Date: 13 March 2015

To increase production capacity, improve quality and maintain the highest level of customer service, Senior has recently invested £1 Million in new software and equipment.

The upgrade is now complete and all equipment and software is operational with operatives fully trained to maximise performance of the glass manufacturing facility, allowing customers to benefit from these three major improvements:

New Heat Soak Oven – Heat soaking is a requirement of many architectural specifications and the new heat soak oven enables Senior to bring this vigorous quality assurance technique in-house reducing the risk of toughened glass units spontaneously cracking due to the rare nickel sulphide phenomenon. Whilst toughened glass is safer than normal glass there is still a small danger that the glass will spontaneously crack and break. This is because glass contains Nickel Sulphide (NiS) which can become unstable when heated. By putting the toughened glass through the heat soak oven any glass containing unstable NiS will break in the oven, so that there is less risk of supplied glass spontaneously cracking or breaking once installed on site.

.jpg)

The new commercial furnace can produce larger sheets of toughened glass

New Commercial Toughening Furnace –The new furnace became fully operational on 12th February and will allow Senior Glass to produce larger glazed units, improve capacity and significantly reduce lead times. In fact the furnace will be able to toughen glass up to 2500 x 3200mm which can then be manufactured into double glazed units up to a maximum weight of 300Kg..jpg)

The new heat soak oven brings added quality assurance

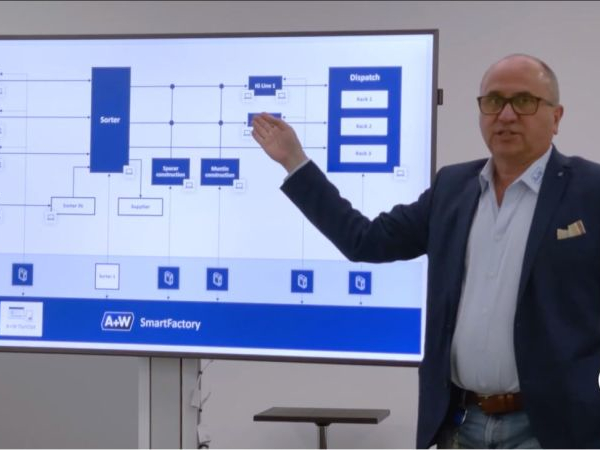

New Material Resource Planning (MRP) Software – The new MRP Software went live on the 2nd February and is now being used to process all new orders. The new software gives greater visibility of orders and resources, allowing Senior Glass to keep a tighter control on delivery dates. Going forward a tracking system will be introduced so that it will be possible to let customers know exactly how their order is progressing.

.jpg)

The new commercial toughening furnace with fully trained team members

Senior expects the new heat soak oven and commercial furnace to boost glazed unit production by up to 60% and an extra 12 staff have been employed to handle the increased output.

Operations Director Michelle Damms said “We are delighted with the improvements that have been made at Senior Glass. Thanks to careful planning and the hard work of the Scarborough team, disruption to production and customer service has been kept to a minimum. We would like to thank all our customers for their ongoing business and support during the upgrade which will improve lead times, quality assurance and customer service in the future.”

Add new comment