This paper was first presented at GPD 2023.

Link to the full GPD 2023 conference book: https://www.gpd.fi/GPD2023_proceedings_book/

Authors:

- Dominik Offereins¹ | Alexander Pauli¹ | Geralt Siebert¹

- ¹ University of the Bundeswehr Munich

Abstract

In the field of bonded joints in structural glass construction, many different polymer materials have been tested in recent years. The bandwidth ranges from foil sheets used as an interlayer for laminated glass (LG) or laminated safety glass (LSG), over structural silicone sealants for linear joints to high-strength adhesives such as acrylates or epoxy resins for point-fixings. However, so far only the silicone and interlayer materials are in widespread use. To gain further insight into the material behavior of high-strength adhesives, two UV-curing acrylate adhesives are investigated in tests on the bulk material by uniaxial tension tests and dynamic mechanical-thermal analysis (DMTA).

UV-curing acrylate adhesives combine the advantages of easy application with a transparent appearance, the latter being to some extent a basic requirement for glass constructions. In addition, a comparatively wide range of material stiffness can be set, which is represented by the selected adhesives: on the one hand, a very stiff adhesive was chosen (in the following referred to as “Acrylate 1”), which is applied in layer thicknesses in micrometer scale and smaller surface areas, and on the other hand, an adhesive that is used as an interlayer of laminated glass (“Acrylate 2”). Thus, the description of 'high-strength adhesives' is put into perspective to a certain extent, and potential fields of application are not limited to point-fixings only.

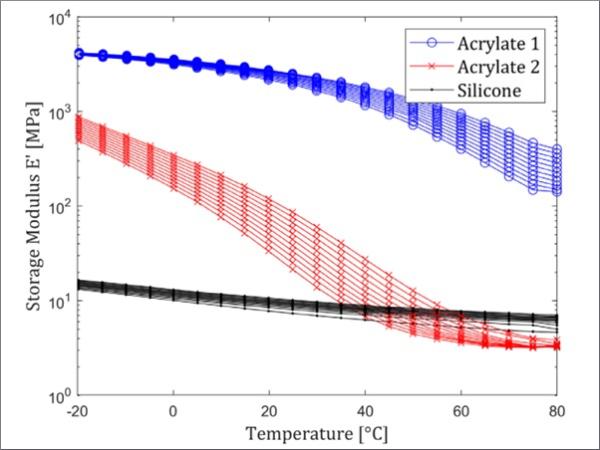

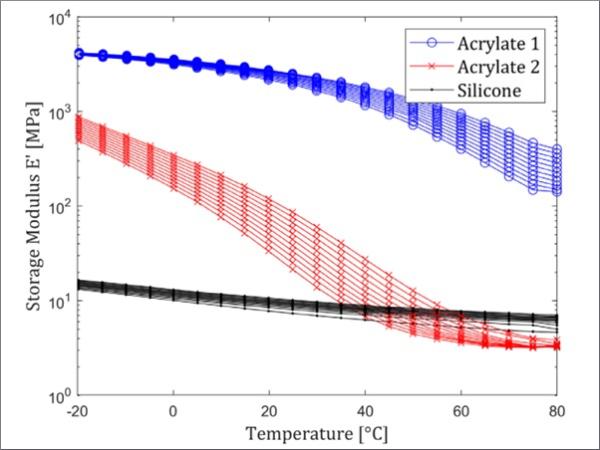

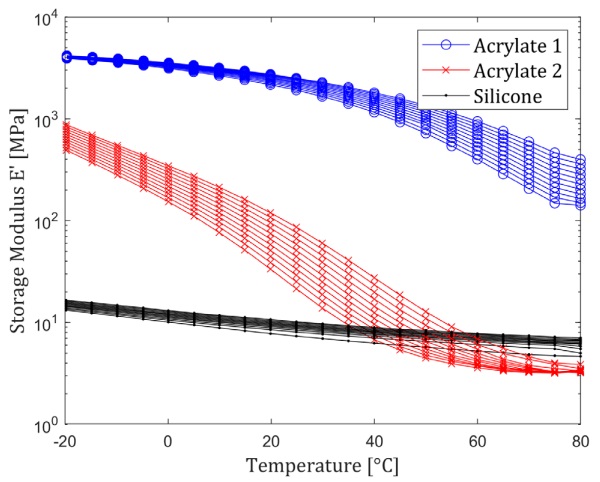

In order to examine the adhesives with regard to linear-shaped bonding, a comparison with the method of structural sealant glazing is essential. In the tensile tests, which were each carried out under two different strain rates, Acrylate 2 and the silicone showed similar behavior. However, in the DMTA tests increasingly large differences occurred as temperature decreased. This can be attributed to the different glass transition temperatures, which in the case of silicone lies in a temperature range considerably below 0 °C and thus ensure constant material behavior in the service temperature range (-20 °C to +80 °C). As a result, the storage modulus of Acrylate 2 is about 50 times higher than it is for the silicone at -20 °C but at temperatures of 65 °C and above, the modulus of the silicone is higher. In comparison, Acrylate 1 still exhibits high stiffness values at 80 °C and shows no decisive rate dependence.

By means of the ‘GUSTL’-Algorithm [1], the data from the DMTA tests are used to construct the so-called Mastercurves for Storage Modulus and Loss Modulus over a wide frequency or temperature range, respectively. From these Mastercurves, a linear viscoelastic material model in the form of a Prony series is derived and used in [2] for further numerical simulations.

This research paper is funded by dtec.bw – Digitalization and Technology Research Center of the Bundeswehr. dtec.bw is funded by the European Union – NextGenerationEU.

References

[1] Kraus M.; Niederwald, M.: Generalized collocation method Using Stiffness matrices in the context of the Theory of Linear viscoelasticity (GUSTL). In: Technische Mechanik 37 (2017), Nr. 1, S. 82-106

[2] Pauli A., Offereins D., Siebert G.: Numerical Modelling of UV-curing acrylate adhesives. Glass Performance Days (2023)