Date: 8 September 2014

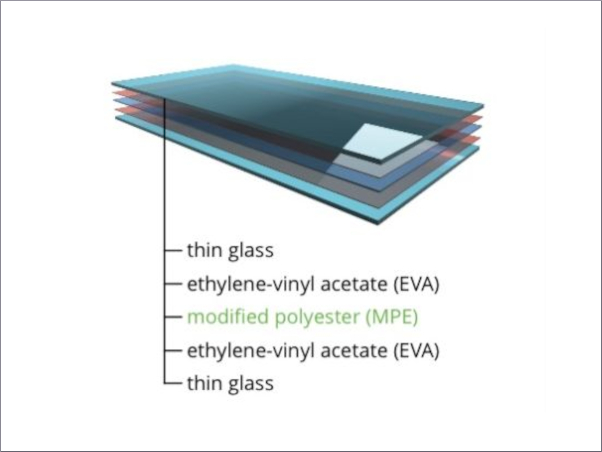

This makes the use of moisture- and heat-resistant films that join glass and adapt to different conditions even more crucial. evguard® EVA film, which Folienwerk Wolfen will be presenting at glasstec from 21 to 24 October in Düsseldorf, is resistant to moisture and UV rays and is particularly useful in the field of design.

Design knows no limits. Design inserts can be embedded between the glass and the lamination film in the processing stage. The low processing temperature of as little as 105 C allows stylistic elements such as blades of grass, coffee beans and even wood to be embedded in glass. Frameless glass applications, like staircase constructions made of glass, can be created without sacrificing quality or safety, because evguard® cannot be stretched and, despite its low weight, does not lose stability under high loads.

evguard® can also be used for glass laminations with coloured or transparent effects in combination with printed insert films or glass. This allows artistically valuable stylistic elements to be realised. The design benefits can be seen in the properties of the EVA film: the material bonds well with nearly all surfaces and displays excellent adhesion to glass and other surfaces. In addition to the elasticity and strength of the film, evguard® has a long lifespan, making it suitable for the one-way vision effect that is becoming increasingly popular in bathroom environments in particular.

“The field of glass design presents challenges for both products and manufacturers. With evguard®, designers have a high-quality film for glass lamination that adjusts to individual surface conditions”, explained Steffen Bornemann, Project Manager in the Research and Development Team at Folienwerks Wolfen. “evguard® makes possible stylistic elements in glass design that forge completely new paths for the industry.”

600450

600450

Add new comment