The tool allows users to upload their own images and designs or start from scratch. CloudWall is one of several tools being developed for ShopFloor, a web-based platform that allows designers to have their creations built on Zahner’s factory floor.

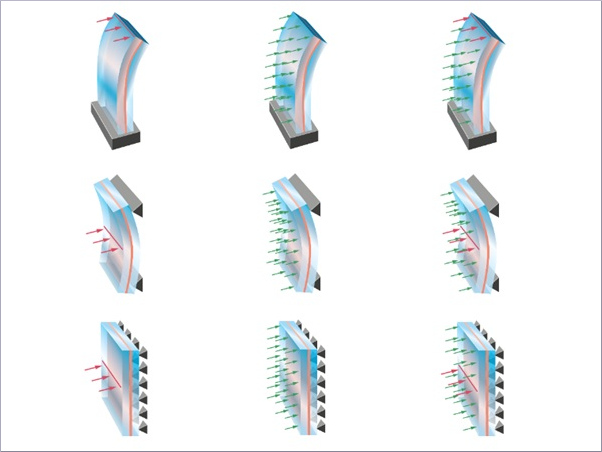

Creating a design with CloudWall is simple. A user can upload an image, and watch the tool generate vertical fins at varying depths resulting a unique design on the surface of a facade.

The tool could give architects a streamlined approach to creating flagship stores. A business could feature an image relating to their line of work, or even their logo, subtly grazing the surface of their building.

.jpg)

.jpg)

Once you play with the tool for a few minutes, you realize how fun and simple it can be to fabricate a world of visually astounding works — all at costs that are comparable to installing something as banal as a custom building awning.

Watch CEO/President Bill Zahner and Project Engineer Craig Long describe how CloudWall works:

CloudWall is based on Zahner’s facade in Kansas City. The north facade of their headquarters features a billowing curtain wall designed by Crawford Architects in collaboration with Zahner engineers.

Zahner’s new CloudWall software provides a less expensive alternative to build custom architecture using metal. The cost of building the Zahner Headquarters in Kansas City was upwards of several hundred thousand dollars. Similar designs created with the CloudWall software can be fabricated and shipped for a fraction of that price.

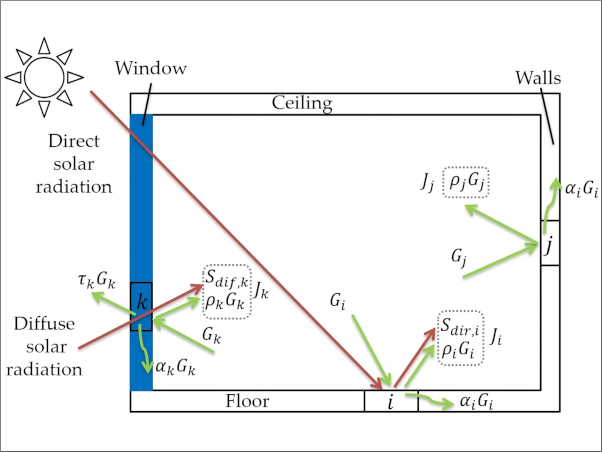

The CloudWall application allows for a variety of color options for the fins, and the back panel can be specified in any material offered by Zahner, including patinas on zinc and copper. As the user makes these changes, they can watch the price update in real time, allowing users to effectively control the price.

“We’ve built a tool that uses our factory floor like a massive rapid prototype machine,” says Mr. Zahner, “You see the price, you manipulate your design, and then we build it. This model has never been applied to architecture.”

.jpg)

Designers can see the price change as they change materials, tweak the design and adjust parameters. After making the purchase, Zahner produces the parts, crates the assemblies, and ships them to the job site.

The tool currently limits designs to 25’ high by just less than 80’ wide on rectangular buildings. If a user wants to customize the design beyond the parameters of the web-interface, they can contact Zahner and work with an engineer.

The CloudWall tool is one of several being released over the next few months under ShopFloor. Purchases made with ShopFloor include the price of engineering, fabricating, and shipping the assemblies, and does not currently include an option for installation of the parts.

You can signup for Zahner’s software platform, and watch the video at azahner.com/shopfloor.

CEO/President Bill Zahner in front of the CloudWall system at Zahner Headquarters in Kansas City.

Image courtesy Travis Wears.

Users can upload their own images to manipulate their designs.

Image © A. Zahner Company

Screenshot of CloudWall™ Application for ShopFloor™

Image © A. Zahner Company

Engineer Craig Long provides a demo of the CloudWall™ on his laptop.

Image courtesy Travis Wears.

User can see instant pricing as they make changes to their designs.

Photo © A. Zahner Company

Image © A. Zahner Company

Designers can export and download a 3D Model of their design.

Image © A. Zahner Company

.jpg)

Photograph of the Zahner Headquarters in North America.

Photo credit Tex Jernigan.

.jpg)

Photograph of original design by Crawford Architects on the Zahner Headquarters in North America.

Photo credit Mike Sinclair.

When the company was founded in 1897 by Andrew Zahner, they primarily produced two kinds of product: decorative cornices, and skylights manufactured with wire glass. It is no small wonder that today, the company is sticking to these roots.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)