Date: 26 May 2025

The glass industry is at a turning point. The shift to fully automated, interconnected factories is happening now, and the key to success lies in software solutions that seamlessly integrate machines, production workflows, and logistics. A+W is at the forefront of this transformation, offering cutting-edge solutions that empower glass manufacturers to optimize production with fewer workers on the shop floor.

A+W Smart Companion Production: Digital Assistance at Every Step

In an automated plant, efficiency starts with real-time production data. A+W Smart Companion Production puts essential production insights directly in the hands of workers through mobile devices, reducing paperwork and manual errors. It allows operators to scan, track, and confirm production steps, ensuring that every piece of glass moves smoothly through the workflow with full digital traceability.

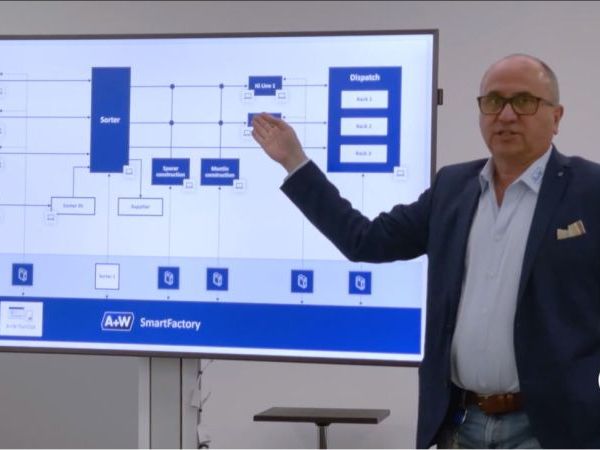

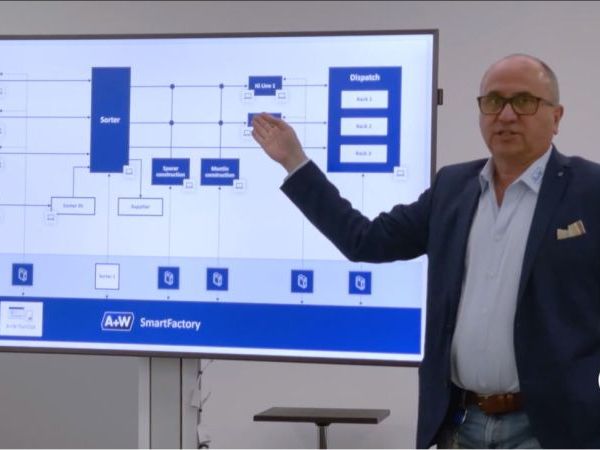

A+W Smart Factory: The Heart of Interconnected Production

A true smart factory requires a Manufacturing Execution System (MES) that seamlessly connects machines and workflows. A+W Smart Factory optimizes production by:

- Automating scheduling and job sequencing

- Dynamically adjusting machine settings in real-time

- Integrating with IoT sensors for predictive maintenance and quality control

By eliminating manual intervention, A+W Smart Factory ensures maximum efficiency, reduced downtime, and streamlined operations.

A+W Smart Delivery: Precision Logistics for the Automated Plant

Automation doesn’t stop at production. A+W’s Smart Delivery system ensures that finished glass is loaded, tracked, and delivered with the same level of precision as production. With real-time route optimization and digital confirmations, Smart Delivery enhances logistics efficiency, reducing delays and misloads.

Why This Matters for Glass Manufacturers

By implementing these smart solutions, glass manufacturers can:

- Reduce labor dependency while increasing efficiency

- Minimize errors through real-time tracking and automation

- Improve production transparency with full digital traceability

- Enhance customer satisfaction by ensuring on-time, accurate deliveries

The Future is Here

The automated plant is no longer a concept—it’s a necessity for manufacturers who want to stay competitive. A+W’s solutions are designed to make this transition seamless, ensuring that interconnected software and smart machines drive efficiency, accuracy, and profitability.

Are you ready to take your glass plant to the next level? Explore A+W’s automation solutions today at www.a-w.com.

600450

600450

Add new comment