Date: 25 July 2016

At the AAMA Southeast Region Summer Meeting, Carrie Davis, PE, from Protection Engineering Consultants (PEC) – a San Antonio-based structural and mechanical consulting engineering firm – presented a primer on blast-resistant design , focusing on how blast loads differ from and interact with “traditional” loads, what government or industry criteria are available as design tools, recommended design approaches and advanced analysis tools for complex glazed systems.

Blast Load Basics

Shock waves are NOT like wind loading. The design goal is to dissipate the incident energy through system flexibility and allowable movement.

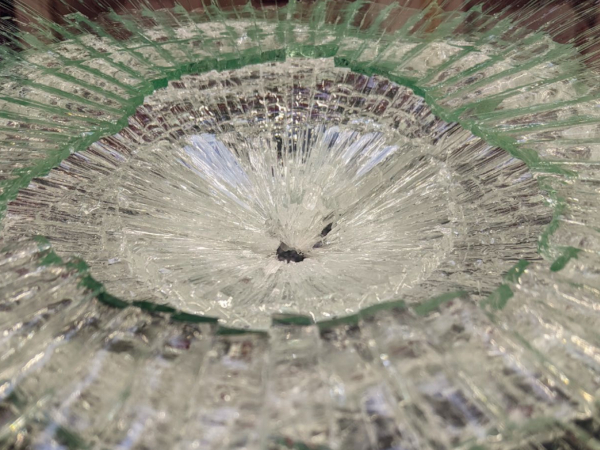

Most injuries that occur during a bombing event are associated with airborne window debris, i.e., glass shards or large pieces of framing or glazing.

Davis compared load characteristics and dynamics of a blast load to traditional load considerations and looked at design approaches to account for them.

Load profiles are different (traditional loads: static pressure; blast loads: dynamic/impulse pressure). Windloads are based on ASCE 7, while blast loads are unique to the explosive weight, stand-off distance, etc.

Design Criteria

There are many government and industry criteria available for the design of building envelope components to withstand blast loads.

Blast-resistant design criteria may follow pathways set forth in AntiTerrorism and Force Protection (ATFP) criteria. ATFP design seeks to prevent loss of life by allowing significant damage to the structure, in which glazing is designed to fracture but not cause hazards.

Criteria include well-developed design loads and response limits as defined for each government agency. Two primary resources are:

- General Services Administration (GSA)-TS01 (latest edition January 2016),Standard Test Method for Glazing and Glazing Systems Subject to Dynamic Overpressure Loadings, which defines five performance conditions to indicate whether and how far glass shards penetrate into a room when the window and wall segment are subjected to a blast of specified peak pressure and impulse. The Interagency Security Committee (ISC), composed of 26 member agencies, was later created to adapt GSA’s Security Criteria for all federal buildings except those under Department of Defense (DOD) jurisdiction, which had their own requirements.

- DoD (United Facilities Criteria [UFC] 4-010-01 [updated October 2013]), emphasizes occupancy level and site plan (standoff distances). It uses dynamic analysis to meet the applicable Level of Protection (LOP) and prescribes testing per ASTM F1642; laminated glazing may be designed per ASTM F2248 static design approach.

“Generally, less defined criteria results in more restrictive design requirements,” said Davis.

A Different Design Approach

Davis recommended an improved design approach that groups performance considerations by task rather than by discipline. Instead of looking at all elements of the system separately under the disciplines of blast design, wind and gravity design and seismic design, then reconciling them into a final design, PEC suggests looking at designing members in terms of size and stiffness to meet architectural requirements, wind deflection criteria and seismic requirements, then upsizing as necessary for blast loads.

This is followed by designing of connections in terms of serviceability under thermal, seismic and architectural requirements (wind, dead load, etc.), then sizing the connections to accommodate blast loads. In essence, the idea is to “accommodate serviceability requirements before designing for strength.”

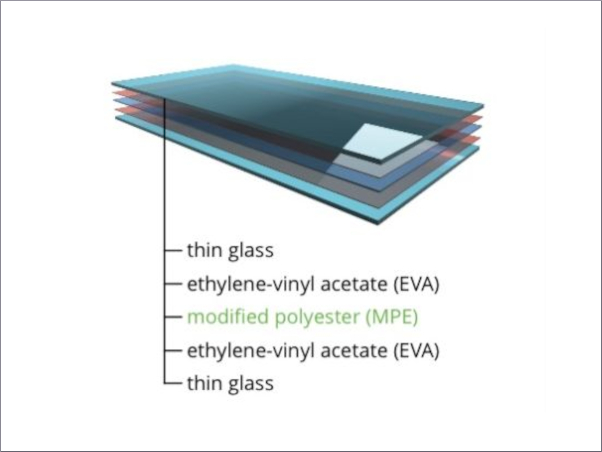

“Coordinate early and understand all the applicable requirements of your project,” Davis said. Common design solutions include using laminated glass attached to aluminum or steel frames using structural silicone, larger frame bite and stronger attachment hardware with the flexural capacity to accommodate sufficient movement to help dissipate the blast load.

Advanced Analysis

Complex glazed facades require advanced analysis tools or testing. A prime example is using dynamic analysis versus static analysis.

Two basic aspects of dynamic analysis differ from static analysis. First, dynamic loads are applied as a function of time or frequency. Second, this time or frequency-varying load application induces time or frequency-varying response (displacements, velocities, accelerations, forces and stresses).

These time or frequency-varying characteristics make dynamic analysis more complicated and more realistic than static analysis. Dynamic analysis is seen as offering the most economical approach.

Dynamic analysis tools include Finite Element Analysis (FEA) and Single Degree-of-Freedom System (SDOF).Be sure to account for coupled response in the design, Davis noted.

PEC offers a design tool known as WhAM for finite element glass analysis (Window (hazard) Analysis Module) of complex configurations. Results can be validated by comparison of predictive response of elements to actual performance under blast or shock tube test.

600450

600450

Add new comment