Date: 10 February 2022

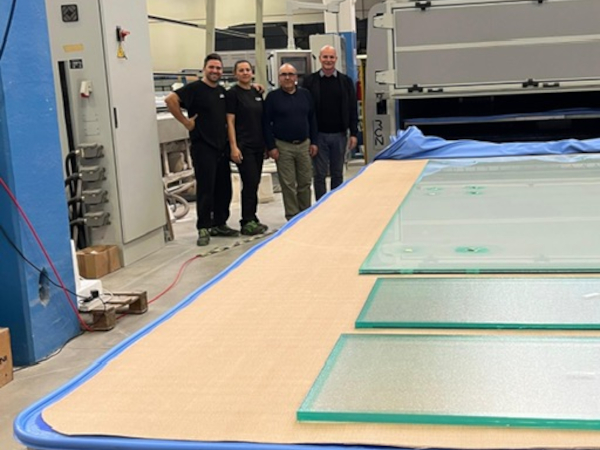

sedak has extended its production capacity in the field of curved glass. With the start of operation of its new 18m bending furnace, the glass processing company is setting new standards in thermal glass bending and has underpinned its technological leadership for large-format functional glazing.

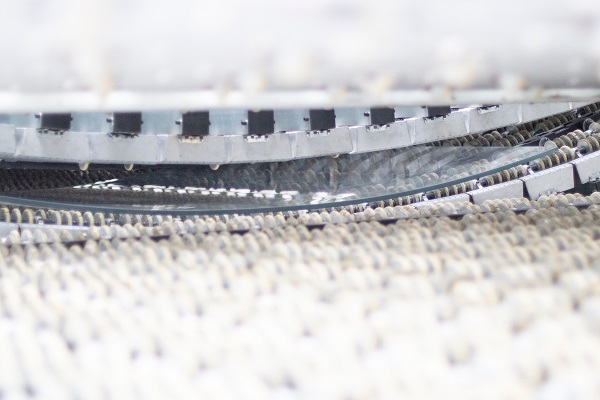

The new sedak bending furnace is designed for series production of cylindrically curved, fully tempered glass and thermally toughened glass in (over-)large formats of up to 3.6x18 meters. The bending and tempering thereby takes place in a single production process. New technology enables the fast and precise adjustment of the bending radius, so that glass for projects requiring various geometries can quickly be produced. Depending on the width, glass can be curved to a minimum radius of 1,000 millimeters.

The first orders are already running on the sedak bending furnace. The production of a large project with glass of up to 11 meters in length is set to take place in early summer 2022.

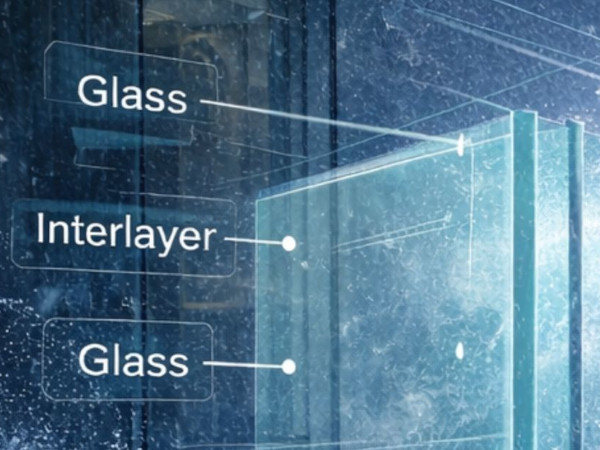

sedak offers the complete spectrum of curved glass in almost any form. The glass panes are produced in a suitable process depending on the glass geometry. In addition to thermal bending of fully tempered glass and thermally toughened glass, sedak offers lamination bending for glass of up to 20 meters and the gravity bending process for almost any architectural free-form. The curved glass is further processed to safety glass and insulation glass and, just as for flat glass, this can be put through the complete sedak processing spectrum from gold printing to bullet-resistant glass.

Further information: sedak.com

600450

600450

Add new comment