Date: 20 January 2021

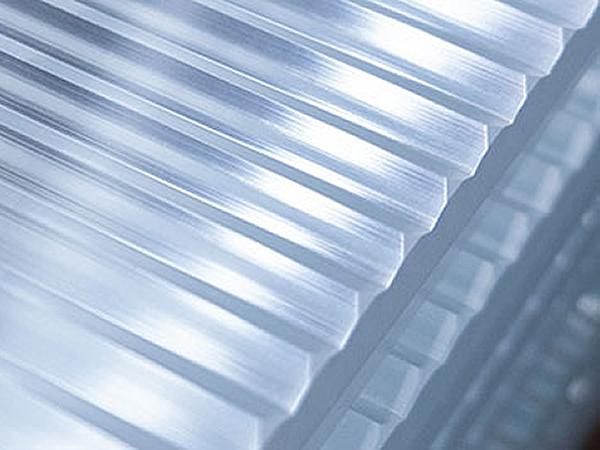

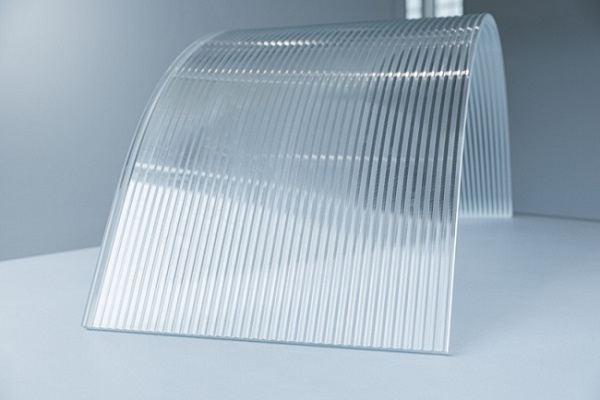

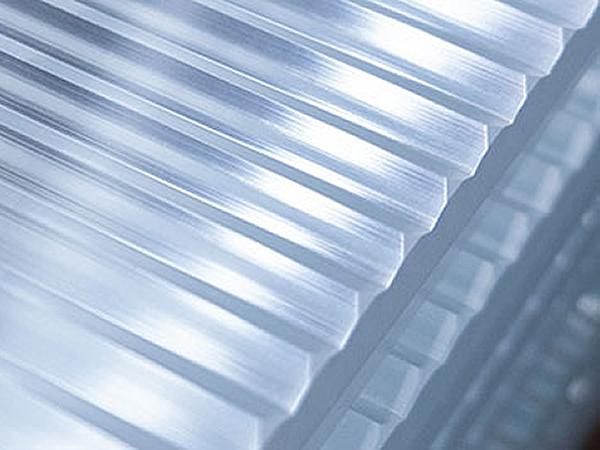

With the new grinding unit for the processing center unique grooves can be worked in glass up to 20 meters now. In addition to a C- or V-shaped form, the spacing and depth of the grooves can also be varied. The grooves can run lengthwise or crosswise. Thanks to digitization, a wide variety of design options can be realized.

Due to the precision of the processing, the grooved glass is not only a transparent privacy screen, but the brilliant edges make the grooved glass the optical highlight of every glass facade or a exquisite room divider.

The grooved glass can be tempered and processed into flat or curved safety and insulating glass. The glass is available in sedak maximum dimensions up to 3.6 x 20m.

600450

600450

Add new comment