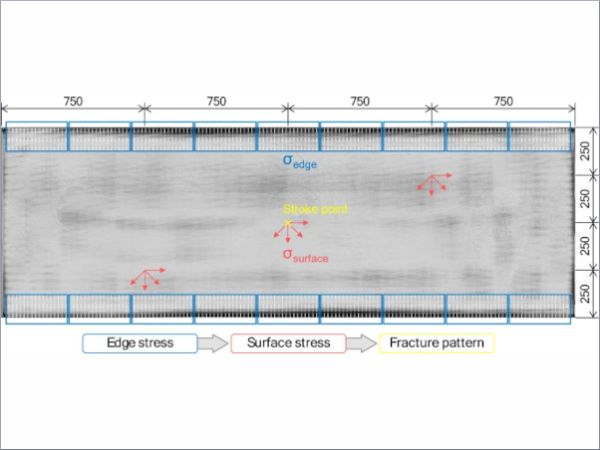

| New research explores how non-destructive photoelastic methods could improve quality control for large-format thermally toughened glass, reducing reliance on costly and time-consuming destructive testing.

| Understanding how glass behaves under high temperatures is essential for improving the safety and performance of glass structures exposed to heat and fire.

| This paper presents an experimental campaign employing an electric radiant panel as the heat source to investigate the heat transfer phenomena in glass.

| This paper encompasses design, manufacturing, and experimental testing to assess the feasibility of using glass AM to produce interlocking masonry units for the construction industry.

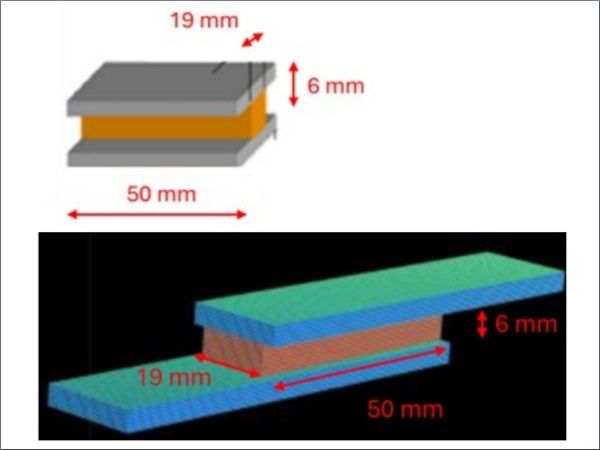

| This paper presents investigations on a novel approach for post-tensioning laminated glass beams with adhesively bonded iron-based shape memory alloy tendons along both longitudinal glass beam edges.