Date: 15 June 2016

In order to provide customers with perfectly cut and polished glass for the next 150 years, Vitralux has decided to renew it’s entire machinery by Fuldner Machines.

An efficient flow in the editing process

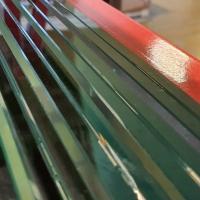

Vitralux has chosen for Turomas cutting tables for laminated glass in combination with a PLF loading table with transporting belts. Furthermore, Füldner Machines has installed a 15 spindle edging machine which can cut up to 100mm thick glass as well as a STA centrifuge for the cleaning of cooling water. On top of that, 48 Tecnocat automatic sliding shelves were delivered which give Vitralux immediate access to all common types of glass.

Sales manager Gust Verbruggen has thoroughly studied the needs of Vitralux and has played a key role in advising Vitralux in the renewal of it’s machinery. In order to ensure an efficient flow in the editing process Fuldner Machines has installed 36 Turomas sliding racks for DLF glass sizes as well as 12 slide racks for PLF glass sizes.

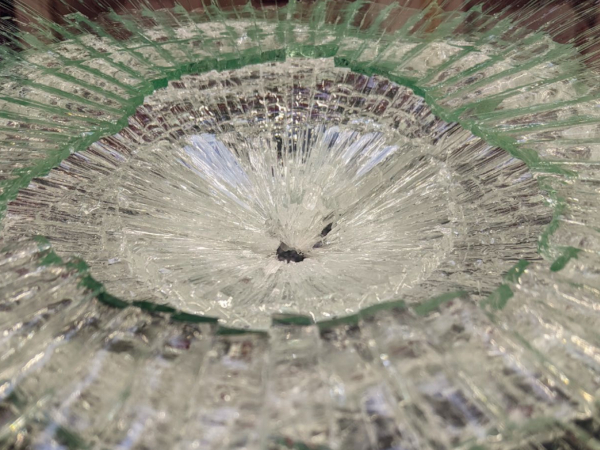

Furthermore, a Turomas PLF Loading table with transport belts was installed, connected to the newest Turomoas cutting table for laminated glass (2+2 to 15 mm+ 15mm).

A new Lattuada TLR 15 AVC is being used for cutting glass up to 100 mm tick. This machine can cut and polish flawlessly with liquid cerium oxide. Furthermore, a STA centrifuge was installed to prevent internal pollution in the machines and water containers. This modernization allows Vitralux to polish and cut all common types of glass.

600450

600450

Add new comment