Date: 4 April 2019

It has been that way since 1941, when Duralux protective coatings led the way to the company’s international acclaim. And it is still that way today, with a top-level manufacturing plant in Vilvoorde, Belgium - that interfaces seamlessly with the advanced mirror products research lab - now even broader-based to host its constantly growing production.

Developed at the expertise center of the mirror business unit, Luxver is a complete line of chemical products for glass silvering. It is easy and ready to use, and engineered to satisfy the highest safety standards. As with all Fenzi mirror-manufacturing products, Luxver delivers an exceptionally durable and safe end-product with highly reflective silvering that is uniform, very brilliant and corrosion-resistant. Alongside the very popular Duralux range, Luxver rounds out a family of high-quality products that cover the entire production process for all types of mirrors.

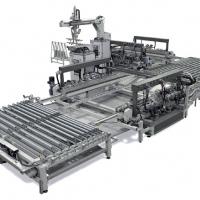

Building on the success of this unique set of products, and to meet growing market demand, Fenzi Belgium recently inaugurated a new area dedicated to Luxver manufacturing and research. The highly efficient structure has already obtained ISO 9001:2015 quality certification, confirming once again the extensive experience Fenzi has amassed in the field of mirror products.

The new manufacturing area is only one of the puzzle pieces that tell the story of Fenzi’s ongoing, dynamic growth, from the earliest days. In more than 75 years of business, the Group has become a global leader in glass-processing chemicals, offering a complete range of products and setting the standard for the entire glass industry.

“The mirror-backing paints business unit that has expanded its range to include chemical products for silvering is of paramount importance to the entire Group, even in terms of sales volume, – states Alessandro Fenzi, CEO of the Group - Thanks to our considerable innovative prowess, based on know-how acquired in nearly 80 years in this industry, and on research and development activities consistently focused on customer needs, we have managed to create a complete product range, positioning ourselves as the preferred partner for mirror manufacturers around the world. This investment is a direct result of the huge demand for Fenzi products, and of the corporate objective to always work closely with our customers in order to provide them with the best possible service”.

600450

600450

Add new comment