Date: 10 October 2023

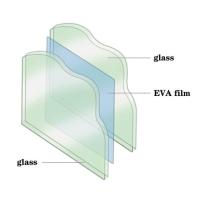

Glass lamination involves several related jobs, among which the cleaning of the edges at the end of the process.

It consists in using blades, thermo-cutter or any sharp toll, to remove the exceeds of the interlayer. And with REVA BF being very strong, it is a difficult job. This is the compromise for using a high adhesion product.

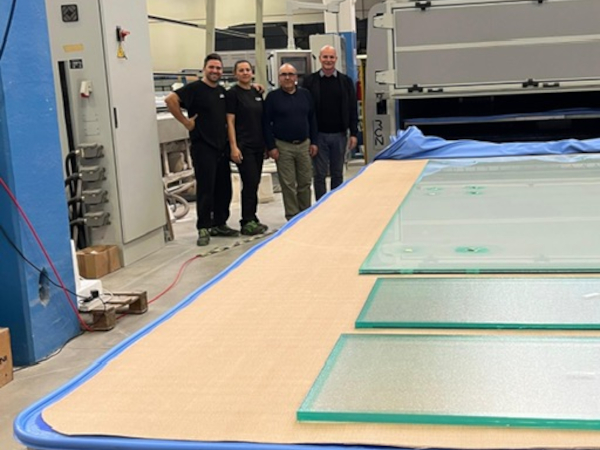

In the last twenty years, RCN SOLUTIONS has assisted customers to find solutions about this problem but a definitive one was still far to arrive. Finally, in 2021, the RCN’s R&D department has focused on cleaning of the edges not after but during the process, preventing EVA to squeeze too much from the laminated glass.

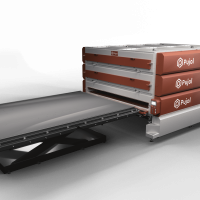

The result has been RD CLEAN CONCEPT, a system based on a last generation bags, having different features from the common ones and able to offer some benefits:

- Clean edges after lamination

- No need for blades, cutters or sharp tools to clean granting safety of the operator.

- Save time and labour costs

- Total flatness of the laminated glass

The last point may seems less evident but RCN has noticed that regular bags tends to press too much on glass edges with the consequence the laminated glass is not as flat as expected, creating visual distorsion. RD CLEAN CONCEPT prevents this problem, leaving the glass surface totally flat because it distributes the pressure on the full glass surface, not just on the edges.

The product is patented since end of 2022 and has another important quality: it has not competition.

And if customers are wondering whether RD CLEAN CONCEPT can be installed in existing kilns or kilns different from RCN’s ones, we are ready to satisfy all demands.

600450

600450

RCN Solutions RD Clean Concept is a game-changer for glass lamination. Not only does it save time and labor costs, but it also ensures clean edges, enhances operator safety, and delivers flawlessly flat laminated glass, all while having no competition in the market. This innovative solution is a must for the modern glass industry. | elevator service San Antonio