Date: 17 December 2024

Sparklike Handheld offers a straightforward method for assessing the argon levels in argon filled glass. Below, we outline the specific steps and considerations involved in performing a measurement, based on the guidance in the device’s manual. Read more Support tips on our FAQ pages.

Guide to Measuring Argon Filled Glass

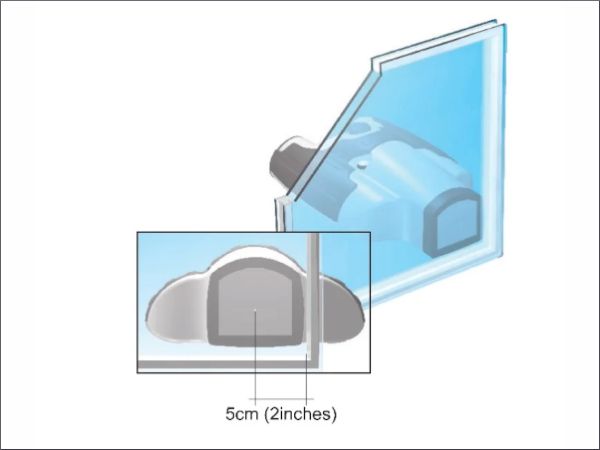

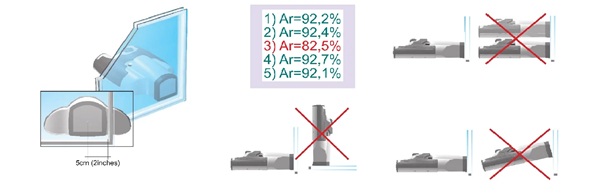

Positioning the Device

Place the Sparklike Handheld close to the spacer bar, as it helps the spark to ignite. The device’s center should be approximately 5 cm (2 inches) from the spacer’s inner side. Ensure the device is flush against the IGU to avoid inaccurate readings. Also ensure that there is no space between the Handheld and IGU.

Keep the IGU Upright

Measurements are more stable when the IGU is upright, reducing the erratic behavior of the spark caused by the Earth’s magnetic field. This positioning also minimizes potential damage to low-emissivity (Low-E) coatings.

Avoid Movement During Measurement

Hold the device steady during the two-phase measurement process (background and spark). Movement can disrupt the measurement, leading to unreliable results.

Repeat Measurements if Needed

Perform two to three measurements at the same spot for better accuracy. However, move the device slightly for repetitive measurements to avoid damaging the Low-E coating.

Factors Influencing Measurement Accuracy

Glass Properties

- Glass thickness exceeding 6 mm, or the presence of laminated glass, can hinder the spark. A metallic spacer or thin air space (≤20 mm) aids the spark ignition.

- Glass with metallic coatings on surface 1 (the measured side) prevents measurement as the spark cannot penetrate the coating.

Environmental Conditions

- Stable lighting is crucial; too much background light can drown the argon signal. Avoid measuring against sunlight or bright lamps.

- Ensure the IGU surface is clean, and the device’s optics are undamaged for consistent results.

IGU Restrictions

Certain IGUs present challenges or cannot be measured due to their construction. Common restrictions include:

- Tinted or solar-controlled glass with metallic components.

- Laminated glass with thick layers or poor gas conductivity.

- Triple glazing units where the spark cannot reach the insulating gas layer.

For specialized IGUs, consult with your Sparklike distributor to determine feasibility.

Common Troubleshooting Tips

Weak Spark Signal: Ensure the spark hits through the window. Adjust positioning if needed.

Overexposure: Reduce surrounding light intensity to prevent sensor overload.

Low Concentration Detected: The measured concentration might indicate leakage or an unfilled IGU.

By following these guidelines, you can maximize the performance of the Sparklike Handheld to ensure accurate gas fill readings in argon filled glass, maintaining high-quality standards in IGU production and installation.

More support for Sparklike Handheld.

Contact Sparklike for more information and support on measuring argon concentration in IGUs.

600450

600450

Add new comment