Date: 18 September 2019

Glass as a load-bearing construction material in the building industry is a challenge. Safety regulations are high, and glass is inherently fragile. At the VDMA in Frankfurt on 28 August, the participants discussed how it is nevertheless possible to design and build sophisticated architecture based on glass.

Glass as a load-bearing construction material in the building industry is a challenge. Safety regulations are high, and glass is inherently fragile. At the VDMA in Frankfurt on 28 August, the participants discussed how it is nevertheless possible to design and build sophisticated architecture based on glass.

The event focused on cutting flat glass, material models as well as laminating glass.

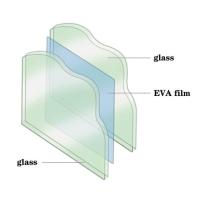

In addition to a low risk of injury in the event of breakage and good sound insulation, the residual carrying capacity is decisive. The quality of the intermediate layer in the laminated safety glass (LSG) is decisive. It can be made of PVB, EVA, thermoplastic polycarbonate or an ionomer material (SentryGlas®). This is associated with very different, complex material models.

Delamination can occur, so it is important to simulate it and take possible risks into account beforehand. This requires a huge amount of data in order to achieve better models for a harmonised assessment basis. One possible way could be monitoring facades using artificial intelligence. Permanent measurements and data generation using sensors could capture and evaluate factors like wind, sun, rain, shade or pressure over a longer period of time.

In future glass construction projects, this data could be incorporated in advance, and actual projects could benefit from an early warning system. This sounds simple but is still in the experimental stage. This is where the universities are in demand, because these analyses are very complicated and time-consuming. In industry, the most common test methods are still pummel test, ball drop impact test or bake test.

Depending on the purpose for which the glass is intended, films with different adhesion properties are used. Factors such as temperature and humidity have a considerable influence on durability and adhesion. In warmer areas, for example, only SentryGlas® may be used to ensure the shear stiffness of the laminate.

The demands on LSG due to external influences are increasing. Forces of nature such as severe storms or the danger of terrorist attacks require even more resistant glass for special applications. While in Asia for a long time it was believed that typhoons could do no harm to the facade glass, in September 2018 typhoon Mangkhut gave the inhabitants of Hong Kong a lesson.

Much more than gluing

Not only the composition, but also the manufacturing process of laminated glass is complex. Glass panes are stacked alternately with other materials and bonded together. Laminating with a flatbed laminator allows flexible processes because the batch is formed on the conveyor to the laminator. Heat transfer by contact brings the heat symmetrically and homogeneously into the products.

The compound to be produced can be optionally heated up separately with adjustable temperature. This process is particularly suitable for the production of composites with different glass pane thicknesses. If several laminating steps are required, this can be done at different temperatures. The process overall is energy-saving due to the constant temperatures, short cycle times and compressed working processes.

It's the edge that counts

Industrial cutting of large flat glass panes is often still carried out mechanically by scratching with a cutting wheel and subsequent breaking. Crack generation, crack system and component strength are closely related. In addition to the depth crack, the cutting wheel also produces lateral cracks and chipping, which runs towards the glass surface. A deep crack as long as possible with high stress at the crack tip is necessary for a properly broken edge.

Like the other crack types, it forms when the load is relieved, after a short load application. Indentation tests clearly show that the resulting secondary radial cracks can have a decisive influence on the component strength due to their direction.

Among other things, the quality of the cutting edge depends on the mechanical construction of the cutting machine, from the guide of the cutting head up to the stiffness of the supporting base on which the glass to be cut is placed. Adjustments and thus interruptions in the operating processes cannot be completely avoided.

Laser cutting is an increasingly common method. This can be done, for example, with an ultra-short pulse laser (UKP laser) with pulse durations in the ps range or fs range. Cutting with this method is a combination of laser filamenting and heating to apply the necessary stress. Lasers can also drill, structure, mark and decoat. Depending on the application and the glass, different types are used. UKP lasers, for example, enable stress-free drilling from bottom to top with wavelengths of 523 nm or 355 nm. Today, laser processes can ablate aircraft paint about 500 times faster than before, for example to create the shark skin surface on aircrafts.

A major advantage of laser applications is the reduction of post-processing steps. Many users in the industry would like to have variable lasers for the various fields of application, but this is still a dream of the future and only possible to a limited extent in individual cases for scientific research.

600450

600450

Add new comment