Date: 26 July 2018

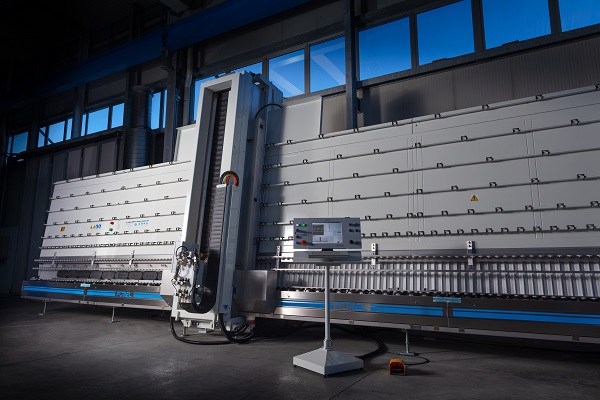

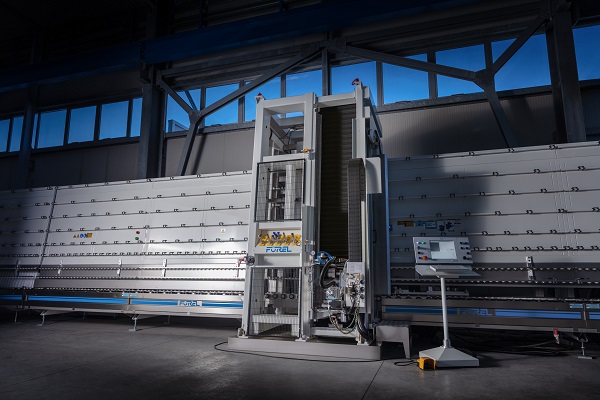

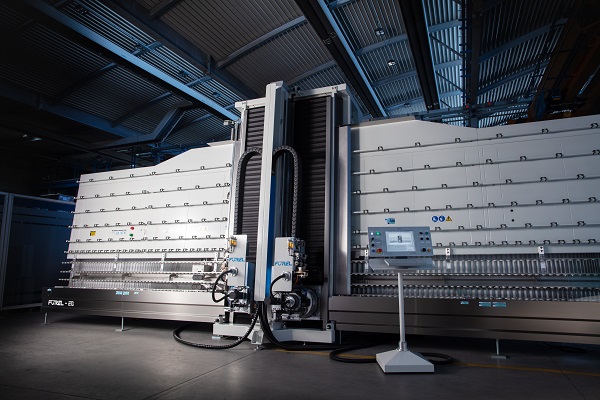

The "No Limits 9000" IG line represents the further step of Forel in the oversized insulating glass units, following the market trend that favours the use of bigger glasses for façades. A trend that is reflected today in some of the most modern architectures in the world.

Despite its innovative features compared to the previous Jumbo lines, the "No Limits" 9000 line is a guaranteed product with higher production capacity obtained thanks to the improved combination of well-established technical solutions.

The first element to note is obviously the size capability of the new line, which allows to process panes up to 9 meters long and 3.30 meters high, with a load capacity per linear meter that reaches 350 kg for the single pane and 550 kg for the assembled panes.

The dynamic support system in the coupling press allows to process multiple chambers and to create vertical offsets of up to 250 mm and horizontal offsets of up to 1000 mm.

A series of applications on every single machine included in the line lets the operator successfully manage significant curvatures of the glasses.

COMPOSITION

LINE SERVER INTERFACE (PLUS VERSION): consisting of a PC station at the beginning of the line, it is based on a special software which ensures communication between all the machines involved, thereby optimizing the production processes.

Art. VW WASHING MACHINE: for a complete and precise washing, through three different processes: pre-washing (spray ramp), washing (8 brushes, diameter 225 mm), rinsing (spray ramp). To provide the most suitable washing for each type of glass, the Art. VW washing machine is equipped with an automatic lowemissivity coating detection system.

It is made entirely of austenitic stainless steel and is equipped with a water heating system that can reach up to 60 °C. The drying area is equipped with 2 inclined blowers, powered by a high head fan and sound-absorbing panels.

Art. SQD331 QUALITY CONTROL SCANNER AND INSPECTION CONVEYOR: Quality control, especially when working on oversized dimensions, becomes a fundamental element of insulating glass production. As well as identifying any imperfections in the pane, the Art. SQD331 can also archive the results of its scan: in this way it is possible to certify the conformity and the quality of the product, even at a later date.

Art. TT TILTING TABLE: performs a tilting movement to allow the panes to be unloaded. The Tilting Table is of significant dimensions (max glass size 3300 mm in height x 4000 in width) and, combined with the air cushion generated by an electric fan, allow easy handling even when processing large sheets.

Art. ARC TURNING CONVEYOR: capable of turning sheets up to 6 metres long.

Art. APG COUPLING FLAT PRESS WITH GAS FILLING: the coupling press installed in the "No Limits" 9000 IG line has been designed considering that often oversized dimensions can correspond to significant planarity unevenness (also in terms of centimetres). In order to guarantee optimal processing with panes up to 9m long, Forel has developed and patented an exclusive system of retractable suction cups, able to straighten any planarity unevenness.

The two sheets that make up the panel (whether single or laminated glass) are held in such a way as to ensure they remain perfectly aligned, so that the gas filling slot is uniform. Once the gas filling phase has been completed, the two panes are pressed so as to obtain an airtight closing of the chamber.

Art. APG can withstand significant vertical offsets, up to 250 mm, also when processing double or triple insulating glass.

Art. SRHP SEALING ROBOT HIGH PERFORMANCE: capable of handling up to 3 sealant products and equipped with a semi-automatic dosing unit change, the sealing robot can operate on panels up to 9 meters long. This has been made possible thanks to an innovative sealing head, which takes into account the probable curvature of oversized sheets.

In fact, the nozzle of the extrusion head can follow any deviations and imperfections of the panel thanks to a dynamic detection device , which detects the geometry of the panel and consequently controls the extrusion of the sealant through actuators. Art. SRHP therefore offers perfect sealing under any circumstances and also in the presence of curvatures, surpassing the performance levels of any previous models.

EDGE PROCESSING

Art. EM-DM – Arrissing, grinding, polishing, drilling, milling

The Art. EM-DM line developed by Forel is the ideal combination for arrissing, rough-edge grinding, polished-edge grinding, drilling and milling.

The edging machine is equipped with a patented suction cups system for a stable hold of the glass, that guarantees perfect positioning and absence of vibrations, besides allowing the processing of any lowE glass. With square or rectangular pieces, it can operate in self-learning mode, thanks to a special feeler installed in the head.

The vertical drilling and milling is equipped with an exclusive combined system of fixed and movable suction cups to hold the glass and comes with a specific dynamic suction cups device for a precise and safe processing of large cut-outs.

Art. EG – Double head Arrissing Machine

Accurate and reliable, the Art. EG arrissing machine is equipped with two operating heads capable of working simultaneously: a significant increase in productivity, operating simultaneously on two different pieces or synchronized on a single piece.

Processing of square and rectangular pieces is carried out in "self-learning" mode: through the use of a series of measuring photocells, the Art. EG arrissing machine automatically acquires the dimensions and the thickness of the glass.

SORTING SYSTEM

Art. SS – Sorting System

The Sorting System is the Forel's solution for optimising displacement, handling and storage of the glass sheets inside the Factory.

Thanks to its modularity, it can also be easily introduced into existing plants, linking different processing areas, avoiding manual handling and thus minimizing the risk of glass breakage or damage.

Composed by one or more mobile shuttles and storage warehouses, the Art. SS leads to an immediate increase in productivity and efficiency.

VERTICAL CUTTING LINE

Art. VC02 - Vertical cutting line for laminated glass

A solution for cutting laminated glass capable of guaranteeing high productivity even optimizing the space inside the glass factory. Equipped with two cutting bridges and an impressive turning section, the vertical cutting line Art. VC02 can process Jumbo sized sheets and cut on the three axes, X, Y and Z.

Each bridge consists of two opposing incision carriages and two breaking bars to cut and open the glass sheet along its entire height. The split is supported by a special motorized ironing system (patented by Forel). Both bridges can be equipped with LowE coating removal system.

INSULATING GLASS

Art. CRP – Double Head Coating Remover

The double-head Art. CRP coating remover allows to uniformly remove the Low-emissivity coating from the glass surface, thanks the possibility of self-regulate the peripheral wheel operating pressure.

The coating removal speed can be set according to the type of coating to be removed, the type of abrasive wheels used and their degree of wear.

With square or rectangular pieces, the Art. CRP can work automatically by acquiring the sheet dimensions and thickness through a series of specific sensors.

Art. PBA632 – Profile Bending Machine

The Art. PBA632 is equipped with the special Smart Arm (patented by Forel), which accompanies and supports the spacer during bending operations.

In fact, the Smart Arm reduces to the minimum any risk of profile deformation or breakage, even when processing oversized spacers, thus ensuring safe processing and high productivity.

Furthermore, the machine has been recently upgraded with a specific device for plastic profile bending.

The Art. PBA632 can carry out the classic internal bend or an internal bend at 90°, aesthetically identical to the welding joint or the corner bracket (corner keys), but with production times lower than the former and without the heat loss typical of the latter.

Art. DFN632 - Desiccant Filling Machine

The desiccant filling machine Art. DFN632 allows to automatically fill the profile frames with hygroscopic material in order to prevent the formation of condensation inside the insulating glass panel. This solution consists of a turret on which a frame-pressing vice and two special drilling and filling heads are installed.

After drilling the frame, using two drills positioned at 90° from each other, the drying material is inserted by a jet of compressed air. Once the filling is complete, the two holes are sealed using butyl.

The machine can process both rectangular and shaped frames.

600450

600450

Add new comment