Date: 3 July 2019

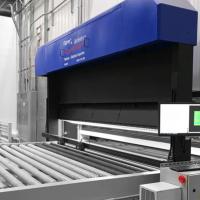

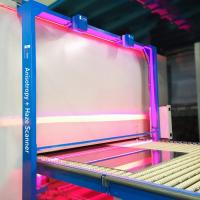

With the SOFTSOLUTION / GLASS IQ scanner, inspections are carried out according to the international norm and the fragmentation test can be processed easily and quickly.

In addition, the CulletScanner is used for laboratory work in the automotive industry as well as for the exact evaluation of the glass fragments.

600450

600450

Add new comment