Date: 28 July 2021

Oh how nice life would be if all glass finishers had just 3-4 main glass types in stock and they were accustomed to yields of above 90%. But that was a long time ago.

Today, an insulated glass manufacturer regularly cuts approximately 80 to 150 types of glass, increasingly coated glass, LAMI, and other expensive lites. From this glass, he produces an ever-higher share of triple function insulated glass in many combinations, with different spacers, gas fillings, and sealing materials. Processors are also confronted with much greater product complexity.

When this development increased, the industry was surprised to see lower yield values, some of which were below 80% - just like before the introduction of intelligent IT-controlled optimizations. And the better the sequences for production and delivery were planned, the worse the waste became.

Intelligent solutions were urgently needed, in insulated glass and in processing. And the more complex the products became, the more difficult it was to bring the best yield into harmony with perfect sequences.

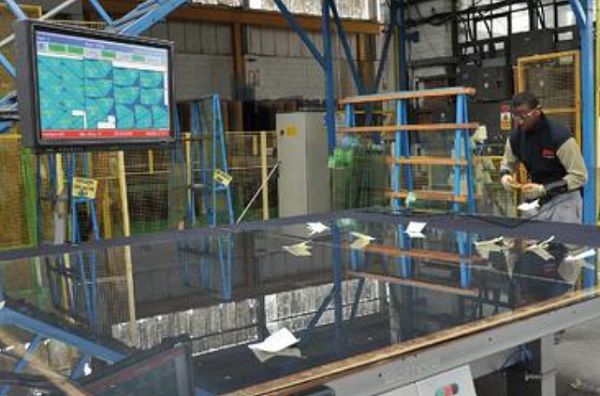

Today, A+W optimizations are no longer isolated solutions in cutting; instead, they work intelligently with one another and with state-of-the-art system technology in complex systems all across production to achieve outstanding results. For the industry still wants to be profitable.

2004 brought an important breakthrough: A+W presented A+W DynOpt. For the first time it was possible to use mechanical sorting systems to establish each desired production sequence automatically - with the highest yield. There are practically no more residual lites. Increasingly, medium-sized companies have also been using A+W DynOpt.

But this intelligent optimization doesn't work by itself: it requires "teammates" in capacity planning, flexible batch formation, in the furnace, in delivery logistics. And not every processor needs A+W DynOpt; there are a lot of other exciting solutions ….

Before we explain the details of the modules in our optimization system, here's something you should know: before batch formation, there should be careful capacity planning with the A+W Capacity Planner! This way, your A+W production and optimization systems "know" early on what capacities are available, which ones are already fully utilized, and which ones, e.g. due to maintenance and breakdowns, should not be planned in. In addition, the system can determine the most cost-effective production path through the multitude of processing machines. This way, you avoid dead-end streets and bottlenecks even before batch formation and you create the greatest value possible.

600450

600450

Add new comment