The individual colour nuances of the glass are based not only on technical parameters but also on specific environmental influences and personal perception.

A correct interpretation of the complex interaction between these different influencing factors is a prerequisite to ensure that the eventual overall impression of the building will conform to the client's objectives.

Different glass types such as thermal, solar or combination glasses differ not only in their physical function, but also in their optical appearance. 'Because individual glass products produce different effects in their outward appearance and personal perception plays a decisive role, skilful sampling is becoming more important than ever', says Bruno Gygax, responsible at EUROGLAS for the SILVERSTAR coatings for Glas Trösch.

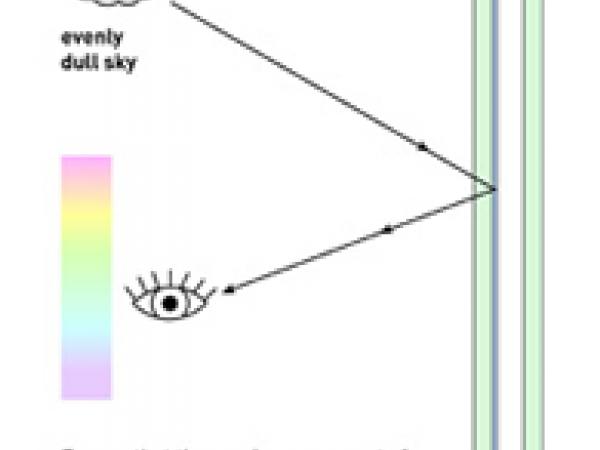

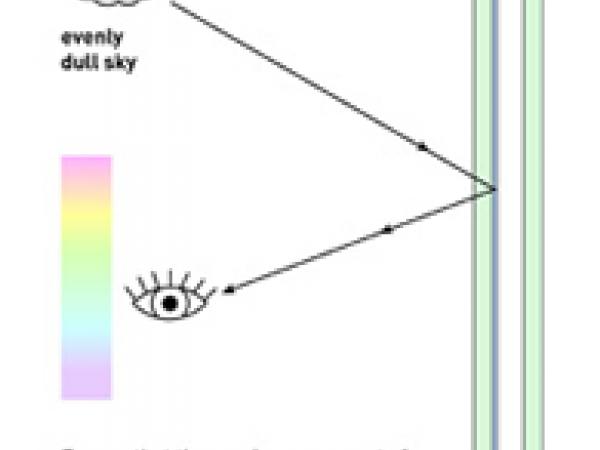

Correct sampling - for perfect results An optimal condition for sampling is a uniformly overcast sky. Ideally, this should largely be reflected in the glass when looking at the facade. Furthermore, the sample facade or the hand sample should be viewed through an angle of 90 degrees if a true colour impression is to be obtained. Under a very sharp viewing angle there may be colour shifts in the external effect as the light is reflected as long wave radiation from this angle.

Reflection and transmission colours can be simulated against various backgrounds: The colour that is reflected outward at the coating of the glass, the so-called street appeal, should be evaluated against a black background. By contrast, for sampling the transmission colour, which influences colour perception inside the room, a white background is preferably used. Usually, DIN A4 hand samples can be obtained from manufacturers.

However, these can only give a first optical impression. Especially for large-area glass facades more extensive sampling is important.

For this purpose, EUROGLAS not only has sample exhibitions at its production plants but also a roadshow: A 15m long truck houses all coated glass products for solar and thermal protection. The most reliable method for the sampling of a glass application is to set up a sample facade at the construction site. Using the original facade and insulating glass set-up has the great advantage that also the interaction with other materials such as steel, aluminium, concrete or wood can be verified.

How is colour created? The properties of the glass such as its inherent colour, glass thickness, coating design, position of the coated glass in the insulating glass and coating materials (metal oxide) determine, in combination with the environment, the actually perceived colour nuances. Thus, the coating of a glass that produces a bluish effect reflects the blue component of the visible solar radiation.

The remaining colours of the spectrum penetrate the glass facade almost unhindered and determine the transmission colour. The exact definition of a colour is usually a purely technical matter for which a L*a*b* colour system is used: via lab measurements the relevant colour nuance is allocated a point in a three-dimensional coordinate system. The three coordinates describe both the red-green and yellow-blue components and the lightness. These technical values can however not replace the on-site evaluation.

A neutral surface, which, for instance, is surrounded by blue hues, is perceived by the eye with a light yellow shimmer according to the principle of complimentary colours. That is why for sampling it is advisable to take into account not only the site but also the time of year and day as well as the position of the sun and the weather conditions.