To mark the 25th anniversary of the global No. 1 trade fair glasstec, held in Düsseldorf from 23 to 26 October 2018, the proven special show glass technology live will provide new impulses: a cluster comprising four universities and renowned exhibitors will present innovative and visionary solutions covering four selected focal themes at the special show in Hall 11; complementing these the glasstec conference will combine scientific theory with hands-on practice.

Photo: Daria Scagliola & Stijn Brakkee

Transparent Visions

The special show glass technology live forms an integral part of glasstec. This year the special show will address the four focal themes Interactive Façades/Display Glass, Energy and Performance, Structural Glass (thick glass/thin glass) and New Technologies.

In cooperation with four Technical Universities (Darmstadt, Delft, Dresden and Dortmund) and selected businesses Messe Düsseldorf will be showcasing forward-looking technologies in Hall 11. Furthermore, the glasstec conference will provide information on the latest developments while also picking up on current research projects from the special show.

The essential and typical characteristic of glass is its transparency – a property that laid the foundation for the appeal of this material millennia ago and that has not ceased to fascinate with its versatile applications until this very day. From the early period through antiquity to the Middle Ages glass manufacturing has been constantly refined and specialised.

By the introduction of industrial-scale production glass became an affordable mass-produced product on the one hand, and machine-based glass technology also opened up hitherto unknown possibilities for glass finishing, on the other. Last but not least, digitalisation brought completely new fields of application such as interactive façades and energetic functions.

Photo: Faidra Oikonomopoulou

glass technology live under new guidance and with a new concept

glass technology live at the world’s leading trade fair glasstec in Düsseldorf fuses both the said advances made in glass technology and the undreamt-of possibilities of this tradition-rich material. The special show has been part and parcel of the trade fair for 20 years now and has long since been considered a key impulse generator for the international glass industry.

Originally initiated by Professor Stefan Behling, Senior Executive Partner at Foster + Partners, and the Institute of Building Construction at the Stuttgart University and designed, organised and characterised by him and his team for over two decades, glass technology live now celebrates its 25th anniversary completely re-vamped: a cluster of four universities instead of one has worked out the conception for the special show.

Each one of the four universities addresses its own focal theme and presents ground-breaking exhibits from the area of technology, manufacturing and glass applications. The cross-industry spectrum of themes covers ranges from automotive through consumer products to construction and interior design.

While TU Darmstadt outlines visions in structural glass engineering and uses new technologies to make their realisation graspable, TU Delft introduces the matching new glass types and glass construction typologies. In contrast to this, Dortmund University covers interactive façades and the energetic functions of glass.

Illustration: TU Delft, Frank Auperlé

Dresden University, finally, worked out the potential that gluing holds as a joining technique for glass construction. Almost three quarters of the exhibits on display at the special show are first “releases”, university research projects, experimental concepts or award-winning works from student competitions.

Themed “Meet the Expert” sessions and the newly conceived glasstec conference give glass technology live visitors an additional opportunity to make personal contacts, attend interesting lectures and take part in topical expert discussions.

Innovations from Universities and Pioneering Exhibitors

The area occupied by glass technology live in Hall 11 is divided up into four segments dedicated to the aforementioned focal themes of the four universities. Here, some extraordinary exhibits can be found. The common denominator of all exhibitors is that they showcase completely new ways of using glass as a material.

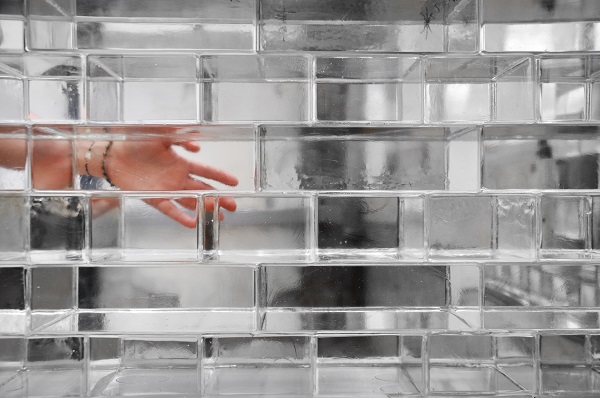

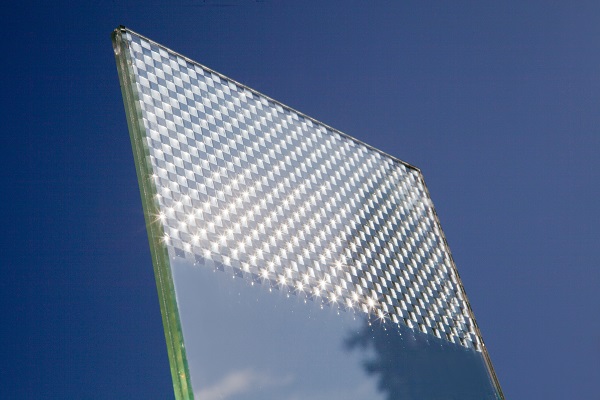

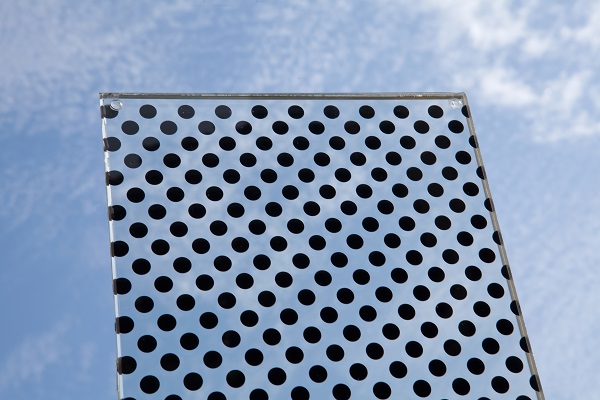

Seen GmbH, for example, deals with reflecting shapes. Micro shapes with a metallic reflection in glass reflect light and colours here in all directions. The individual elements are highly customisable. The choice of surface ranges from highly and semi-reflective metals to multi-coloured iridescent colour coatings.

Photo: Seen

The shapes available are squares, rectangles or circles sized between two and twenty millimetres. Up to five different types can be fixed at any chosen distance on the transparent substrate that is introduced as a two-sided insert into laminated sheet glass or laminated toughened glass.

Uniform lines and grid structures are feasible as well as partial areas, graduated shades and logotypes. Elements coated on one side produce an intriguing effect. The different thermal expansion coefficients of the various surfaces produce a slight curvature in the individual shapes during the lamination process so that a three-dimensional effect is produced.

Photo: Seen

Elbe Philharmonic Hall – Glass Re-Staged

Opened in 2017 the Elbe Philharmonic Hall in Hamburg has set new standards in many ways. Its unique features are the bent, multiple coated and printed multi-purpose insulating glass sheets that produce special light effects on the building skin.

Josef Gartner GmbH, a company of the Permasteelisa-Group, clad the buildings with custom-made glass panes over a total area of 16,000 square metres. Never before had multi-functional insulating glass units been produced with a curvature along just one glass edge. To this end the glass panes were first printed, then coated and finally bent precisely according to specifications at a temperature between 500 and 600° Celsius.

Photo/Copyright: Cordelia Ewerth

About 500 of the approx. 2,200 glass elements inserted are spherically bent. Another 1,700 units were inserted flat but all elements are made of low-iron oxide glass to ensure particularly clear views. Both element sizes were produced with an outside curvature and with an inside curvature offset by 350 millimetres towards the inside.

Oval pivot windows allow the rooms to be naturally ventilated. Each pane of the façade features a chrome dot screen print and a second coloured dot screen print. The small reflecting chrome dots vary, thereby making each window element a one-off. In the area of the two concert rooms six inside terraces were built.

Photo/Copyright: Cordelia Ewerth

5 m high and 6.45 m wide so-called tuning forks made of glass fibre reinforced plastic accept three spherically bent panes each and open the façade to the loggia located behind it like an inside balcony.

In the flat wing of the building these tuning fork elements are 5 m wide and 3.33 m high and accept two spherically bent laminated security glass panes printed with dot screens. The latter will be on show as sample elements from the Elbe Philarmonic Hall alongside other Gartner exhibits at glass technology live.

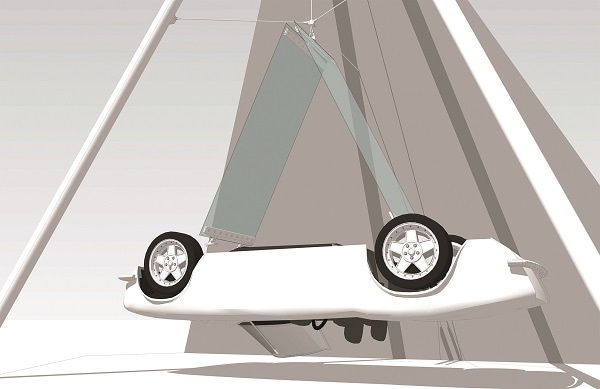

The exhibit provided by Define Engineers, Carpenter/Lowings and seele is about gravitation in the broadest sense of the word. It demonstrates technological progress in glass processing, adhesive development, high-precision technology and manufacturing.

Photo: Define Engineers

A car turned upside down is suspended from just two thin glass panes between a steel tripod. The laminated panes measure 1 x 2.20 m and consist of two 2mm, partially pre-stressed glass sheets provided by Glaston that were laminated with SentryGlas by sedak. The primary connection with the glass is realised with Dow’s transparent TSSA silicone structural adhesive.

Another superlative is the world’s biggest bent glass sheet with a curve length of 8,000 mm and a height of 3,200 mm in thermally pre-stressed glass presented by Northglass. A specially developed furnace technology allows heating and cooling the glass on transport rollers all the way. With this process the best optical quality of the bent glass can be ensured.

Photo: Tianjin NorthGlass

Niemeyer Sphere

In the listed brick buildings of the Kirow-Werke in Leipzig one of the last designs by architect Oscar Niemeyer (1907-2012) is currently taking shape. The project is based on a spherical design that embraces the existing building while also forming a contrast with it.

The sphere consisting of white exposed concrete with two large, curved window “cut-outs” hosts two storeys. The window cut-outs are geodesic domes with a triangular division. The matching partner for realising this project was found in Merck and their Liquid Crystal Window-Technology” (LCW) for self-shading double-glazed units.

One prerequisite for the project was the development of a neutral grey shade that attains a very high degree of transparency in its initial state. This can be switched gradually either automatically or at the touch of a button to a very dark grey so that the energy transmittance can be reduced substantially if need be.

At the special show glass technology live in Hall 11 Merck presents a true-to-scale model of part of the building. This demonstrator is made up of 50 different triangular sheets measuring approx. 1.4 x 1.4 m and supported by a steel structure.

All the other manufacturers mentioned here by way of example will also be showcasing their special solutions in Düsseldorf. Whoever wants to know what the industry is speculating about today, what they will be discussing tomorrow and indeed producing the day after is urgently advised to visit the special show at glasstec 2018.

Interactive façades, display and thin glass, forward-looking glass technologies for generating energy as well as developments and possibilities in structural glass engineering: all of this can be marvelled at, touched and critically questioned.

Whichever message visitors take home from this special show: they will feel they know where the glass industry stands today in terms of technology, which challenges it has already met and which visions might soon become reality.

The Authors

Dipl.-Ing. (FH) Claudia Siegele, freelance architect and specialised journalist, Matthias Fischer, specialised journalist and textbook author.