Date: 29 May 2020

This moment of great difficulty makes us understand how it is increasingly important to rely on advanced solutions and technologies, aimed at automating activities and increasing production flexibility.

This moment of great difficulty makes us understand how it is increasingly important to rely on advanced solutions and technologies, aimed at automating activities and increasing production flexibility.

The contribution that robotics and automation can make in supporting the recovery is more decisive than ever.

Adelio Lattuada has been studying and developing customized solutions for every need for years.

In this second NL the focus is on the CyberAL project.

CYBERAL, AUTOMATION AND INTERCONNECTION FOR A TRULY INTEGRATED INDUSTRIAL PRODUCTION

CYBERAL, AUTOMATION AND INTERCONNECTION FOR A TRULY INTEGRATED INDUSTRIAL PRODUCTION

Robots, automation, integration, Industry 4.0: glass processing steps into a new era.

Those who opt for advanced solutions and technology can count on an effective competitive edge. Right from today, Adelio Lattuada will by your side to help you achieve this new production and flexibility goal through CYBERAL.

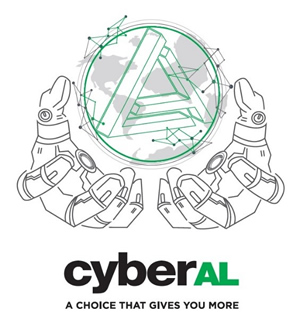

A-WR SYSTEM

Tired of performing wheels presetting on straight-line edgers? Our A-WR system is the answer!

- automatic pre-setting “ZERO” procedure of diamond and resin wheels, without glass and in less than one minute

- automatic recover of the polishing wheels’ wear

- automatic positioning for the wheel’s replacement

- Jog increase/decrease of the spindle position (accuracy 0.01 mm).

- automatic positioning on setpoint

- automatic backlash recovery

- automatic spindle cleaning procedure wheels wear warning

- spindle’s problems warning

- manual unlocking for any situation

WATCH THE VIDEO, CLICK HERE

FULLY AUTOMATIC MACHINE

- A-WR SYSTEM

- digital ammeters and automatic alert system for the polishing wheels wear

- brakes on all polishing spindles for the recovery of the wheels wear

- automatic management of thickness, pressure, removal and speed

- management of the working phases through a touch-screen panel

- new assistance service with AR (Augmented Reality)

- proportional valves for pressure regulation of the polishing spindles

- motorized glass removal with portable push-button panel

- glass length measurement

- new progressive lubrication system

- teleassistance and remote support

- data-logging and IOT

WATCH THE VIDEO, CLICK HERE

600450

600450

Add new comment