Date: 21 December 2021

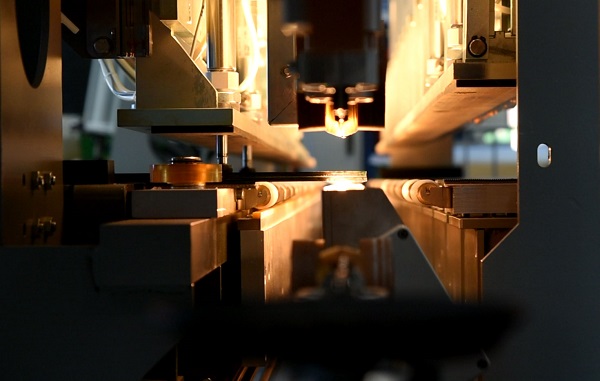

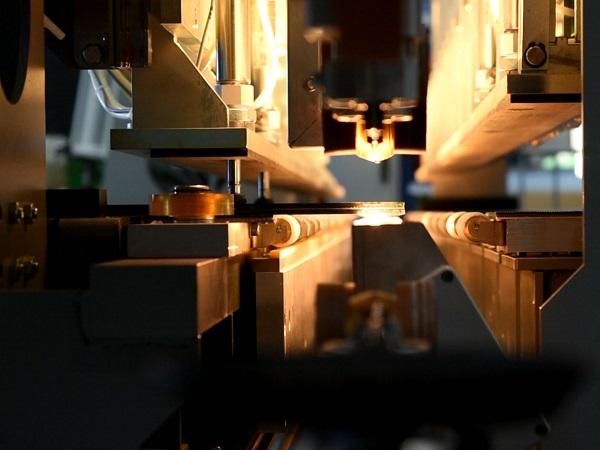

At the end of 2018, LiSEC presented its VSL-A horizontal cutting system — a basis for successful processing of laminated glass. Since market introduction, numerous customers have been inspired by its considerable increase in output, patented SIR film heater, significantly reduced glass waste, and less operator intervention due to increased automation.

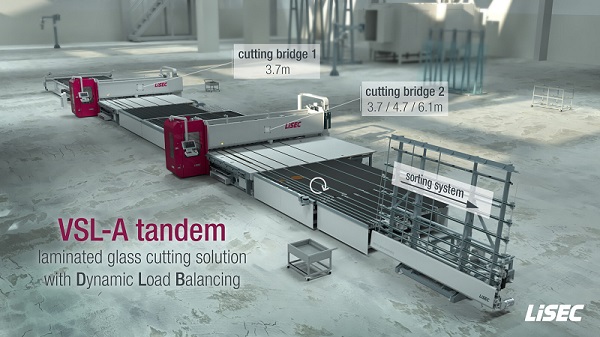

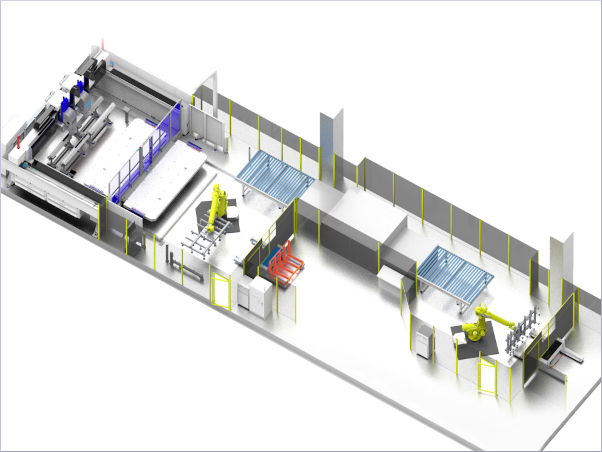

To provide solutions that best meet customers’ individual needs, LiSEC has developed a modular laminated glass cutting system solution that can be adapted and expanded step by step as required. At the final expansion stage, two VSL-A stations can be combined consecutively to cut glass to size on the second VSL-A Tandem. Together with intelligent Dynamic Load Balancing, output of up to approx. 140 units of fully cut sheets can be achieved per hour. In keeping with the motto, “If you stop getting better, you stop being good” (P. Rosenthal), over the past two years, extensive development has been done to the VSL-A’s production control logic and engineering. Daniel Schörghuber, product manager for the glass cutting department at LiSEC, introduces future solutions for almost completely automatic cutting of laminated glass with high output and perfect cut quality.

MR SCHÖRGHUBER, WHAT IS LISEC DEVELOPMENT FOCUSING ON?

Daniel Schörghuber: In developing VSL-A cutting technology, we’ve taken into account the growing portion of laminated glass, especially at companies processing insulating glass. This allows higher output in less time with reduced waste. Moreover, in the past two years, in a great deal of project planning, we and our customers have assessed their production data, analysed the situations in the production facilities, and have come to the following result: A glass storehouse usually supplies at most two to three cutting lines. Generally, there is no space for expansion width-wise without structural adaptations to the production hall. With the necessary increase in automation together with continuously high quality regardless of the raw glass quality, LiSEC’s new system solution meets market demand at a time when labour is tight. The VSL-A system solutions are the next step toward fully automatic systems. The laminated glass cutting capacity is increased by a modular concept based on VSL-A technology.

HOW IS THE MODULAR DESIGN STRUCTURED?

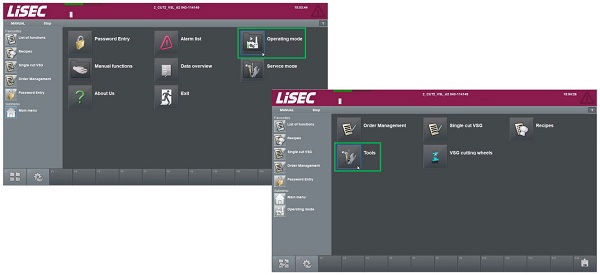

Daniel Schörghuber: It all starts with automatic glass storage in combination with a system for edge deletion or removal of the LSG film overhang, and with the first VSL-A cut with conveyor belts. Then, depending on the production quantity and variety, users can choose between two different variants. Customer Type A, who has a lot of variation in the product mix (X-Y-Z cuts) can already reach output of approx. 75 sheets an hour with an additional VSL-A station without Tandem, downstream from the first VSL-A station in line — and it’s all completely automatic. Here optimal dynamic use of the two VSL-A system solutions plays a major roller. Moreover, new operating modes have been developed and can be switched between at any time: Sport and comfort mode. When comfort mode is selected, the system continuously produces fully cut glass sheets on the conveyor belt, with almost no human intervention. Sport mode can provide additional production capacity. Here the operator assists the station, especially in separating scraps, which again makes for higher output, a special advantage during production peaks. Customer Type B, who often produces identical products (X-Y cuts), can expect a count of approx. 140 sheets per hour with a VSL-A station in Tandem design. In Tandem mode, two simultaneous sheets can be cut on the second VSL-A, automatically. This solution far exceeds all previous output numbers and represents the fastest LSG cutting system on the market, especially for series formats.

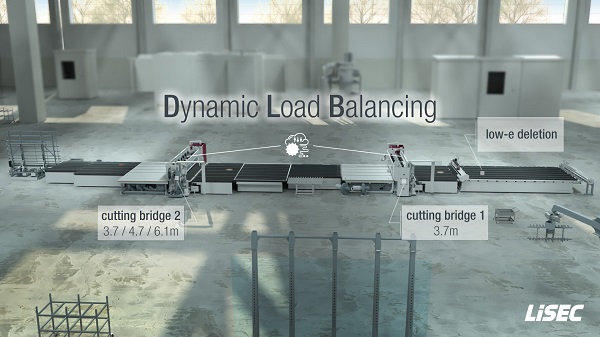

HOW DOES THE DYNAMIC LOAD PLANNING WORK?

Daniel Schörghuber: When developing two consecutive VSL-A laminated glass cutting bridges, it was especially important to us to load them intelligently and as well as possible to maximize output and reduce waste. We achieved that through mutual dynamic production control, which — depending on the specific optimization — dynamically distributes the processes on thee individual laminated glass cutting bridges. This Dynamic Load Balancing (DLB) loads the bridges in the best way possible. It reduces throughput time for each optimization and increases the hourly output of completed units.

What advantages do two consecutively arranged VSL-A laminated glass cutting bridges offer?

Daniel Schörghuber: The VSL-A cutting bridges have very high mechanical stability and therefore form the basis for consistent, precise cutting results. The first VSL-A station optionally makes the front edge cut to at least 20 mm and automatically disposes of it into a container. Then follows the X sub-plate cut, which is precisely rotated 90° by the VSL-A with its integrated rotation function and without operator intervention. The Y scrap at the trailing edge of the sub-plate is automatically removed and disposed of. The sub-plates prepared on the first VSL-A station are then further processed at the VSL-A bridge. Depending on the dynamic load plan, the first station can also make Y cuts. In the next step, the Y and Z cuts are done, and the scraps are removed without operator intervention. Then follows automatic outfeed and either removal of the finished products by an operator or automatic transfer to a downstream sorting system.

FACT BOX:

Standard functions

- approx. 45 units of trimmed sheets per hour with one VSL-A cutting bridge (X-Y-Z cuts) — fully automatic

- approx. 75 units of trimmed sheets per hour with two consecutive VSL-A cutting bridges (X-Y-Z cuts) — fully automatic

- approx. 140 units of trimmed sheets per hour with two consecutive VSL-A cutting bridges (X-Y cuts) + tandem function on second station — fully automatic

- Version with Dynamic Load Balancing (DLB) of two cutting bridges for maximum output and minimum waste

- Version with one or a maximum of two laminated glass cutting bridges with 3.7 m, 4.7 m or 6.1 m – special space-saving design

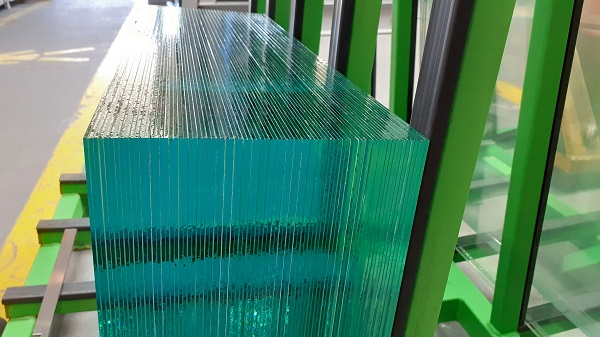

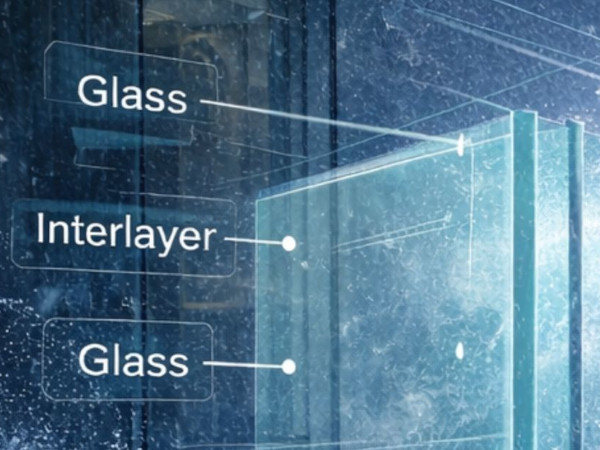

- Cutting of laminated glass from 22.1 (4.38 mm) to 1212.12 (28.56 mm) glass thickness, with precision of +/- 0.4 mm and up to 140 m/min cutting speed

- approx. 10% higher edge strength through reduced heat transfer into the glass thanks to a patented SIR heater, the cutting wheel design and pressure regulation

- Up to at least 20 mm fully automatic cutting, breaking and separating of laminated glass

- Automatic sub-plate rotation to the maximum dimensions and maximum glass thickness

- Electronic cutting pressure control and cutting wheel consumption analysis

- Very low maintenance and high system availability

- Simple operation thanks to a graphic touchscreen interface

Optional functions

- Cutting of custom shapes and W sub-plates

- Automatic processing of float glass and two-sided film coated float glass possible — cutting, film separation and breaking

- Rotating device for finished cut glass sheets for automatic connection to a sorting system

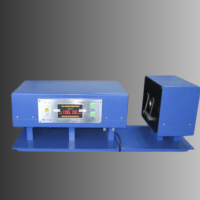

- Version with automatic laminated glass scrap disposal (GSA-A) — laminated glass scraps are crushed quietly and dust free, and disposed of in handy containers

- Expansion option from one cutting bridge (VSL-A) to a system solution with two VSL-As and a tandem option

Highlights

- Fast, flexible cutting of LSG

Using a VSL-A system solution with two cutting bridges extended with dynamic load balancing (DLB), allows the VSL-A Tandem to provide continuous high output and process safety under any conditions. Depending on the version (with or without the Tandem option) and optimization (cutting plan), this allows up to approx. 140 completed sheets per hour. - Fully automatic production

Laminated glass is cut, broken and separated entirely automatically. Rotation and further feed requires no operator intervention. Complete cut laminated glass is consistently delivered. Laminated glass just in time — the result is cutting independent of operator and environmental influences. - Consistently high-quality cutting results

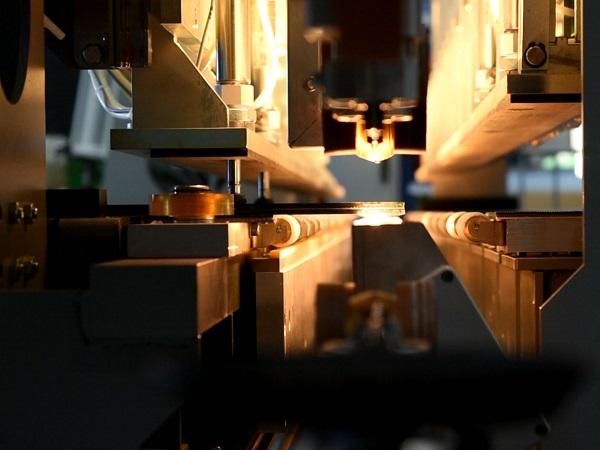

The SIR film heater is specially developed for current and future laminated glass cutting requirements, reduces heat stress to the cut edges and ensures at least approx. 10% greater edge strength. Double precision-guided cutting heads with direct drive and dynamic cutting pressure control, including cutting wheel consumption monitoring, reducing oblique breaks and sliver formation, and forming the basis for successful cutting of LSG without scratches, and significantly reducing grind additions.

600450

600450

Add new comment